The success of the injection molding process hinges on several injection molding parameter that influence the quality efficiency and consistency of the injection molded part. Parameters in injection molding refer to the specific measurable factors that govern the injection molding process. In this post, we will explore the common parameters and their importance in the injection molding process.

The fundamental parameters in injection molding are crucial for ensuring the quality, efficiency, and consistency of the molded products. Here are the key parameters that significantly influence the injection molding process:

1. Injection Pressure

Injection pressure in the injection molding process is the pressure applied by the injection machine to force molten plastic into the mold cavity. This pressure is generated by the forward movement of the injection screw or plunger, which pushes the plastic melt from the barrel into the mold through the runner system and gates. Typically measured in units like psi or bar. Injection pressure is calculated based on the projected area of the part and typically ranges from 150-350 kg/cm^2 (2100-5000 psi).

Importance of Injection Pressure

- Mold Filling: This ensures that the mold cavity fills completely, which is particularly important for parts with thin walls, intricate designs, or complex geometries. Insufficient injection pressure may result in incomplete filling, known as a “short shot.”

- Part Quality and Strength: Proper injection pressure ensures a dense, homogeneous fill, which can help avoid voids, weak points, and other structural defects.

- Dimensional Accuracy: By applying the right amount of pressure, the material flows smoothly into all areas of the mold, resulting in accurate dimensions and minimizing shrinkage-related issues.

Effects of Injection Pressure on Part Quality

High injection pressure helps fully fill the mold, reduces the chances of short shots, and enables complex parts and thin walls to be molded.

However, excessively high pressure can cause issues like flashing (where material escapes between mold halves), increased internal stress, and the risk of warping or cracking due to built-up tension within the part.

Low injection pressure reduces internal stress, lowers energy consumption, and minimizes the risk of flashing. However, insufficient pressure may lead to incomplete filling, leaving voids, short shots, or poor surface quality, especially in parts with intricate details or thin walls.

How to Optimize Injection Pressure?

Optimizing injection pressure in injection molding involves balancing the pressure to ensure complete cavity filling without causing defects like flash, warping, or excessive stress on the mold. Start by setting the injection pressure based on material properties, part design, and mold geometry, then use a trial-and-error approach to fine-tune it. Monitor the fill rate and adjust the pressure to achieve consistent part quality while minimizing cycle time. Utilize process monitoring tools and software to analyze pressure curves and identify optimal settings. Additionally, ensure proper venting and gate design to reduce resistance, and consider using variable pressure profiles to address complex part geometries. Regularly maintain the machine and mold to prevent pressure fluctuations and ensure consistent performance.

2. Mold Temperature

Mold Temperature in the injection molding process refers to the temperature of the mold cavity surfaces, controlled by heating or cooling channels within the mold. The mold temperature is typically regulated with water or oil flowing through these channels to maintain consistent and optimal conditions during each molding cycle. It affects the surface quality, dimensional stability and mechanical properties of the molded part.

Importance of Mold Temperature

Mold temperature directly affects how the molten plastic flows, cools, and solidifies within the mold. Proper control of mold temperature influences several critical aspects of the final product:

- Part Quality and Surface Finish: A well-regulated mold temperature helps achieve a smooth, consistent surface finish. Higher mold temperatures allow the plastic to replicate the mold’s surface more accurately, leading to better surface appearance and detail.

- Mechanical Properties: Uniform cooling can reduce internal stresses, which improves the part’s mechanical properties and reduces the risk of warping or deformation.

- Dimensional Accuracy: Consistent mold temperature helps control shrinkage, leading to better dimensional stability and accuracy.

- Cycle Time: Mold temperature also affects the cooling phase duration, influencing the cycle time. A cooler mold reduces cooling time but may impact quality.

Effects of Mold Temperature on Part Quality

Higher mold temperature improves the flow of the molten plastic, helping to fill the mold completely, which is beneficial for complex or thin-walled parts. Reduces internal stress and can improve part strength by minimizing shrinkage and reducing the likelihood of warping. Higher mold temperature improves the surface finish and appearance of the part. However, increases cycle time since the part takes longer to cool, which may reduce overall production efficiency.

