Short shot injection molding (underfilling, lack of material) refers to the molten plastic in the injection not completely filling the mold cavity, that is, the product is not completed and lacks material.

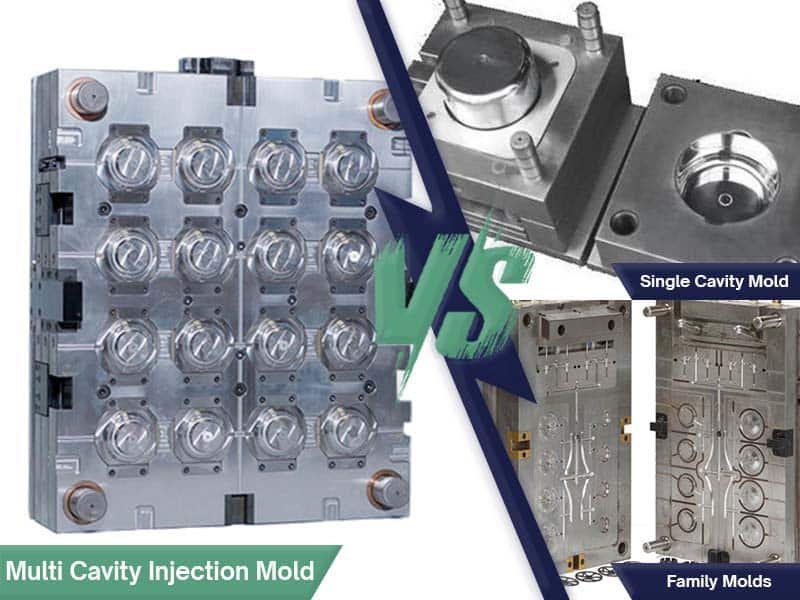

The lack of material often occurs at the end of material flow or a part of a molded product with multiple cavities is underfilled, especially in the thin-wall area, thin rib, deep rib, or the end area of the flow path. Short shot is a defect that often occurs in large-part injection molding for products with multiple ribs or ultra-thin parts. In general, short-shot injection molding is a minor defect.

Inappropriate Product Design

The wall thickness and part length are not proportionally designed will cause incomplete material flow to the end of the product. The injection molded part has a complex shape with numerous deep rib features, this can result in significant injection pressure loss and a higher risk of air trapping.

When designing the injection molded part, engineers should pay attention to the wall thickness of the part and the ultimate flow length of the resin. In the injection molding process, the thickness of the part is usually 1~3mm, and 3~6mm for large parts.

Read this guide on Thin Wall Injection Molding Design Guide.

Choosing Wrong Material

Inappropriate material will influence the process. Material with poor flowability or the material containing impurities that lead to cold slugs blocking the mold runner will lead to short shot injection molding troubleshooting.

Selecting a different polymer or adding flow-enhancing additives can improve the flowability of the injection molding material.

Additionally, regular maintenance such as cleaning the injection nozzle and modifying the mold by enlarging the cold slug well and increasing the cross-sectional areas of the runners and gates can help reduce the occurrence of injection molding defects.

Improper Gating System

If the runners or gates are too small or too long, they can create excessive resistance, causing a significant pressure drop and preventing the material from reaching the extremities of the cavity. An inadequate gating system can also cause premature cooling of the melt, increasing its viscosity and impeding its ability to fill the mold.

When designing the injection mold system, it’s important to ensure balanced gating. This means the gates should be designed to allow even flow.

Read this guide: Injection Molding Gate: Types, Locations, and Best Practices

If there’s too much pressure loss in the gate or runner, it can block the flow. This can be solved by enlarging the cross-sectional area of the runner and gate, making them wider to reduce resistance, or using multiple gates to distribute the flow more evenly.

