Polycarbonate Injection Molding

Erye Offer Polycarbonate Plastic Molding Service to Specific to Your Needs!

- Low-volume and high-volume production

- Small to large part size

- Free & fast DFM report

- No mininum order quantities

- T1 samples as fast as 10 days

PC Injection Molding Services

| Service | Details |

|---|---|

| Maximum Part Size | 2500mm x 2000mm (98 in. x 78 in.) |

| Recommended Wall Thickness | 1.2mm - 3.5mm (0.0472 in. x 0.1378 in.) |

| Color Options | Any color according to RAL or Pantone Code |

| Standard Finishes | SPI and VDI |

| Mold Ownership | Customer owned with mold maintenance |

| Mold Life | Unlimited (If the Polycarbonate mould worn out, Erye will cover the cost of new mold) |

Injection Molded Polycarbonate Designguide

| Item | Description |

|---|---|

| Uniform Wall Thickness | Maintain consistent wall thickness (ideally within 10-15%) to minimize warpage and uneven shrinkage. Avoid abrupt transitions; use fillets. |

| Minimum Wall Thickness | For structural PC parts, aim for at least 1.5mm wall thickness, but consult material data sheets for specific recommendations based on part size and complexity. |

| Coring Thick Sections | Core out sections thicker than 6mm to promote uniform cooling and prevent sink marks. Maintain a minimum wall thickness of 1mm in cored areas. |

| Rib Design | Use ribs (40-60% of adjacent wall thickness, spaced 3-5 times the wall thickness) to stiffen thin walls. Fillet rib bases to reduce stress. |

| Boss Design | Limit boss diameter to twice the wall thickness to avoid sink marks. Blend the boss base smoothly into the wall. Consider coring larger bosses. |

| Draft Angle | Use a minimum 0.5° draft (1-2° preferred for textured parts) for easy ejection. |

| Fillets & Radii | Use generous fillets and corner radii (at least 0.5mm) to reduce stress concentrations and improve strength. |

| Shrinkage | Account for PC's shrinkage (0.5-0.8% typical) in mold design. Consult material data sheets for specific shrinkage values. |

Start Polycarbonate Molding Project

Injection Molded Polycarbonate Material Properties

| Property | Description | |

|---|---|---|

| Mechanical Properties | ||

| Tensile Strength | High (65-75 MPa) | |

| Impact Strength | Very high, even at low temperatures (Notched Izod: 600-850 J/m) | |

| Flexural Strength | Flexural Strength | |

| Elongation at Break | Moderate (100-150%) | |

| Thermal Properties | ||

| Glass Transition Temperature (Tg) | High (145-150 °C) | |

| Continuous Use Temperature | Up to 120-130 °C | |

| Thermal Conductivity | Low (0.2 W/mK) | |

| Optical Properties | ||

| Transparency | Excellent, high light transmission | |

| Refractive Index | 1.58-1.59 | |

| Chemical Properties | ||

| Chemical Resistance | Good resistance to many acids, bases, and oils. Poor resistance to strong solvents and some hydrocarbons. | |

| Water Absorption | Low (0.15-0.35%) | |

| Others | ||

| Density | 1.2 g/cm3 | |

| Flammability | UL94 V-0 to V-2 (depending on grade and thickness) | |

Applications of Polycarbonate Molding

Automotive Industry

- Headlight Lenses

- Interior Panels

- Glare Shields

- Vehicle Exterior Components

- Sunroofs and Windows

Electrical Electronics

- Electrical Insulation Components

- Connectors and Housing for Electronics

- Circuit Breakers

- Electrical Switches

- Cell Phone Covers

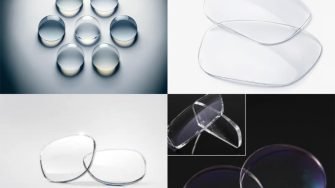

Optical and Imaging

- Lenses for Cameras

- Projector Lenses

- Optical Lenses for Watches and Glasses

- LED Light Covers

- Optical Housings and Reflectors

Aerospace and Defense

- Clear Packaging Materials

- Food Containers (for high-heat applications)

- Cosmetic Packaging

- Medical Product Packaging

- Plastic Bottles and Jars

Case Study of Automotive Car Dashboard Molding

Additonal Options for Polycarbonate Part

What is PC material

Polycarbonate (PC) offers a unique combination of properties that set it apart from other plastics. PC is often used in applications that require both strength and clarity because of its remarkable transparency and high impact resistance. PC molding parts are easy to have intricate shapes without losing their toughness.

Unlike many other standard plastics, polycarbonate’s exceptional optical clarity enables it to maintain transparency even in thicker sections, which is why injection molded polycarbonate is often used for products like lenses, light covers, and protective screens.

