Injection molding is a process that transforms raw materials into precisely engineered plastic components. Injection mold runner system is central to this process – a channel network responsible for guiding molten plastic from the injection unit to the mold cavity. Mold runners are designed to ensure efficient and even distribution of the molten material. The runner system influences every aspect of the injection molding process, from production speed to material efficiency and product quality.

In injection molding, hot runner and cold runner systems are two main types of runner systems that represent two distinct approaches to transferring molten plastic into mold cavities. The key difference between hot runner and cold runner is that the former excels in high-volume production with stringent quality requirements, while the latter offers flexibility and lower costs for smaller runs. Each system has its unique characteristics, advantages, and disadvantages, making them suitable for different applications.

What is Hot Runner Systems

Hot runner systems represent a technologically advanced approach in injection molding, designed to keep molten plastic in a fluid state as it flows through the runner system. Unlike cold runners, hot runners eliminate solidification within the channels, making them a highly efficient option for large-scale production and complex mold designs.

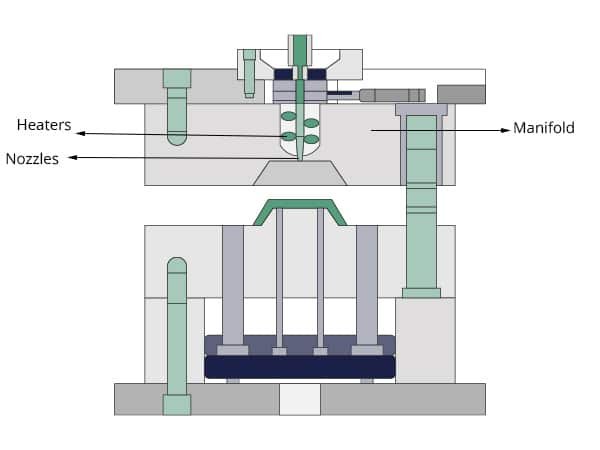

The Key Components of Hot Runner Systems:

- Manifold: A central component that evenly distributes molten plastic to multiple cavities.

- Nozzles: Direct the molten material into the individual cavities with precision.

- Heaters: Integrated elements maintain consistent temperatures throughout the system.

- Temperature Controllers: Ensure precise heat regulation to prevent material degradation or overheating.

Hot runner systems operate by channeling molten plastic through a heated manifold and nozzles. The heaters ensure the material remains in a liquid state until it enters the mold cavity, reducing material waste and enhancing product quality. This continuous flow eliminates the need for trimming or recycling solidified runners, streamlining the production process.

Advantages and Disadvantages of Hot Runner Systems

Advantages:

- Material Efficiency: Minimizes waste by keeping material in a molten state, eliminating solid runners.

- Faster Cycle Times: By maintaining consistent flow, hot runners enable quicker cooling and ejection cycles.

- Superior Part Quality: Enhanced control over material flow reduces common defects like sink marks, weld lines, and voids.

- Scalability: Ideal for high-volume production and complex injection molding runner designs.

Disadvantages:

- High Initial Cost: Requires significant investment in advanced equipment and technology.

- Complexity in Maintenance: Repairs and troubleshooting are more intricate due to the integrated heating and control systems.

- Thermal Sensitivity: Inconsistent temperature control may lead to material degradation or defective parts.

Cold Runner Systems

Cold runner systems are the traditional approach to injection molding, relying on unheated channels to guide molten plastic to the mold cavities. As the material cools and solidifies within the runner, it becomes part of the molded product and requires trimming during post-production.

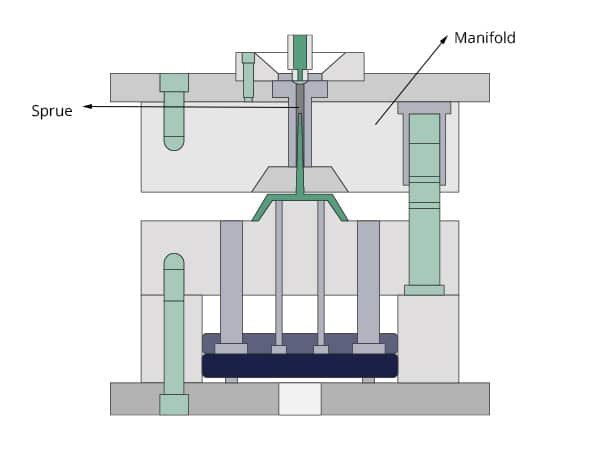

The Key Components of Cold Runner Systems:

- Sprue: The main channel through which molten plastic flows from the injection unit.