Higher temperatures may cause material degradation in heat-sensitive plastics. Lower mold temperature reduces cooling and cycle times, allowing faster production. Lower energy consumption, as less heating is required. However, lower mold temperature may result in poor surface finish or increased shrinkage, especially in thicker sections or for materials with high shrink rates. Lower mold temperature can lead to defects such as sink marks, flow lines, and warping due to uneven cooling.

3. Melting Temperature

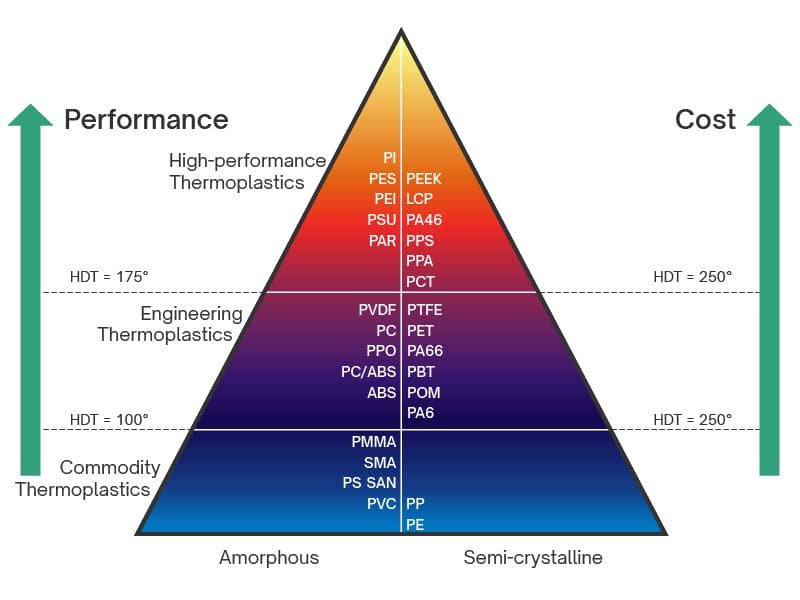

Melt temperature refers to the temperature of the polymer as it is injected through the nozzle into the mold. Achieving the correct melt temperature is essential for ensuring that the plastic flows properly and fills the mold without defects. The desired melt temperature is influenced by several factors, including the type of thermoplastic, residence time in the barrel, and the specific requirements of the final product.

Effects on Product Quality

The melt temperature affects the viscosity of the polymer. Higher temperatures typically reduce viscosity, allowing for easier flow into complex mold geometries. However, excessively high melt temperatures can lead to thermal degradation of the material, resulting in poor mechanical properties and surface defects. Conversely, lower melt temperatures can enhance certain properties such as impact resistance in materials like polypropylene.

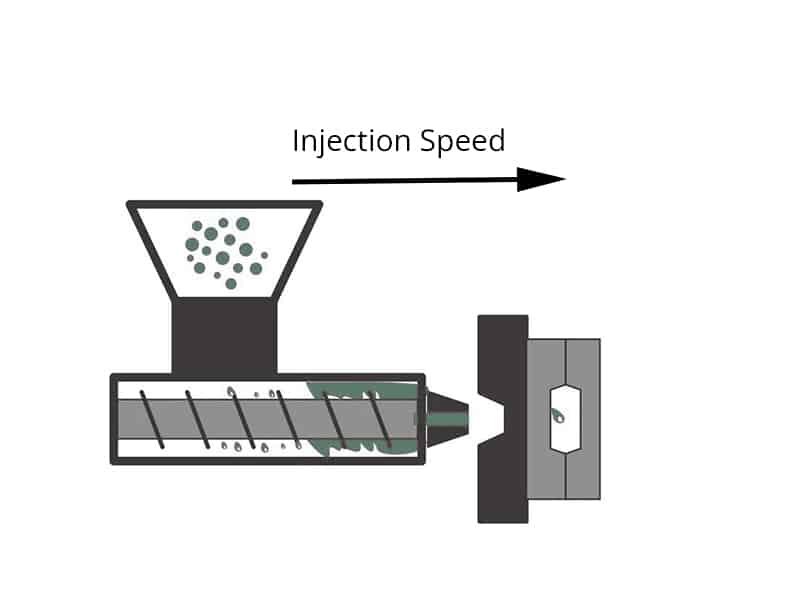

4. Injection Speed

Injection speed is a critical parameter in the injection molding process. It is the rate at which the screw or plunger moves forward, pushing molten plastic into the mold cavity. It is typically adjustable and varies depending on the material and design of the part being molded.

