What is the Meaning of Warpage

Plastic warpage deformation, often seen as twisting or distortion, happens during injection molding when the material inside the mold faces high pressure. This pressure generates internal stress, causing the final product to deviate from its intended shape and the mold’s cavity design when demolding. This can result in significant dimensional differences, known as warpage, and irregular bending.

Warpage in injection molding is inevitable, but can be minor or severe. So, how to define warpage? If it’s less than 0.05 mm, it’s usually within an acceptable range, fitting within fine tolerance standards for many materials, like ABS or PMMA, especially for smaller features. However, if it affects how parts fit together or leaves visible gaps after assembly, and impacts appearance, it requires evaluation based on specific conditions to determine if it’s a serious or minor plastic warpage defect.

Generally speaking, there are several causes of injection molding warpage, including:

- Material Selection

- Product Design

- Mold Design

- Injection Molding Process

Select Wrong Material

Warping and deformation in injection molding can occur due to several factors. Excessive moisture in the material, such as when dehumidification and drying are incomplete, can lead to issues. Incorrectly estimating the plastic’s shrinkage or the mold’s shrinkage allowance, choosing materials with poor flowability, and using improper proportions of additives or fillers are also common causes.

To solve these problems, it’s essential to check the plastic’s dryness and moisture content to ensure it’s properly prepared. Secondly, a thorough assessment of the plastic’s molding shrinkage rate should be conducted, comparing the supplier’s suggested values with actual shrinkage measurements. Applying mold compensation, which involves designing the mold to counteract expected shrinkage and warpage, is another effective strategy. Additionally, selecting high-quality, high-strength materials is crucial, especially noting that lower-density plastics tend to have greater shrinkage deformation. Finally, careful adjustment of the material’s additive ratios can optimize its properties and minimize warping tendencies.

Inadequate Product Design

Inadequate product structural design can lead to plastic warpage, particularly significant variations in wall thickness and excessively complex part geometries. If the product’s design has big differences in wall thickness, it can cool unevenly, leading to warping. Similarly, if the product’s shape is very complex, it can make it harder for the plastic to cool evenly, causing the same problem.

Changing the design to make wall thickness more consistent, ensuring it can handle the forces that cause deformation. Another option is to design the product with pre-deformation correction, which means shaping the mold to counteract expected warping. Early collaboration with experienced injection molding manufacturers during the design phase to minimize warping.

Inappropriate Mold Design and Setting

Low Mold Temperature

A substantial temperature difference between the front and rear molds, or excessively low mold temperatures, can induce uneven cooling and shrinkage, leading to plastic part deformation.

To solve the problem, it’s essential to minimize the temperature differential between the front and rear molds, ensuring a more uniform cooling process. Additionally, the mold temperature should be maintained within the material’s recommended processing range, as specified by the material supplier.

Improper Gate Placement

Inappropriate gate count or positioning in injection molds directly influences warping in finished parts. Poor gate design can lead to imbalanced flow fronts and uneven pressure distribution within the mold cavity. This results in differential shrinkage and the development of internal stresses, ultimately causing the part to warp.

Use mold flow analysis to evaluate the product’s filling dynamics and confirm the validity of the gate locations. Optimizing gate placement based on this analysis ensures a more uniform fill.

Restricted Gate and Runner Size

Gate sizes and extended runner lengths impede the flow of molten plastic, leading to uneven fill patterns and pressure imbalances within the mold cavity. This disparity in pressure and flow results in differential shrinkage during cooling, generating internal stresses that ultimately cause the part to warp.

By modifying the flow path, increasing the size of the runners allows for a more unrestricted flow of material, ensuring even distribution throughout the mold. Alternatively, reducing the number of cavities can also improve flow dynamics by lessening the demand on the existing runner system.

Uneven Ejection

Inconsistent ejection forces or speeds can create localized stresses, causing the part to deform. Similarly, if a part is ejected before it has fully solidified and cooled, it is more susceptible to warping due to residual thermal stresses. Moreover, poorly positioned ejector pins can apply uneven pressure, leading to distortion.

The solution is to design the ejection system with careful consideration of ejector pin placement and force distribution. Ensuring that the part is sufficiently cooled before ejection and that the ejection process is consistent and uniform across the part’s surface。

Inefficient Cooling Channel

Inadequate design of cooling water channels leads to non-uniform cooling efficiency. Variations in cooling rates across the mold cavity induce differential shrinkage and internal stresses, resulting in part deformation.

A well-designed cooling system ensures consistent and uniform cooling across the mold, minimizing temperature gradients and promoting even shrinkage. This uniformity reduces internal stresses, thereby minimizing the risk of warping.

Inappropriate Process Parameter

Low Barrel Temperature

When the barrel temperature is too low, the molten plastic has a reduced melt temperature, resulting in increased residual shear stress within the molded component. This elevated shear stress contributes to uneven shrinkage and internal stresses, ultimately causing the part to warp.

To effectively address this issue, it is imperative to increase the barrel temperature, reduce residual shear stress, and promote more uniform shrinkage.

Low Nozzle Temperature

When the nozzle temperature is too low, excessive heat is drawn away at the contact point between the nozzle and the mold. This causes a drop in melt temperature, and when high-speed molding is attempted under these conditions, it results in high residual shear stress within the molded part, contributing to warping.