- Runners: Branching channels that guide material to the cavities.

- Gates: Narrow openings that regulate the flow of molten plastic into the mold cavity.

In cold runner systems, the molten plastic is injected into unheated runner channels, where it begins to cool and solidify as it travels toward the mold cavities. After solidification, the runners are removed and either discarded or recycled, making this system more waste-prone but simpler in design.

Advantages and Disadvantages of Cold Runner Systems

Advantages:

- Cost-Effective Setup: Lower initial investment compared to hot runner systems.

- Simplicity in Design: Easier to operate, repair, and maintain.

- Material Versatility: Compatible with a wide range of polymers, including specialized materials.

Disadvantages:

- Increased Waste: Solidified runners require post-processing, leading to higher material consumption.

- Slower Production Cycles: Cooling and solidification stages extend cycle times.

- Design Constraints: Less efficient for complex molds and multi-cavity systems.

Hot Runner vs. Cold Runner: Key Differences

Temperature Management

Hot runner systems maintain consistent heat throughout the runner mold, ensuring molten material flows uninterrupted to the cavities. Cold runner systems, by contrast, rely on ambient cooling, causing material solidification within the runners. This fundamental difference impacts production efficiency and material utilization.

Material Flow and Cooling in Both Systems

In hot runner molding, continuous material flow prevents common defects like voids and weld lines, resulting in higher-quality outputs. Cold runner molding, on the other hand, often experiences flow interruptions due to cooling, which can introduce inconsistencies or imperfections in the finished product.

Efficiency and Production Speed: Hot Runner vs. Cold Runner

Hot runners excel in large-scale production due to faster cycle times and reduced waste. Cold runners, while slower, remain a cost-effective option for low-volume production and less complex runner molding requirements.

Comparing Cost and Efficiency: Hot Runner vs. Cold Runner

Hot runner systems involve a higher upfront investment due to their complexity and the necessity of heating elements. Despite this, they typically offer lower per-part production costs in high-volume applications by eliminating runner waste and enabling faster cycle times. While hot runners may incur higher maintenance expenses due to their intricate components, the efficiency gains often justify the initial expense, especially for large-scale production. In contrast, cold runner systems generally have lower initial setup costs due to their simpler design and lack of heating elements, making them appealing for small production runs or prototyping. However, they can lead to higher long-term operational costs because they generate waste from solidified runners and often require more time for post-processing.

Hot Runner vs Cold Runner Summary Comparison

| Feature | Hot Runner | Cold Runner |

|---|---|---|

| Temperature Control | Heated channels maintain molten state | Unheated channels cool and solidify |

| Waste | Minimal (no scrap runners) | Higher (requires removal of runners) |

| Cycle Time | Faster | Slower |

| Cost | Higher initial and maintenance costs | Lower initial and maintenance costs |

| Material Compatibility | Limited for heat-sensitive polymers | More versatile |

| Color Change | More complex | Easier |

Factors to Consider When Deciding Between Hot and Cold Runners

Choosing the right runner system hinges on a range of technical, economic, and production-related factors. To make the most informed decision, consider the following elements:

- Mold Design Complexity: Hot runner systems are ideal for complex, multi-cavity molds where precision and material flow control are essential. Cold runner systems, in contrast, offer simpler designs and are better suited for less intricate molds.

- Material Flow and Handling: The type of polymer you plan to use can influence which runner system is most suitable. Materials that require precise temperature control, such as high-performance thermoplastics, often benefit from hot runner systems.

- Waste Reduction Needs: If minimizing waste is a priority, hot runners are the more favorable option, as they prevent solidification within the runner, eliminating the need for trimming. Cold runners, however, require post-processing to remove solidified runners.

- Production Scale: For large-scale, high-volume production runs, hot runners are typically the better option due to their speed and efficiency. For lower volume or prototype runs, cold runners can offer cost-effectiveness despite slower cycle times.

- Cost Evaluate Cost: For manufacturers focused on high-volume, high-quality production, hot runners deliver significant cost savings over time. Cold runner system is ideal for manufacturers on a tight budget or those who produce limited quantities of products.

Making the Right Decision for Your Injection Molding Project

The difference between hot runner and cold runner systems is a critical consideration in the injection molding process, impacting everything from production efficiency to product quality. Before making the final decision, mold manufacturers must consider the complexity of the product design, the type of material to be used, production volume, and the desired turnaround time. By considering these factors manufacturers can optimize their production workflows, reduce waste, and choose the right system for their specific needs.