Living hinges design is among the most effective features in plastic design. They allow two rigid sections of a part to flex repeatedly without separate hardware, reducing cost and simplifying manufacturing. Found in packaging, medical devices, consumer goods, and electronics, living hinges combine functionality with durability.

While their form is simple, their success relies on careful engineering. The right choice of material, precise geometry, and controlled molding practices determine whether a hinge lasts for millions of cycles or fails prematurely. This guide explores the fundamentals of hinge design, from hinge types to design considerations, applications, and best practices.

What is a Living Hinge

A living hinge is a thin, flexible strip of plastic that connects two thicker, rigid parts. As the hinge bends, one side stretches while the other compresses. If properly designed, the material can sustain this cycle repeatedly without cracking.

Most living hinges are injection molded, typically in polypropylene, which provides the best balance of flexibility and fatigue resistance.

Types of Living Hinges

Living hinges can take several forms, each suited to specific applications:

- Straight hinge: the most common, a simple, flexible strip used in caps and lids.

- Butterfly hinge: allows wider angles of rotation and often provides smoother opening.

- Double hinge: uses two parallel hinges for extended or fold-flat movement.

- Bi-stable hinge: designed to snap between two positions, offering tactile feedback.

These types expand design options, allowing engineers to tailor hinge function to product requirements.

Advantages and Limitations of Using Plastic Living Hinge

Advantages of Plastic Living Hinge

- Cost efficiency: no pins, screws, or assembly needed.

- High durability: properly designed hinges can last millions of cycles.

- Compact, lightweight, and integrated design.

- Aesthetic improvement: no visible hardware.

Limitations of Plastic Living Hinge

- Suitable for limited materials, mainly polypropylene.

- Cannot handle high loads or torque.

- Environmental sensitivity: UV, chemicals, and temperature can degrade performance.

- Risk of premature fatigue if poorly designed or molded.

Key Considerations of Living Hinge Design

Designing a living hinge that performs reliably over its lifetime requires attention to several interconnected factors. Material alone does not guarantee success; the geometry must be proportioned correctly, the molding process carefully managed, and stress concentrations eliminated. Environmental influences such as sunlight, chemicals, and temperature also play a decisive role, while thorough testing ensures that the hinge performs as intended in real-world conditions. Each of these elements must be considered together, as neglecting even one can shorten hinge life dramatically.

Material selection

The choice of material has the greatest influence on hinge life. Polypropylene is the most widely used resin because of its excellent fatigue resistance and ability to flex repeatedly without cracking. Homopolymer grades provide the longest service life, while copolymer grades offer higher impact resistance but at the cost of reduced hinge cycles. Read our guidelines for polypropylene injection molding.

Polyethylene can also be used, but is generally less durable, making it better suited for applications where extreme flexibility is not required. Designers should avoid using fillers such as glass fibers or mineral reinforcements, as these reduce flexibility and cause early hinge failure. For outdoor products, UV-stabilized polypropylene is recommended to resist degradation from sunlight.

Geometry

Geometry defines how a hinge behaves under repeated flexing. The thickness of the hinge web is critical: too thin and it will crack; too thick and it will resist bending. An optimal range lies between 0.18 mm and 0.38 mm (0.007–0.015 in).

Radii are equally important. A small radius of about 0.76 mm (0.030 in) on the tensile side helps reduce stress concentration. Sharp corners should be avoided altogether. To guide bending, shoulders or recesses can be added so that flexing occurs only in the hinge region. For wider lids or covers, splitting the hinge into multiple shorter segments helps distribute stress evenly and prevents fatigue in the center.

Mold design

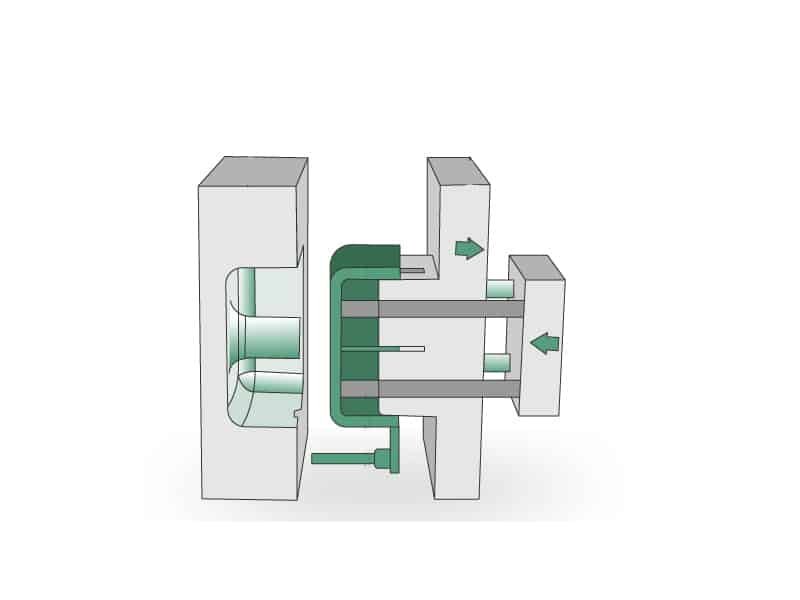

The injection mold design directly impacts hinge durability. Gates should be placed so that polymer flow runs across the hinge line, aligning the molecules in the same direction as the bending action. This molecular orientation strengthens the hinge significantly.