Key Properties that Distinguish Polycarbonate (PC) from Other Plastics:

- Exceptionally clear, nearly glass-like transparency

- Extremely high impact resistance, even at low temperatures

- Withstands high temperatures without warping

- Excellent electrical insulation properties

- Resists a wide range of chemicals and solvents

Polycarbonate Manufacturing Process

Standard Injection Molding

- Overview: The traditional process for shaping polycarbonate parts.

- Application: Ideal for creating complex geometries and high-volume production.

- Key Considerations: Requires careful temperature control and molding parameters to maintain material properties.

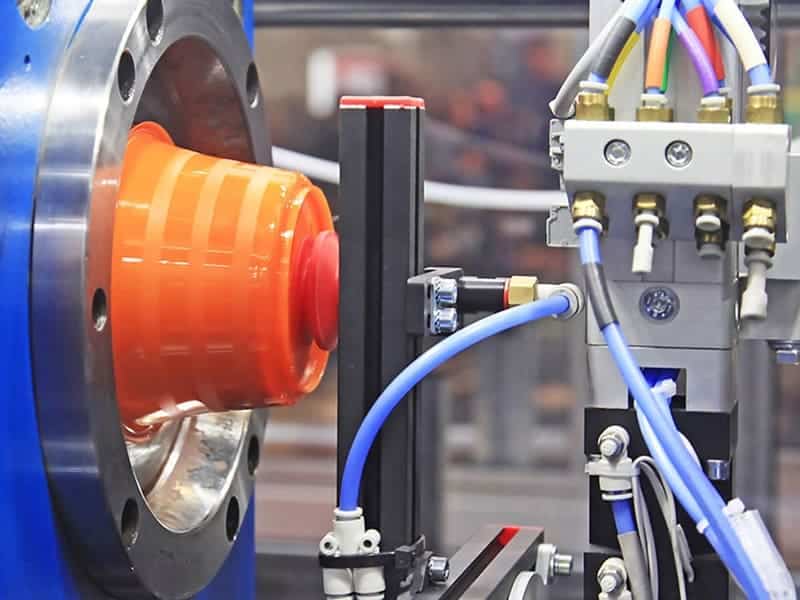

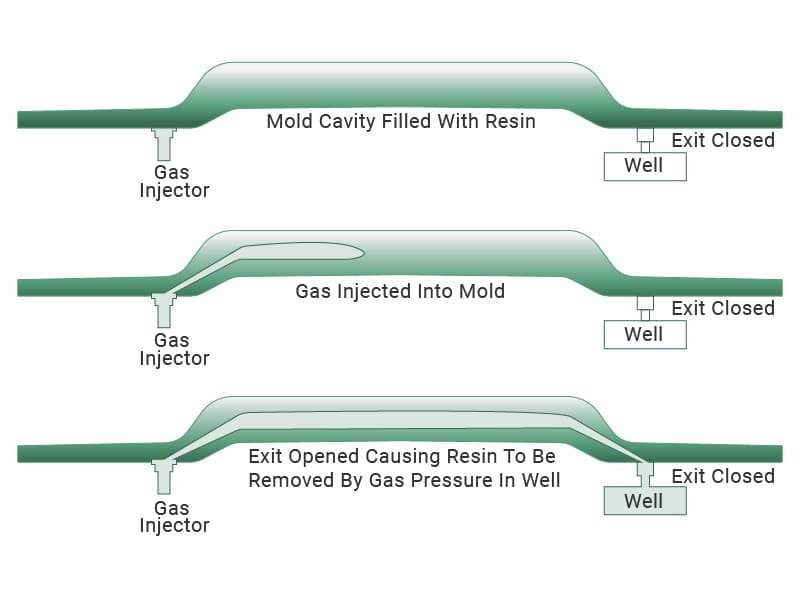

Gas-Assisted Injection Molding

- Overview: A technique where gas is injected into the mold to create hollow or lightweight parts.

- Application: Used for large, thin-walled PC parts where weight reduction is important.

- Key Considerations: Helps reduce material usage and cycle time but requires precise control to prevent defects.

Overmolding

- Overview: A process where a layer of PC is molded over a substrate, such as metal or plastic.

- Application: Used to enhance the mechanical properties or provide a better aesthetic finish.

- Key Considerations: Requires careful selection of compatible materials to ensure proper adhesion and bonding.

