Nylon Machining Service

We Provide Nylon Machining Services to Match Your Needs!

At Erye, we machine a wide range of nylon parts, from simple spacers, nylon pulleys to complex industrial components. Nylon is a tough, flexible material that's ideal for parts that need strength, wear resistance, and a bit of flexibility.

From DFM (Design for Manufacturability) reviews to machining setup, final inspection, and final delivery, we keep the whole process in-house for better control and faster communication, making sure each custom nylon CNC part meets your exacts specs.- Assistance with material selection and part design

- Complete fabricating and CNC machining services

- Able to machine different grades of nylon

- Size from small, intricate parts to large parts

What is Nylon(PA) CNC Machining

CNC nylon machining is the process of cutting and shaping nylon stock into precise parts using computer-controlled machines. Nylon is a strong, lightweight plastic that’s often used when you need good wear resistance and a bit of flexibility.

Because nylon can be tricky — it tends to absorb moisture and can move slightly during machining — it takes careful planning and setup to get it right. We use sharp tools, proper feeds and speeds, and well-thought-out fixturing to make sure the final parts are accurate and consistent.

Machining Nylon Grades We Work With

We machined a variety of nylon grades to match different project needs. We choose the right type depending on material strength and the using condition. Here are some of the common grades we work with:

- Nylon 6: Good toughness and wear resistance. Handles impact well and works for general-purpose parts.

- Nylon 66: Stronger and stiffer than Nylon 6. Better at holding shape under heat. Often used for structural parts.

- Nylon 12: Lower moisture absorption compared to other nylons. Good choice when you need dimensional stability.

- Glass-Filled Nylon: Reinforced with glass fibers to boost strength and stiffness. Great for high-load or high-wear parts.

- Oil-Filled Nylon: Lubricated internally to reduce friction. Ideal for bushings, bearings, and sliding parts where you want less maintenance.

Types of Nylon Machining We Offer

Machined Nylon Properties

Here are the typical material properties of machining nylon, the data shall change based on different grades.| Item | Value |

|---|---|

| Density | 1.12 – 1.15 g/cm³ |

| Tensile Strength | 70 – 90 MPa |

| Flexural Modulus | 2,400 – 3,000 MPa |

| Elongation at Break | 20% – 50% |

| Density | ~1.04 g/cm³ |

| Impact Strength (Notched) | 5 – 8 kJ/m² |

| Continuous Use Temperature | -40°C to 100°C (can handle short peaks higher) |

| Water Absorption (24h) | 1% – 2% |

| Coefficient of Friction | 0.25 – 0.35 |

-

Key Benefits of Nylon Plastic Machining

- Nylon excellent wear resistant, it can hold up to well again friction and sliding contant.

- It is high strength and light weight in weight, making it great for mechanical systems

- Nylon has good impact resistance, it can absorb shock loads without cracking, suitable for dynamic systems.

- Good chemical resistance, Nylon can withstand exposure to oils, fuels, greases, and most chemicals without breaking down.

- Nylon is easy to machine and has good dimensional stability.

-

Shortcomings of Nylon Plastic Machining

- Nylon tend to absorb water from air, it has lower dimensional stability in humid environments.

- Nylon is softens if get hotter than 100°C (212°F), not ideal for high heat applciations.

- It has surface finish limitations as it is harder to get a super fine, glossy surface on Nylon