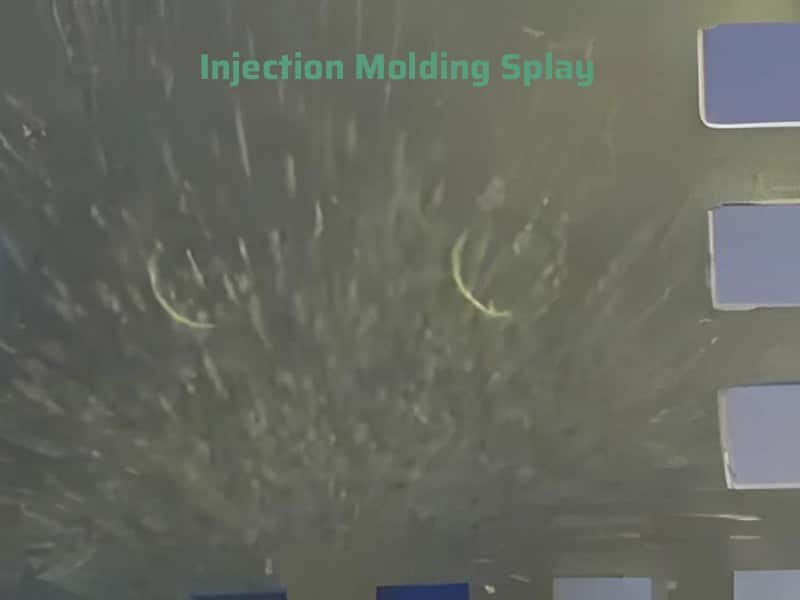

Poor Mold Venting System

A poor mold venting system can trap air within the mold cavity. When molten plastic is injected, trapped air creates back pressure, preventing the plastic from fully filling the mold. The air acts as a barrier then blocks the plastic flow and leads to short shot in injection molding.

Adding vent channels or vents allows the trapped gases to escape as the plastic fills the mold, reducing pressure and ensuring the plastic can flow freely.

Low Mold Temperature

When the mold is too cold, the plastic cools too rapidly upon contact with the mold surface. This increased rate of solidification restricts the flow of the plastic, preventing it from reaching the extremities of the mold cavity and leading to a lack of material.

When designing an injection mold, it is vital to include a good system to control the mold’s temperature. This helps keep the mold at the right temperature so the molten plastic can flow and fill every part of the mold before it cools down. Otherwise, when the molten plastic enters the mold, the mold’s temperature might not stay steady.

Low Melt and Nozzle Temperature

Insufficient melt and nozzle temperature prematurely solidifies the plastic before it fully fills the mold cavity. When the melt temperature is too low, the plastic’s viscosity increases, making it difficult to flow through the runners and gates. Similarly, a low nozzle temperature causes the plastic to cool rapidly as it exits the nozzle, further impeding its flow into the mold. This combination of factors restricts the plastic’s ability to reach the extremities of the mold.

Increasing the temperature of the molten plastic and the nozzle can help the resin flow better and fill the mold fully. However, if you make the temperature too high, the plastic can burn or carbonize. So it is important to find the right balance.

Insufficient Pressure During the Process

Insufficient injection or holding pressure during the injection molding directly leads to short shot. Without adequate pressure, the molten plastic cannot overcome the flow resistance within the mold, especially in thin sections or at the extremities of the parts.

Increase the injection and holding pressure or extend the holding time based on the actual product.

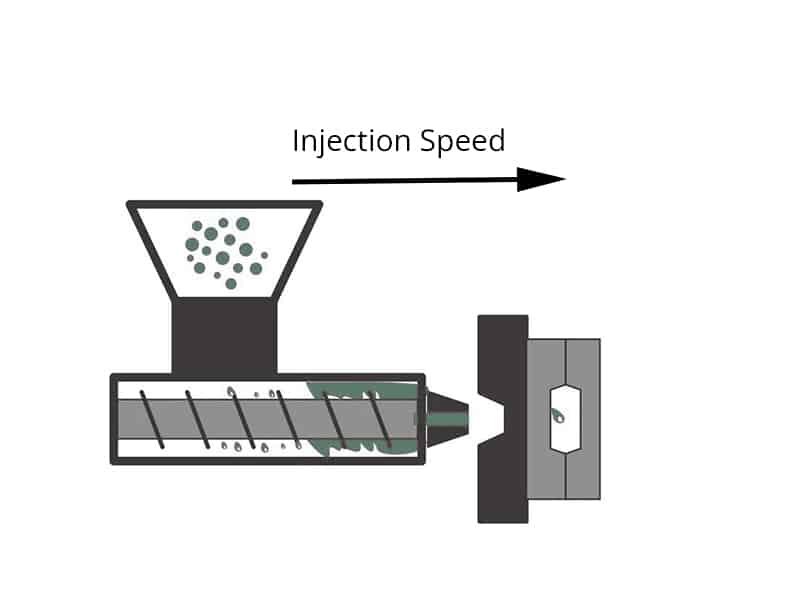

Slow Injection Speed or Insufficient Injection Time

If the injection speed is too slow, the molten plastic fills slowly, and the low-speed flowing resin cools down easily, causing a lack of material in its flow properties to produce under-injection. Increase the injection speed to keep the plastic flowing and prevent cooling.

