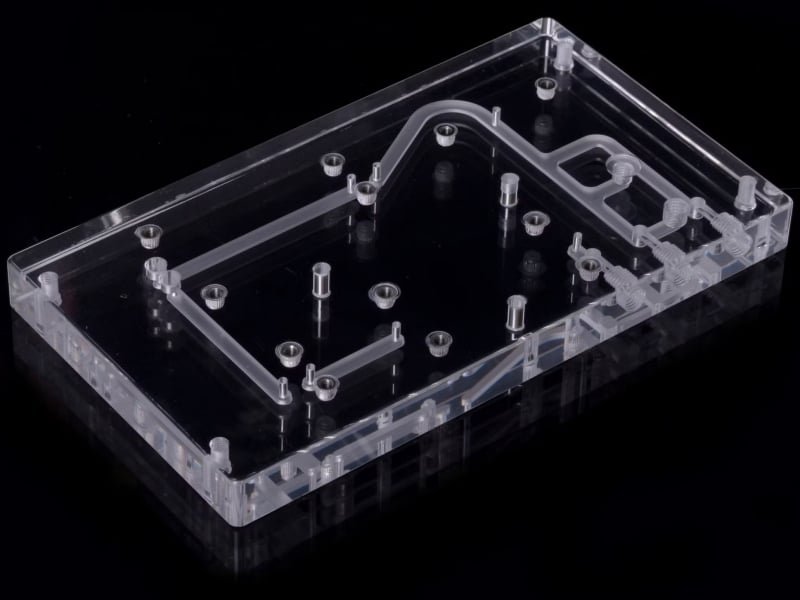

Acrylic (PMMA) CNC Machining Service

We Offer Acrylic CNC Machining Service Specific to Your Needs!

- Experience with clear and colored acrylics

- Tight control over dimensional tolerances

- Smooth, chip-free edges and clean surface finishes

- Post-processing: tapping, threading, polishing

- Custom surface finishes and inserts

What is Machined Acrylic (PMMA)

Machined acrylic, also know as PMMA (polymethyl methacrylate), it is the most common transparent plastic that often used as alternative to glass. Acrylic machining parts are widely used in many applications, especially when you need clarity, good impact strength, and weather resistance.

Types of PMMA Machining We Offer

Machined Arcylic Properties

Following are some of the key material properties that matter most, please note that the data shall change based on Arcylic grade.

| Item | Value |

|---|---|

| Tensile Strength | 8,000 – 11,000psi |

| Flexural Strength | 12,000 – 17,000psi |

| Light Transmission | Up to 92% |

| Heat Deflection Temperature | 65 – 100°C |

| Machinability | Good |

| Water Absorption (24 hrs) | 0.2 – 0.3% |

-

Key Benefits of Acrylic CNC Machining

- Excellent optical clarity makes it ideal for lenses, covers, and viewing windows.

- Machined Acrylic parts can meet tight tolerances

- PMMA material is stable and rigid, it can holds shape well under light mechanical load.

- Arcylic is resitant to UV and weather makes it suitable for both indoor and outdoor applications.

- Arcylic machining parts are easily to achieve good surface finish and clean edges with proper feeds an tools.

-

Shortcomings of Acrylic CNC Machining

- Arcylic is brittle compared to other plastics, it can get crack or chip during machining.

- It is not suitable for higt-heat environments as it get soften at relatively low temperature.

- If not handled properly, the surface can scratch easily.

- PMMA requires longer machining time to avoid creacking.

Polupar Acrylic Machined Part

Here are some popular ABS machined parts we have made:

- Light diffusers

- Display windows and panels

- Transparent covers and guards

- Optical lenses and light guides

- Sight glasses

- Instrument panels

- Spacer blocks

Have a Question?

Additonal Options for Acrylic Parts

Related Acrylic Machining Resources

Thermoforming vs injection molding, both are popular plastic manufacturing techniques. The two processes are good

Injection molding flow marks are a common and often perplexing defect observed in molded plastic

Sink marks in injection molding are a common yet troublesome defect that can compromise the