Injection Speed Impact on the Filling Process

The injection speed directly affects how well the molten plastic fills the mold cavity. A well-calibrated speed ensures that the mold is filled completely before the material begins to solidify. If the speed is too slow, the plastic may start to cool and solidify prematurely, leading to incomplete fills and defects.

Higher injection speeds can enhance surface quality by reducing the likelihood of defects such as flow lines and surface imperfections.

Injection Speed Influence on Material Properties

Injection speed affects the molecular orientation of polymers during filling. Higher speeds can lead to increased shear heating and molecular alignment, which can enhance the strength and durability of the final product. Conversely, slower speeds may result in lower molecular orientation and weaker parts.

The injection speed also influences shrinkage rates. Higher speeds can reduce shrinkage by minimizing cooling time during injection, while slower speeds may increase shrinkage risks due to prolonged exposure to cooler mold surfaces.

Injection Speed Influence Cycle Time Efficiency

Faster injection speeds contribute to shorter cycle times, allowing for higher production volumes.

5. Cooling Time

Cooling time is the duration the part remains in the mold after filling to allow solidification, accounting for approximately 70% to 85% of the overall cycle time. Proper cooling time prevents warpage and ensures uniform solidification. The cooling time directly impacts the overall cycle time.

Factors Influencing Cooling Time

- Part Thickness: Thicker parts require longer cooling times due to the greater volume of material that needs to solidify. Conversely, thinner parts cool more quickly.

- Material Properties: Different plastics have varying thermal conductivities and melting points, affecting their cooling rates. Materials with lower melting points generally solidify faster than those with higher melting points.

- Mold Design: The design of cooling channels within the mold plays a significant role in heat dissipation. Well-designed molds with effective cooling channels can significantly reduce cooling times and improve uniformity.

- Ambient Conditions: External factors such as ambient temperature and humidity can influence cooling efficiency.

6. Holding Pressure

Holding pressure, also known as packing pressure, is a crucial aspect of the injection molding process. It refers to the pressure applied to the molten plastic in the mold cavity after the initial injection phase, aimed at compensating for material shrinkage during cooling and ensuring the final product’s quality. Typically, holding pressure is set between 30% to 80% of the maximum injection pressure, depending on the material being used. For instance, some materials may require holding pressures around 70% to 80% of injection pressure to achieve optimal results68.

Purpose of Holding Pressure–Compensation for Shrinkage

As molten plastic cools, it tends to shrink. Holding pressure helps maintain the volume of the material in the mold cavity, preventing defects such as sink marks and voids that can arise from this shrinkage.

Effects of Holding Pressure on Product Quality

- Insufficient Holding Pressure: If holding pressure is too low, it can lead to short shots (incomplete filling), sink marks, and reduced part density. This results in lower mechanical strength and potential dimensional instability.

- Excessive Holding Pressure: If holding pressure is set too high, it can cause issues such as warping, flash (excess material at the mold’s edges), and increased residual stress within the part.

Holding Pressure Influence on Process Efficiency

Effective use of holding pressure can contribute to shorter cycle times by ensuring that parts are filled quickly and solidified properly without defects. Properly managed holding pressure helps maintain consistent product dimensions and quality across production runs. This consistency is essential for meeting customer specifications and reducing waste due to defective parts.