The solution is to increase the nozzle temperature. Raising the nozzle temperature ensures that the melt maintains its optimal processing temperature, reducing residual shear stress and promoting more uniform shrinkage.

High Injection Pressure

When the injection pressure is too high, it leads to overpacking of the mold cavity, resulting in increased residual stress within the molded part. This elevated stress can cause uneven shrinkage and deformation, ultimately leading to warping.

It is recommended to reduce the injection pressure. Lowering the injection pressure helps to minimize residual stress, promoting more uniform shrinkage.

Inadequate Residence Time??

Insufficient residence time, often referred to as dwell time, means the molten plastic is not held at the processing temperature for a long enough duration, leading to incomplete melting or inadequate homogenization of the material. This results in variations in viscosity and molecular orientation, leading to uneven shrinkage and internal stresses that cause warping.

It is necessary to increase the residence time. Extending the residence time ensures that the plastic melt is thoroughly heated and homogenized, promoting more uniform shrinkage and reducing internal stresses.

Improper Flow Rate

If the flow rate is too slow, the molten plastic may begin to solidify prematurely before fully filling the mold cavity, resulting in uneven density and shrinkage. Conversely, an excessively high flow rate can lead to shear heating and increased residual stresses, also lead to warping.

A moderate and consistent flow rate ensures that the mold cavity is filled completely and uniformly, minimizing variations in density and shrinkage.

Case Study – How to Control Warpage in Plastic Parts

Here is a practical case study conducted by the Erye engineering team to control warpage in plastic parts.

Project Introduction

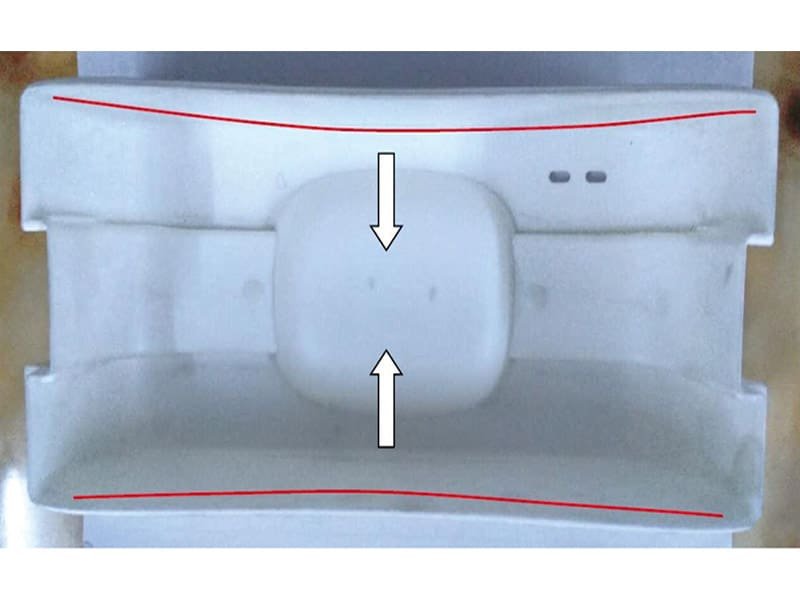

The image illustrates a case study of a plastic product warpage deformation. The product is a small appliance housing component. Below is the basic product information:

- Overall dimensions: 50mm x 25mm x 15mm

- Wall thickness: 1.5mm

- Material: PP

- Gate type: Pin gate

- Mold gate size: 1mm x 2mm

Plastic Warpage Troubleshooting

As indicated in the provided figure, the long side of 50mm has a warpage deformation to the inside. This is a common defect in injection molding, particularly for thin-walled products.

How to Control Warpage in Plastic Parts

Cause Analysis

- Product Design: The product has a relatively simple structure. Part warpage could have been mitigated if taken into account for potential inner side deformation at the design stage.

- Material: The chosen material is PP (polypropylene), which has high shrinkage, easily lead to warpage. Changing to ABS (acrylonitrile butadiene styrene) could significantly reduce this issue as it has a lower shrinkage rate.

- Injection Molding Process: High temperatures in the middle mold core can cause inner side warpage; the molding cycle time is short, and the product demolds before completely cooling down, which can result in deformation after ejection.

Solutions

Based on the cause analysis, we have several potential solutions:

- Product Design: Optimize the part design, designing the outward precession shrinkage to correct the inward contraction shrinkage

- Material: Change the material, such as ABS

- Injection Molding Process: Lower the middle mold core temperature during the injection molding process, improve the outer edges temperature, and extend the cooling time.

However, in this case, the customer chose PP material due to cost considerations, so changing the material is not an option.

During the design stage, it is difficult for designers to predict how much outward distortion should be added to correct the warpage, as it will cause other problems if not designed well.

Ultimately, our engineers decided to fix the warpage by extending the cooling time during the injection molding process. Longer cooling time leads to lower production output, which increases our manufacturing costs. Besides, it is also important to take into account the production output. Our team aims to minimize cooling time without compromising the quality, and uses correction fixtures (toolings that hold the part in shape) to ensure the final part meets the quality standard.

Plastic Injection Molding Company

Erye Molding specializes in engineered resins. We pride ourselves on our wide range of custom molding services, including molding tooling production, prototyping, manufacturing, assembling, and testing.

Struggling with plastic warpage? Our team at Erye Molding can provide expert assistance. Get in touch with our expert today!