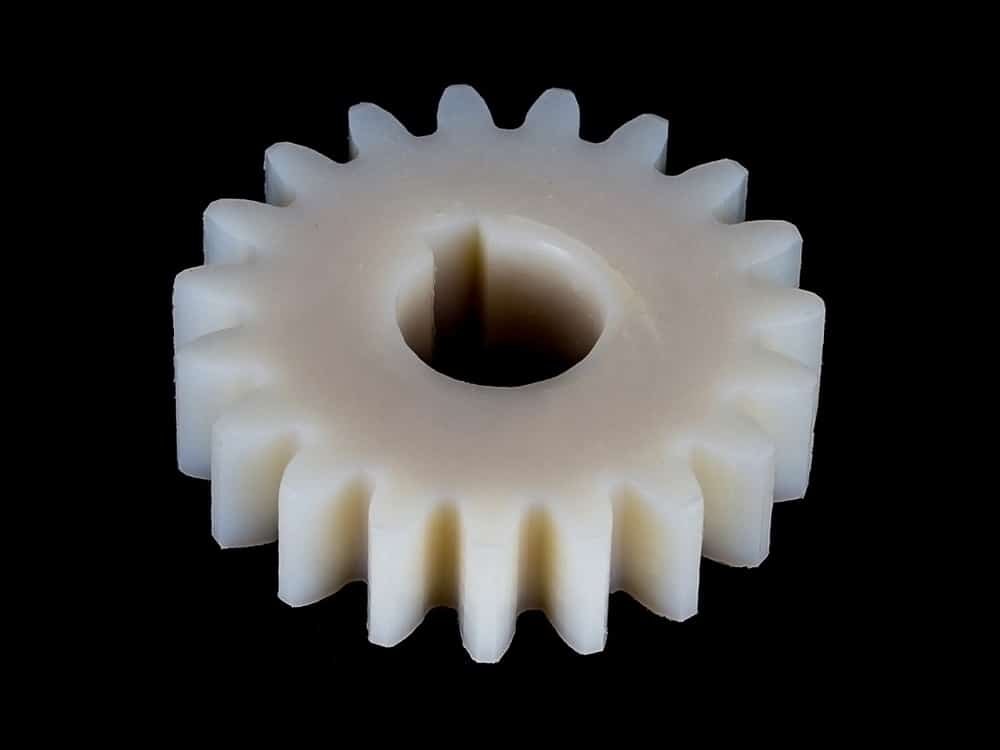

Popular Nylon Machined Part

Here are some popular Nylon machined parts we have made:

- Nylon roller

- Insulator plate

- Nylon bushing

- Nylon gear

- Pulley wheel

- Custom bracket

Have a Question?

Additonal Options for Nylon Parts

Related Nylon Machining Resources

Injection molding is a versatile manufacturing process that transforms raw materials into intricate, high-volume components.

Reaction Injection Molding (RIM), is a specialized manufacturing process tailored for producing plastic parts, particularly

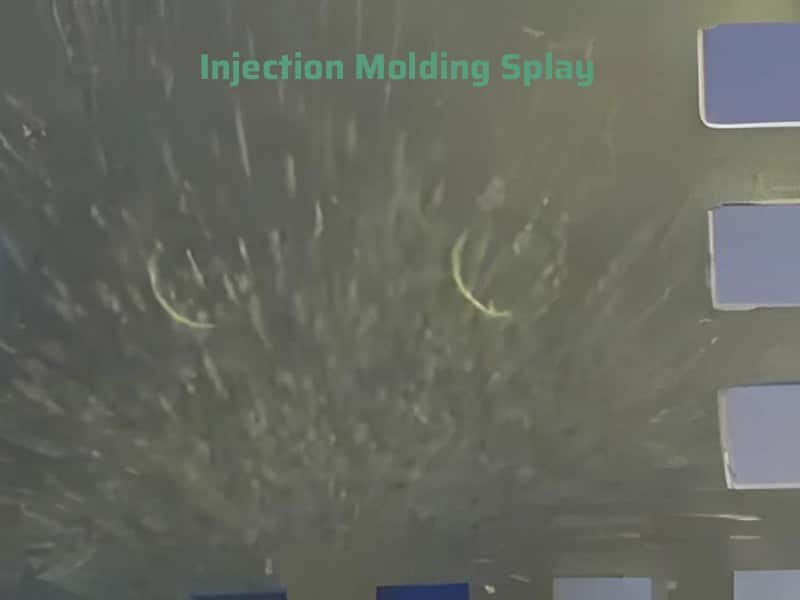

Injection molding splay is a common defect that can compromise the appearance and quality of