PP Polypropylene Machining Service

Get high precision and consistency machined polypropylene (PP) with strong chemical resistance and low moisture absorption.

We Offer Polypropylene Machining Services Specific to Your Needs!

PP (polypropylene) is lightweight, chemical resistance, and easy to work with. We can machined PP material from fluid-handing components to simple structural parts. It's not the toughest plastic out there, but if your application doesn't demand high strength, PP offers great value and performance.

- Rapid prototyping and low-volume production

- Tight-tolerance machining down to ±0.05mm

- Post-processing: tapping, threading, polishing

- Custom surface finishes and inserts

- Fast turnaround and responsive engineering support

What is Machined Polypropylene

Machined polypropylene is a soft, flexible thermoplastics, it is easy to machined but need careful handling to avoid string or surface roughness. Machined PP parts doesn’t need expensive tooling, it is a good choice for small batches, prototypes, or custom designs.Machined PP Grades We Work With

We work with seveal types of polypropylene that are suitable for CNC machining. Each one has slightly different properties depending on its formulation. Here are the main types we offer.- Homopolymer PP: This is commonly used for general-purpose parts, it offers slightly higher strength and stiffness.

- Copolymer PP: It is a bit softer and more impact-resistant than homopolymer. We use it for parts that need to flex without breaking.

- Glass-filled PP: The reinforced with glass fibers improves stiffness and demensional stability. We use this type to machine parts that require tighter tolerances or added strength.

- Food-grade PP: It is safe for food contact. We machine this type for clients mostly in food processing.

Types of PP Machining We Offer

Machined Polypropylene Properties

Here are the key machined polypropylene properties, the data shall change based on PP grade and the adding filler.| Item | Value |

|---|---|

| Density | 0.90 – 0.91g/cm³ |

| Tensile Strength | 30 – 40MPa |

| Flexural Modulus | 1,000 – 1,500MPa |

| Izod Impact (Notched) | 50 – 150J/m |

| Elongation at Break | 200 – 600% |

| Melting Point | 160 – 170°C |

| Water Absorption (24h) | < 0.01% |

-

Key Benefits of Polypropylene Machining

- With excellent chemical resistance, PP is resitance to wide range of acids, alkalis, and solvents.

- PP has low moisture absorption, it can resistance to water and humidity which make it suitable for outdoor or high-humidity environments

- PP is one of the lightest thermoplastics, meanwhile, it maintains impact resistance and flexibility under stress.

- It is suible for non-conductive componets as PP has high dielectric strength and excellent electrical insulating properties.

- Compared to other engineering plastics, PP has relatively low material cost.

-

Shortcomings of Polypropylene Machining

- PP has a relatively high thermal expansion rate and low stiffness, so it has poor dimensional stability for tight tolerances.

- It scratches and dents more easily than harder plastics like acetal or nylon as PP has low surface hardness.

- PP softens quickly under sustained heat, so it is not suitable for high-temperature applications.

- PP is difficult to bond or paint without surface treatment, it is not suitable for bonded featured products.

Popular PP Machined Parts

Here are some popular PP CNC machined parts we have made:- Sheets and panels

- Washers & spacers

- Pipe fittings

- Mounting brackets

- Bushings & flanges

- Structural blocks

Have a Question?

Additonal Options for Polypropylene Product

Related Polypropylene Machining Resources

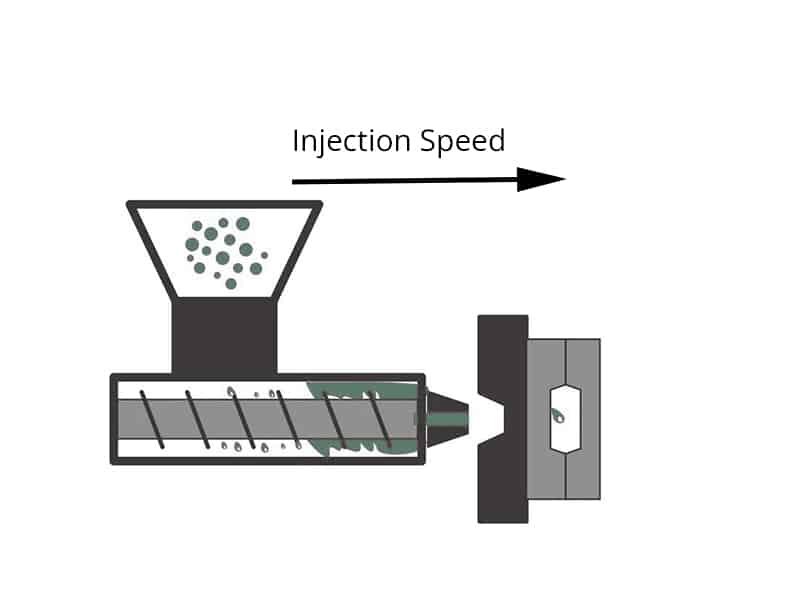

Injection speed in injection molding refers to the rate at which molten plastic is introduced

Injection molding is a versatile manufacturing process that transforms raw materials into intricate, high-volume components.

The success of the injection molding process hinges on several injection molding parameter that influence