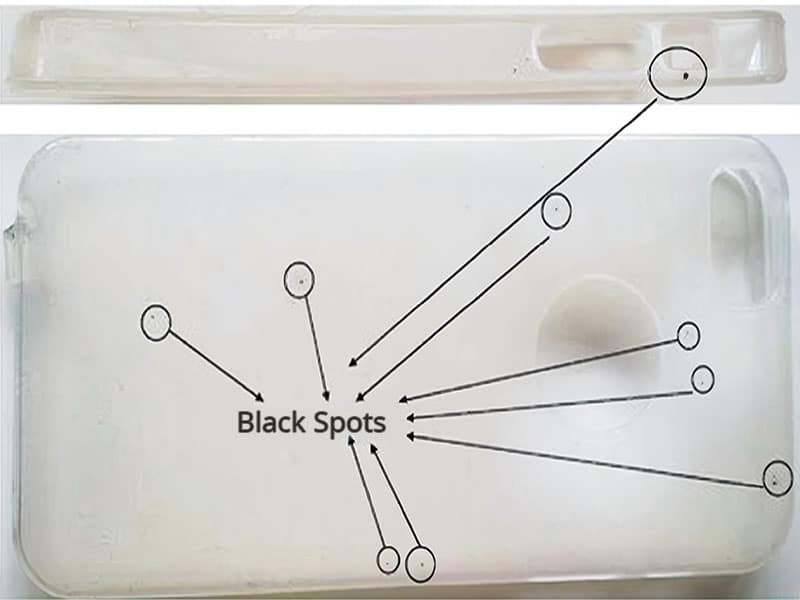

Weld lines or knit lines must be avoided in the hinge area, as they are weak spots where cracks easily form. After molding, cold drawing—flexing the hinge while the material is still warm—further improves molecular alignment and increases fatigue resistance.

Stress management

Hinges often fail due to stress concentration. The transition between the rigid part and the hinge should be gradual and smooth. Fillets and rounded transitions are effective ways to minimize stress buildup.

Long or wide hinges should not be designed as a single continuous strip. Instead, they should be divided into smaller hinge segments so that stress is spread across multiple zones, preventing localized failure.

Environmental considerations

Living hinges must be designed with their operating environment in mind. Polypropylene performs well in most indoor applications, but UV radiation can degrade it outdoors unless a stabilized grade is used. Oils, detergents, and solvents also affect hinge performance and may cause material weakening over time.

Temperature is another factor. At very low temperatures, polypropylene becomes brittle and prone to cracking. At elevated temperatures, the material is susceptible to creep, which reduces its ability to recover after flexing. Accounting for these factors during design ensures reliable long-term performance.

Prototyping and testing

Even when design follows established guidelines, validation through testing remains essential. Prototypes can be produced using short-run tooling to check hinge flexibility and strength. Cycle testing, where the hinge is repeatedly opened and closed, provides real insight into service life.

Cold drawing immediately after molding should also be part of the process, as it enhances durability. While simulation tools can help predict stress distribution, physical testing is the only way to fully confirm hinge reliability.

Plastic Living Hinge Checklist of Best Practices

- Use polypropylene (homopolymer preferred); avoid fillers.

- Keep hinge thickness between 0.18–0.38 mm.

- Provide a tensile-side radius of about 0.76 mm.

- Position gates so flow runs across the hinge line.

- Avoid weld lines in the hinge region.

- Perform cold drawing immediately after molding.

- Use smooth transitions and fillets to reduce stress.

- Segment wide or long hinges into multiple smaller ones.

- Select stabilized grades for exposure to UV, chemicals, or temperature extremes.

Applications of Plastic Living Hinge

Living hinges should not be used for safety-critical or high-load applications. Here are some commonly used applications:

- Consumer packaging: flip caps, condiment lids, and clamshell containers.

- Medical devices: pill organizers, sterile containers, disposable housings.

- Consumer goods: storage boxes, protective covers.

- Electronics: battery doors, connector flaps, protective lids.

- Automotive: lightweight glovebox lids, covers, enclosures.

Conclusion

Living hinges are efficient, reliable, and cost-effective when designed properly. Their success depends on selecting polypropylene, controlling geometry, optimizing molding, and managing stress. Environmental conditions and testing further ensure long-term durability.

By following these guidelines, engineers can design hinges that achieve millions of cycles, extending their usefulness across industries ranging from packaging to automotive.