Nylon Casting -- Cast Nylon Part

Erye Offer Nylon Casting Service Specific to Your Needs!

Cast nylon parts are produced through a specialized monomer casting process, where liquid monomer is polymerized directly within a mold. This method allows for the creation of large, thick, and structurally sound components that would be difficult to achieve with traditional molding techniques.

We provide custom nylon casting service with high precision. Whether you need cast nylon pulleys, rollers, gears, or complex industrial components, we have the expertise and capacity to meet your need.Why Choose Us for Nylon Casting

Custom Formulations

Large & Complex Part Production

Engineering Support

Flexible Production Volumes

Advantages of Nylon Casting

Large Part Capability

Lower Tooling Costs

Excellent Mechanical Properties

Reduced Internal Stress

Chemical and Wear Resistance

Drawbacks of Nylon Casting

Slower Production Cycle

Limited Surface Finish

Part Complexity Constraints

Material Inconsistency

Start Nylon Casting Project

Application of Nylon Casting

Industrial Components

- Gears

- Bearings

- Bushings

- Wear pads

- Rollers

Heavy-Duty Applications

- Crane sheaves

- Sprockets

- Pulleys

- Chain guides

Oil & Gas Industry

- Seals

- Pipe clamps

- Insulating components

Mining

- Sheaves

- Chute liners

- Large gears

- Conveyor rollers

Additonal Options for Nylon Parts

Related Nylon Casting Resources

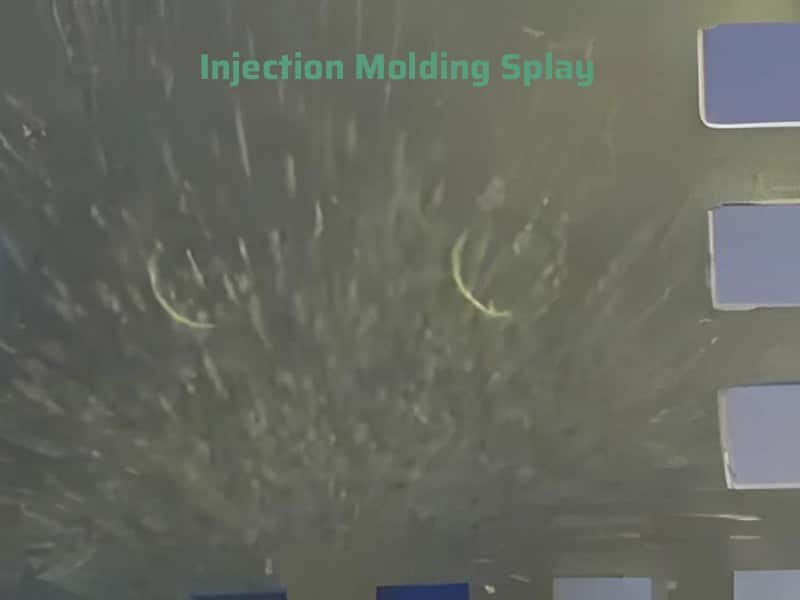

Injection molding splay is a common defect that can compromise the appearance and quality of

If you’re looking to cut down on injection molding mold costs, you’re in the right

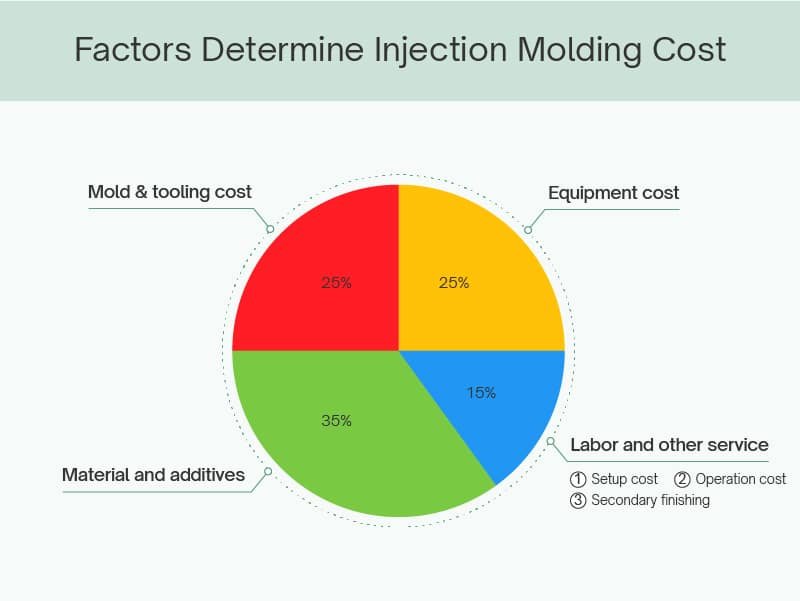

The injection molding cost varies depending on a variety of factors, such as material choice,