Short injection time causes the mold not to fill completely before the machine stops injection. Extending the injection time ensures enough plastic is delivered and has time to distribute, filling the mold fully before solidifying.

Improper Injection Molding Equipment

Improper selection of injection molding equipment can result in insufficient injection pressure, leading to short-shot defects. When choosing an injection molding machine, the total injection weight of a single mold must not exceed 80% of the machine’s plasticizing capacity.

Worn Check Ring and Barrel

When the check ring of the injection screw and the barrel experience significant wear, resulting in a larger gap, the molten material can severely backflow within the barrel. This backflow can cause insufficient material supply, leading to short-shot defects. Therefore, injection molding manufacturers need to adjust the clearance between the barrel, the injection screw, and the check ring, and repair the equipment accordingly.

How to Fix Short Shot Injection Molding

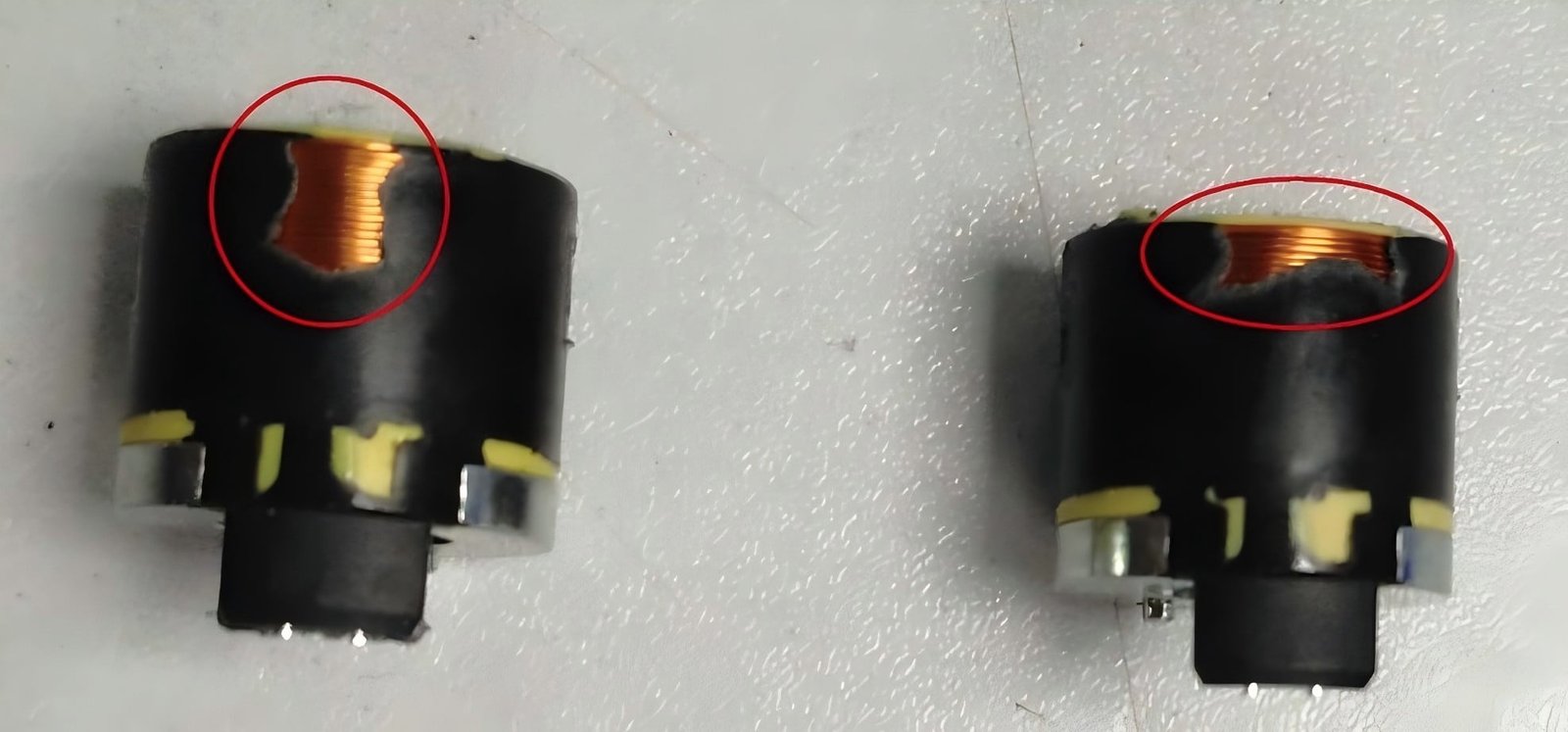

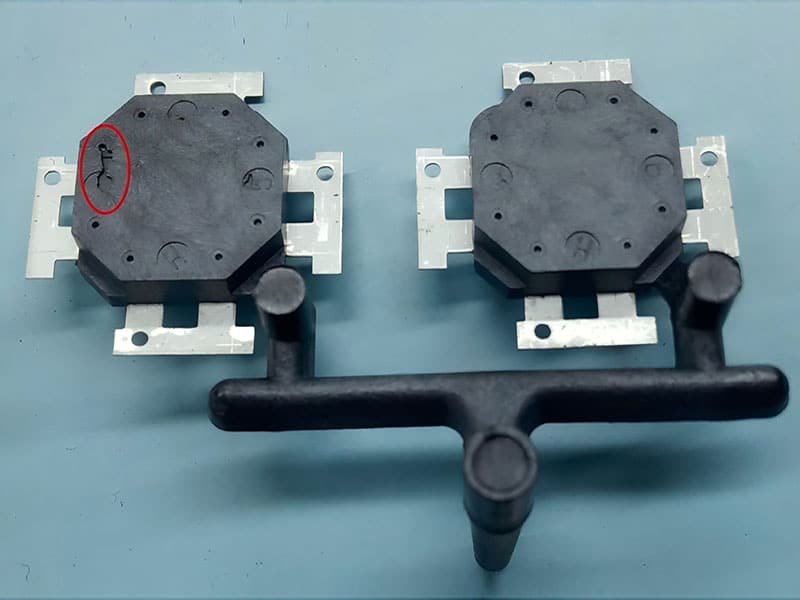

Here is a practical case study conducted by Erye engineer team to fix short shot defect in injection molding.

Project Introduction

The picture is a case of injection molding short shot. The resin is LCP (liquid crystal polymer), and the bottom plane is the thinnest part, with a wall thickness of 0.2 mm. The product’s overall dimension is 11 mm x 11 mm x 3 mm. The mold employs a direct gate and uses a side feeding method. Due to the specialty of the product structure, only low-pressure, low-speed injection molding can be used during the molding process.

Injection Molding Parameters are as follows:

