Injection molding is popular in various industries, from automotive to healthcare, as a technical force for reshaping modern manufacturing. It plays a vital role in encouraging innovation and accelerating mass manufacturing.

The first method of injection molding used basic machinery, refers to injection molding tooling to create simple objects like hair combs, buttons, etc. With the advancement of newer plastics, such as polyethylene, polypropylene, and polystyrene, it became easier to turn molten materials into detailed shapes.

This blog is a guideline to help you understand the world of injection molding tooling.

Injection Mold Design Fundamentals

Precision is a critical factor in manufacturing, and mold design is essential for determining the quality and affordability of production. Here are five fundamental mold design elements that are key for the completion of manufacturing procedures.

Selecting The Right Mold Material

A successful design foundation requires choosing the right mold material. The material affects the accuracy and standard of the finished product, besides the longevity of the mold. Every option, from conventional metals like steel to new materials like aluminum and alloys, has specific benefits and things to keep in mind. To make informed choices about the mold material, one must grasp the specific demands of the production process.

Balancing Production Volume and Mold Durability

A key factor when calculating a mold’s durability is the production volume. Molds that endure repeated wear and tear are necessary for high-volume production. In contrast, a less robust and more economical mold is enough for low-volume production. The correct balance between cost and durability is struck to maximize manufacturing productivity and sustain product quality over time.

Ensuring Compliance With Strict Standards for Tolerance and Precision

In manufacturing, precision cannot be compromised, along with establishing and maintaining tight tolerances that depend heavily on mold design. Every element, from the mold’s design to machining methods, ensures that the final product satisfies the specifications. A well-designed mold will consistently create parts that are within the required tolerances.

Streamlining The Manufacturing Process Through Effective Cycle Times

Cycle times, or how long it takes to carry out one production cycle, are often used to gauge industrial efficiency. It is influenced by mold design factors like cooling system effectiveness, ejection mechanisms, and component remolding. The cycle durations are shortened, increasing productivity and overall expense by making these components more efficient.

Implementing Strategic Tool Changes for Minimum Downtime

The time it takes to switch out tools becomes important when several molds are used in a manufacturing process. Tool switching must be done quickly and effectively to reduce downtime and increase overall production. The productivity of the manufacturing process is affected by mold design concerns for immediate and accurate tool changeover.

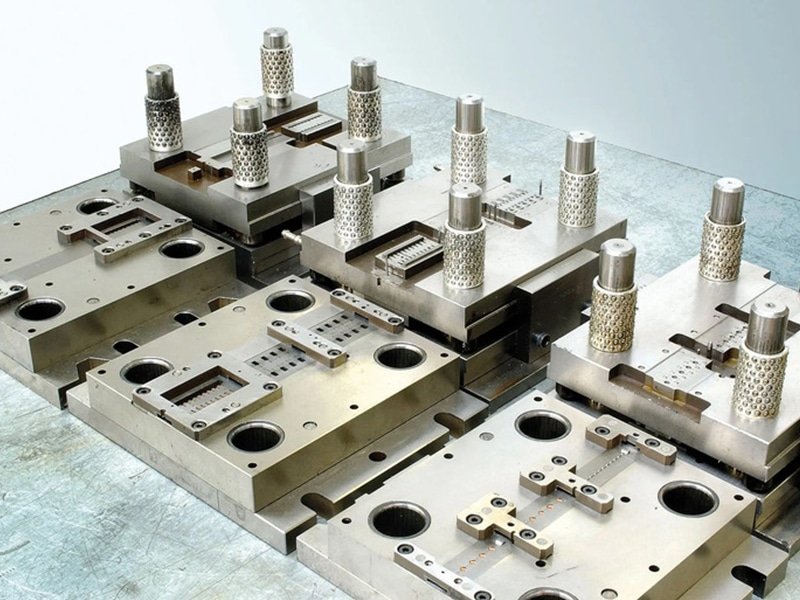

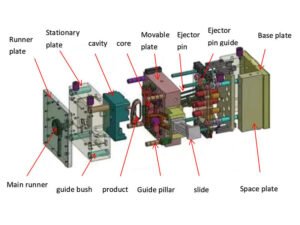

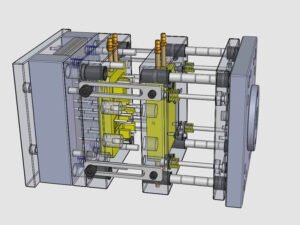

Injection Molding Tooling Components

High-quality plastic parts are produced through the complex manufacturing process of injection molding, which depends on many delicate components. For the injection molding process to be precise and effective, it is essential to comprehend these elements. These are ten fundamental injection mold components, along with an outline of their functions and significance.

