Burn marks in injection moulding appear as dark or black discolorations, often at the end of the flow path. When these burn marks show signs of carbonization, the product is considered unqualified. Burn mark defects are considered minor appearance defects; in cases where there is only slight yellowing or minor black spots, it can be determined whether the product can be used based on the usage environment.

If the burn mark appears on the injection molding parts, first use high-speed injection to confirm whether the product will exhibit more severe burn marks. If so, it can be determined that the mold’s venting system is poorly designed and the venting effect is poor. To completely solve this, it is necessary to add more venting and adjust the position and size of the mold’s gate. Adjusting the injection speed only reduces the possibility of injection molding burn marks, but cannot completely solve them.

The causes of burn marks are primarily related to the mold and the injection molding process; below, we will analyze these aspects.

Issue with Mold Design

Burn marks in injection moulding parts can be caused by trapped air in the mold cavities. This air is unable to escape at the end of the flow path due to poor mold venting. The trapped air within the mold cavity compresses during injection, generating high temperatures and resulting in burn marks on the finished product.

To prevent burn marks, proper mold design is essential. First, incorporating effective venting systems allows trapped air to escape, reducing the risk of overheating. Additionally, adjusting the gate location, such as placing it closer to the end of the fill or using multiple gates, can optimize the flow path. Enlarging the gate size can help direct the plastic flow more evenly, minimizing pressure and temperature spikes that lead to burn marks.

Issue with Injection Speed

Injection molding burn marks occur when the injection speed is too high during molding, particularly at the end of the process. This rapid speed compresses trapped air inside the mold, leading to overheating and ignition, which scorches the plastic and leaves carbon residue.

Reducing the injection speed, especially in the final stages of filling, is a practical solution. It allows trapped air enough time to escape, minimizing the risk of compression and overheating. For thin-walled products, which are particularly susceptible to this defect due to their limited thickness and potential for restricted airflow, using cavity vacuum devices can help ensure gas is effectively removed.

Issue with Machine and Molding Conditions

Excessively high barrel or mold temperatures often cause the plastic to degrade and form dark, charred areas on the part. This degradation happens when the heat is too intense, leading to discoloration and potential structural weaknesses.

First, reduce the processing and mold temperatures to the optimal levels specified for the material, as overheating can lead to material breakdown and discoloration. Adjusting the injection pressure and speed can help control heat buildup during the molding process, preventing further degradation. Moreover, relocating or redesigning the injection gates can enhance the flow path, reducing the likelihood of air entrapment and subsequent burn marks.

Key Takeaways to Fix Burn Marks

We have analyzed that burn marks are primarily caused by trapped air that becomes compressed and overheated during the injection process. The following are the summarized key ways to prevent burn marks.

- Incorporate sufficient venting channels, especially at the end of the flow path, to allow air to escape.

- Slow down injection speed, particularly towards the end, to reduce air compression and overheating.

- Keep barrel and mold temperatures within the recommended range to prevent material degradation.

- Lower injection pressure to minimize shear heating and control heat buildup.

- Choose appropriate gate locations and sizes for even flow and reduced air entrapment.

- For thin-walled products, employ cavity vacuum devices to enhance gas removal.

Case Study-How to Get Rid of Burn Marks on Plastic

The following is a practical case study conducted by the Erye engineer team, which explains in detail how we get rid of burn marks on plastic.

Project Introduction

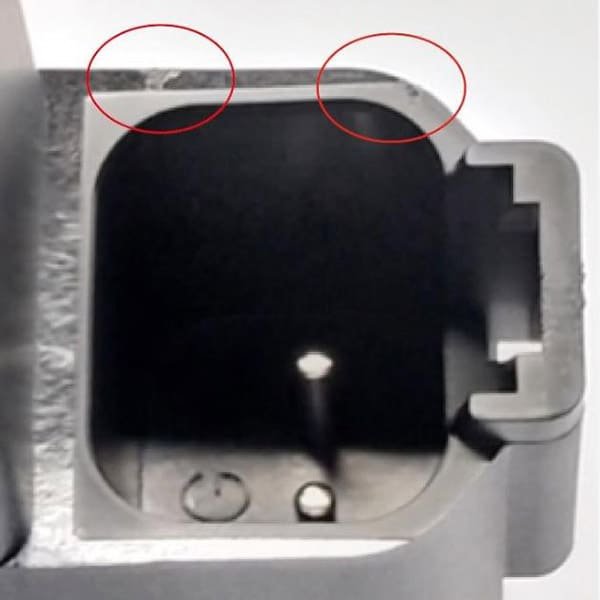

The picture is a plastic burn mark example. The product is a type of connector in PBT material with a thick wall thickness; the surface is sub-exterior. Our customer has strict quality standards, so it is allowed to have an appearance defect.

The following is the molding condition,

| Parameter | Value |

|---|---|

| Mold Temperature | 60~80℃ |

| Material Temperature | 240~260℃ |

| Injection Speed | First stage: 180mm/s; Seconde stage: 135 mm/s; Third stage: 40mm/s |

| Injection Pressure | 1300~1500kgf/cm2 |

| Injection Time | 1.5~3s |

Troubleshooting

Here is an enlarged picture of the burn mark defect section. This defect is not accepted by our customer.

How Do We Fix Burn Marks on Plastic Parts

Cause Analysis

During the initial trial molding process, our engineer analyzed the runner plate and discovered that the burn marks on the plastic are located at the weld line at the end of the product. Our further analysis concluded that the air is unable to vent from the mold cavity, resulting in trapped air and burn.

Solutions

At this stage, our client has confirmed both the product and mold structure, and cannot be changed. To address the burn mark issue, engineers can only make adjustments in terms of mold venting and the injection molding process. Our engineers implemented the following solutions:

- Enlarged the venting slots in the mold runner, parting line, and ejector pin areas as much as possible to reduce the end venting amount, thereby eliminating the burn marks on plastic.

- Adjusted the injection molding process to multi-stage injection. Due to the product’s thick wall thickness, the last two stages of injection were performed at low or even lower speeds to reduce burn marks.

By combining the above two methods, we effectively improved the burn marks and met the client’s high-quality requirements.

Conclusion

Burn marks are a common injection molding defect. There are many factors that can cause plastic defects, they can be effectively solved by eliminating them parameter by parameter. If you have trouble with burn mark troubleshooting, our experts at Erye Molding are willing to help. Contact us today for help!