| Parameter | Value |

|---|---|

| Mold Temperature | 100~120℃ |

| Material Temperature | 300~330℃ |

| Injection Speed | First Stage 80mm/s; Seconde Stage 50mm/s |

| Injection Pressure | 800kgf/cm2 |

| Injection Time | 1s |

Troubleshooting

The final weld line of the product is located at the thinnest plane, resulting in short shot (lack of material) and instability.

How Do We Fix Injection Molding Short Shot

Cause Analysis

During the injection molding process, it is quite a challenge to inject material into the thinnest section of the product. The weld line of the product also appeared at the thinnest section during injection, which brought even more difficulties to the product molding. By analysis of the injection prototypes, we found that the main reason for short shot was that the gas in the mold cavity could not be rapidly expelled.

Solutions

- Add venting positions at the four corners of the mold parting surface.

- Move the direct gate feeding position towards the thin material area, so as to let the molten plastic flow to the thin area as far as possible.

- Add air venting slot to the ejector pins on the moving mold side to meet the needs of rapid molding.

- Add venting slots to the runner, ensuring a small flash (burr) appears at the end of the runner to ensure that gases within the runner are fully expelled from the mold through the venting on the runners.

Conclusion

Short shot in injection molding is a common molding defect. This article aims to provide a comprehensive understanding of causes and solutions. If you encounter any short shot issues in your injection molding operations or have any realted technical inquiries, please do not hesitate to contact us for expert solutions.