| Component | Function | Significance |

|---|---|---|

| 1. The Mold Base | Promotes stability and alignment by providing other mold components with a strong foundation. | Throughout the injection molding process, the mold foundation sustains all aspects of the mold structure, absorbing pressure and preserving accuracy. |

| 2. Core Plate | Regulates the proportions and complexity of the molded part by shaping its interior characteristics. | The core plate is vital to the quality and is necessary to achieve the correct form and precision of the finished product. |

| 3. Cavity Plate | Contributes to the molded part's surface quality and appearance by defining its external features. | The hollow plate plays an integral part in giving the product the proper aesthetics, affecting how it looks and feels in the end. |

| 4. Sprue Bushing | Melts plastic and channels it into the mold using an injection molding machine. | The sprue bushing starts the molding process precisely and consistently by guaranteeing a controlled and effective flow of plastic. |

| 5. Runner System | Allows for consistent filling by distributing plastic material from the sprue to individual cavities. | For uniform part quality, the runner system maximizes material distribution by reducing variances and flaws across several cavities. |

| 6. Ejector Pins | When the mold has cooled, push the molded item out of it. | Ejector pins are important for flawless part ejection, damage prevention, and a seamless mold-to-product transition. |

| 7. Cooling Channels | Control the mold temperature to avoid warping and guarantee the constant quality of the parts. | Cooling channels help produce high-quality, dimensionally stable products by improving mold longevity and cycle time optimization. |

| 8. Venting System | Releases air during injection, reducing the possibility that the finished product has air pockets. | A thorough venting system is necessary for avoiding flaws and improving the molded part's aesthetic and structural integrity. |

| 9. Guide Pins and Bushings | Make sure the mold halves are properly aligned to avoid misalignment problems. | Mold halves are ensured to mate precisely by guide pins and bushings, which lowers the possibility of errors and preserves dimensional accuracy. |

| 10. Ejector Retainers | Keep the ejector pins firmly in place when operating. | Throughout molding, ejector retainers stabilize the ejector pin mechanism, guaranteeing consistent and dependable component ejection. |

Understanding how these elements work together is the key to successful injection molding. The part’s shape is defined by the cavity plates and core, while the mold base offers the structural framework. The runner system and sprue bushing enable the regulated flow of molten plastic, guaranteeing even filling of the mold cavities.

Ejector pins and ejector retainers are vital tools in the demolding process because they provide a smooth and damage-free release of the molded object. A venting system and cooling ducts help to keep the mold at the ideal temperature and avoid flaws like air entrapment or warping.

Read our blog to learn all the Injection Molding Mold Parts and Their Roles

The secret to getting reliable, top-notch results from the injection molding process is the joint effort of these elements. The optimal arrangement of these components remains an important focus for improving precision and productivity in the plastics manufacturing process as technology develops.

Injection Molding Tooling Life

Injection molding tool life is the number of production phases it can handle before needing to be changed or fixed. The steps in a production cycle include shutting the mold, injecting some molten plastic, cooling, opening the mold, and removing the part. It is difficult to predict how long an injection mold will last, but we can help you identify the best tool for prototyping or high, medium-, or low-volume manufacturing.

Classifications of Injection Molding Tooling

Five classifications of molding tools are defined by the trade organization SPI (Society of the Plastics Industry), which has been relaunched as PLASTICS. They offer an easy approach to evaluating injection-molded plastic tooling through the lenses of production phases, which relate to various numbers, and manufacturing quantity, which acts as a quantitative measurement.

| SPI Mold Class | Volume | Cycles |

|---|---|---|

| 101 | High | Over 1 million |

| 102 | Medium-to-high | 500,000 to 1 million |

| 103 | Medium | Under 500,000 |

| 104 | Low | Less than 100,000 |

| 105 | Prototype | Less than 500 |

Tips to Improve Molding Tooling Life

Tool life is a crucial factor in injection molding. The term “tool life” describes how long a mold is used efficiently before it needs to be fixed or replaced. The total quality, expense, and efficiency of injection molding operations are all impacted by the longevity of these instruments. Maximizing tool life needs careful material selection, attentive maintenance, and tactical operational methods. Here are some pointers for extending the tool mold’s life:

Selecting The Right Materials to Extend Tool Life

Proper selection of high-quality components is a fundamental principle of prolonging tooling life. The use of durable materials enhances equipment longevity. Modern ceramics, carbides, and high-speed steels are materials with exceptional performance used in many manufacturing applications. High-quality materials are invested in by manufacturers to prevent early wear and ensure tool survival in machining operations.

Using Coolant Strategies That Work to Manage Heat Build-Up

An important aspect of reducing wear, heat, and friction during machining operations is lubrication. Sufficient lubrication lowers the chance of tool wear and improves the operation’s efficiency. Manufacturers must assess the requirements of their applications and implement appropriate lubrication procedures. Using cutting fluids, oils, or specialty coatings made to form a barrier against wear caused by friction is necessary for this. Lubricating systems require routine maintenance for tools to last longer and function consistently.

Following Strict Guidelines for Tool Inspection and Maintenance

Accurate tool calibration is required to obtain the highest productivity and durability. Inaccurately calibrated tools wear unevenly and produce less-than-ideal outcomes. The maintenance schedule should include regular inspections and calibration procedures to find any abnormalities and fix them immediately. The use of this proactive strategy contributes to the creation of precise and high-quality components while also enhancing the tool’s durability.