7. Back Pressure

Back pressure, also known as plasticizing pressure, it refers to the pressure exerted on the screw during the plasticizing phase. Back pressure is generated as molten plastic is pushed through the nozzle and into the mold. It acts against the forward motion of the screw, creating resistance that helps to control the flow and mixing of the material. This pressure is essential for achieving consistent shot sizes and maintaining uniform melt quality throughout the injection cycle. The optimal level of back pressure varies depending on the material being used. Manufacturers typically set back pressure between 500 to 1,000 psi based on material properties and processing requirements.

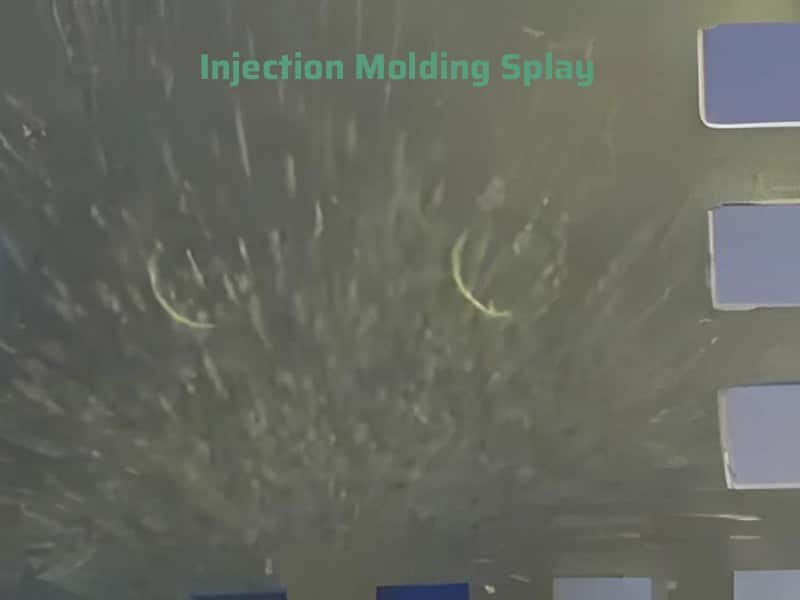

Back Pressure Effects on Product Quality

Properly managed back pressure helps mitigate shrinkage during cooling, promoting isotropic shrinkage and reducing dimensional variations in molded parts. Insufficient back pressure can lead to defects such as short shots, splay (surface imperfections), and bubbles due to trapped air. Conversely, excessive back pressure may cause issues like warping or increased residual stress within the part.

8. Clamping Force

Clamping force is the pressure applied to keep the mold closed during the injection process. It must be sufficient to withstand the injection pressure without allowing the mold to open. Proper clamping force ensures that the material packs tightly against the mold walls, which is essential for achieving desired shapes and preventing issues like air pockets or incomplete fills.

If the clamping force is insufficient, the mold can open prematurely, leading to defects such as flash (excess material escaping from the mold) and dimensional inaccuracies in the molded parts.

Calculating Clamping Force

The formula for calculating clamping force is generally expressed as:

Clamping Force N = Injection Pressure MPa × Projected Area mm²

Factors Influencing Clamping Force Calculation

- Projected Area: The size and geometry of the part being molded directly influence the required clamping force. Larger and more complex parts necessitate higher clamping forces to prevent separation during injection.

- Material Properties: Different materials exhibit varying characteristics under pressure. Harder materials like polycarbonate require greater clamping forces compared to softer materials like polyethylene, which can affect how much pressure is needed to keep the mold closed.

- Injection Pressure: The pressure at which molten plastic is injected into the mold also affects clamping force requirements. Higher injection pressures necessitate greater clamping forces to counteract potential mold separation.

- Mold Design: The design of the mold, including factors such as cavity configuration, cooling channels, and venting, plays a significant role in determining clamping force needs.

Want to have a deeper explore of clamping force? Continue read our post What is Injection Molding Clamping Force and How to Calculate?

Conclusion of Injection Molding Parameter

Understanding the fundamental parameters in injection molding process and their intricate relationship with material properties is essential for optimizing the manufacturing process. By carefully selecting materials and adjusting parameters such as temperature, pressure, speed, and cooling time, manufacturers can significantly enhance product quality while minimizing defects.