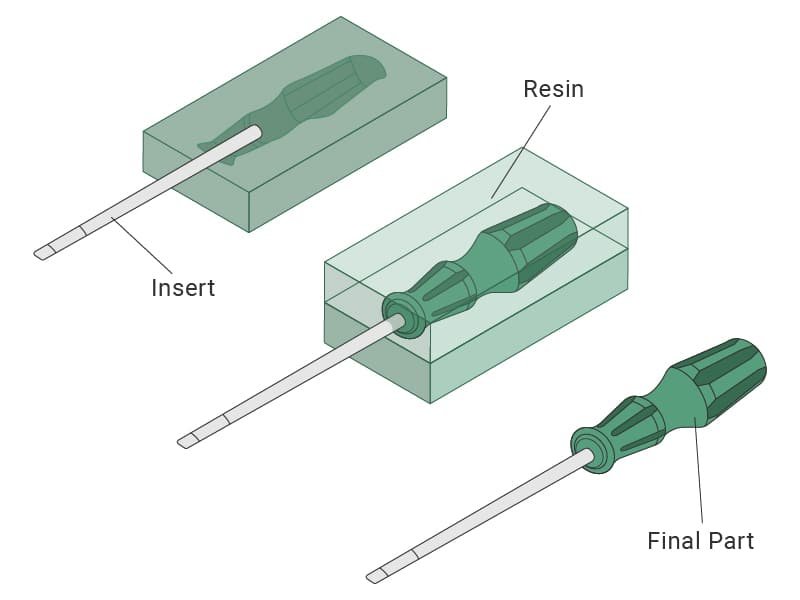

Insert Molding

- Overview: Involves placing a pre-made insert (usually metal) into the mold before injecting the polycarbonate.

- Application: Often used for parts that require threaded inserts or areas where extra strength is needed.

- Key Considerations: Ensures a solid bond between the insert and the PC material; precise mold design is crucial.

Thin-Wall Injection Molding

- Overview: A high-speed molding technique used to produce parts with walls as thin as 0.4mm.

- Application: Ideal for producing lightweight, high-clarity PC parts such as lenses and consumer electronics casings.

- Key Considerations: Requires fast cooling rates and precise injection control to avoid warping or sink marks.

Micro Injection Molding

- Overview: A precision molding technique for producing very small PC parts with intricate details.

- Application: Common in medical devices, electronics, and automotive components.

- Key Considerations: Requires specialized equipment and molds to handle fine details at small scales.

Features of Molded Polycarbonate

Advantages of Molding PC

- High Impact Resistance: PC is known for its ability to withstand high impact, even at low temperatures, making it suitable for tough, durable parts.

- Transparency: Offers optical clarity, ideal for applications requiring transparent parts (e.g., lenses, covers, and light diffusers).

- High Heat Resistance: It can withstand temperatures up to 135°C (275°F) without deforming, making it ideal for applications in high-temperature environments.

- Excellent Dimensional Stability: It retains its shape and size even under stress, ensuring consistent performance in complex and precise components.

- Good Electrical Insulation: PC has excellent electrical insulating properties, making it suitable for electronic components and insulating housings.

Disadvantages of Molding PC

- Susceptible to Scratching: While it’s highly impact-resistant, PC is prone to scratching, especially on its surface, which can affect its appearance and performance

- UV Sensitivity: Polycarbonate is sensitive to UV radiation, leading to the yellowing and degradation of its properties unless UV inhibitors are added.

- High Material Cost: Polycarbonate is generally more expensive than many other plastics, like ABS and PP, which may affect cost-sensitive projects.

- Tendency to Warp: If not processed correctly, PC can warp or distort, particularly in thin-walled sections, due to uneven cooling.

Have a Question?

Related Polycarbonate Molding Blogs

It is important to avoid common mistakes in plastic material selection during the injection molding process. It is a

Knit lines in injection molding are common plastic molding defects that can significantly affect the

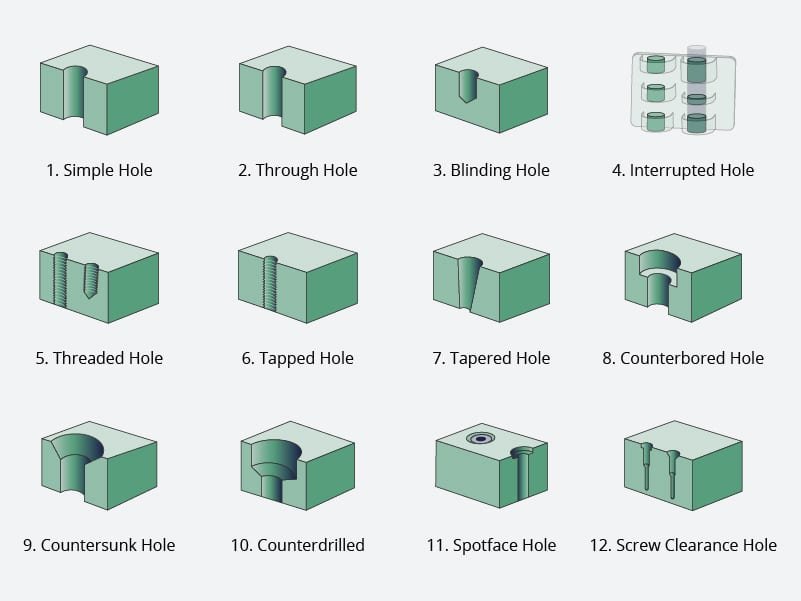

Holes in engineering enable the insertion of fasteners, facilitate the flow of liquids or gases,