Using Advanced Coating Technologies to Increase Wear Resistance

Heat is a universal enemy that reduces performance and speeds up tool wear. Managing and dispersing heat produced during machining operations requires the implementation of efficient cooling techniques. Temperature control techniques such as air blasts and cooling systems are used to keep the temperature within reasonable bounds. Besides reducing wear, heat control keeps tools from thermally distorting and guarantees that their dimensions will be stable over time.

Tool Path Strategies Refined for Evenly Distributed Wear

The link between cutting speeds, feeds, and tool life is complicated. Manufacturers who perform specialized machining operations must determine and apply the right feeds and speeds. Excessive speeds or feeds when operating tools cause increased wear, while conservative settings produce ineffective machining. Finding the proper balance through thorough examination and adjustment helps increase tool life and maximize productivity.

Implementing Optimal Chip Control for Improved Tool Life

Maintaining tool integrity requires effective chip control. Inadequate chip evacuation results in chip recutting, increased friction, and heat creation, which contributes to premature tool wear. Maintain clean-cutting conditions by using appropriate chip control techniques, such as chip breakers, optimized tool geometries, and well-thought-out cutting procedures. This helps to provide high-quality surface finishes and extends the life of the tool.

Strict Inspection Procedures to Find Anomalies Early

The early identification of any deviations or anomalies in the tooling system depends heavily on the implementation of strict inspection standards. Periodic inspections carried out with great care and attention to detail allow manufacturers to see possible problems before they become more serious. This proactive strategy prolongs tool life by minimizing downtime and facilitating prompt remedial actions that maintain tool integrity.

Invest in Wear Resistance with Advanced Surface Treatments

Investing in advanced surface treatments specifically tailored for wear resistance increases mold and dies’ durability. Surface coatings that reduce wear and friction include PVD (physical vapor deposition), and nitriding creates a protective barrier. Manufacturers strengthen their tools against the hard circumstances of frequent molding cycles by adding these treatments to the tooling plan, which extends tool life.

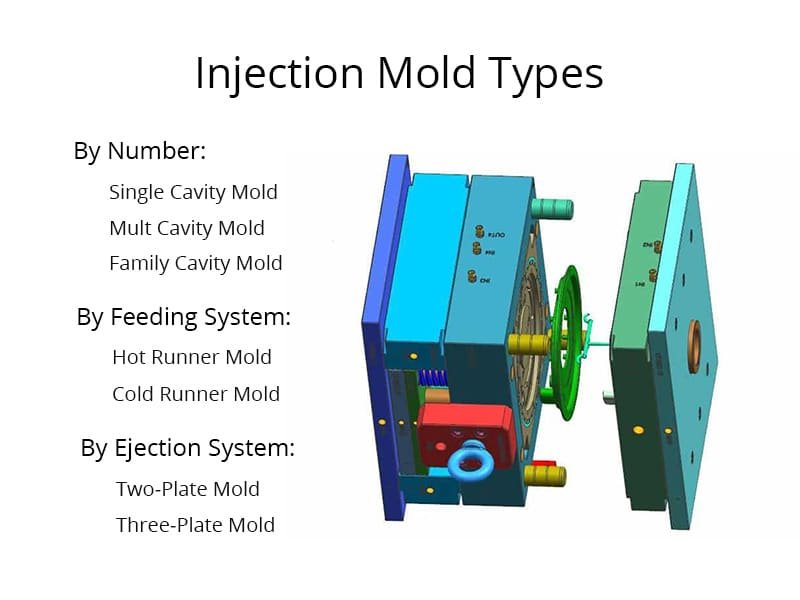

Injection Mold Type

Picking a proper mold type counts for forming the finished product. Let’s examine the three main varieties of mold, each of which affects the outcome differently.

Based on the Feeding System

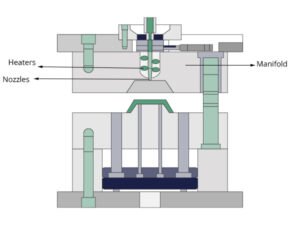

Hot Runner Injection Mold

In the realm of efficiency, the hot runner injection mold takes center stage. This type of mold system is designed to maintain a consistent temperature in the runner channels, preventing the material from solidifying prematurely. As a result, cycle durations are shortened, material waste is kept to a minimum, and overall product quality is raised. This technique is useful in high-volume manufacturing settings where accuracy and speed are important.

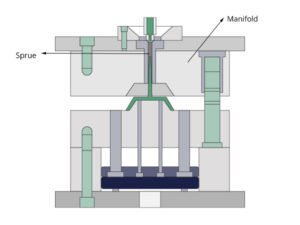

Cold Runner Injection Mold

Contrary to its hot counterpart, the cold runner injection mold relies on unheated channels to guide the molten material. While it may not match the hot runner in terms of speed, the cold runner mold is favored for its simplicity and cost-effectiveness. This mold type is often the preferred choice for smaller production runs or situations where material waste is a critical consideration.

Based on the Number of Cavities

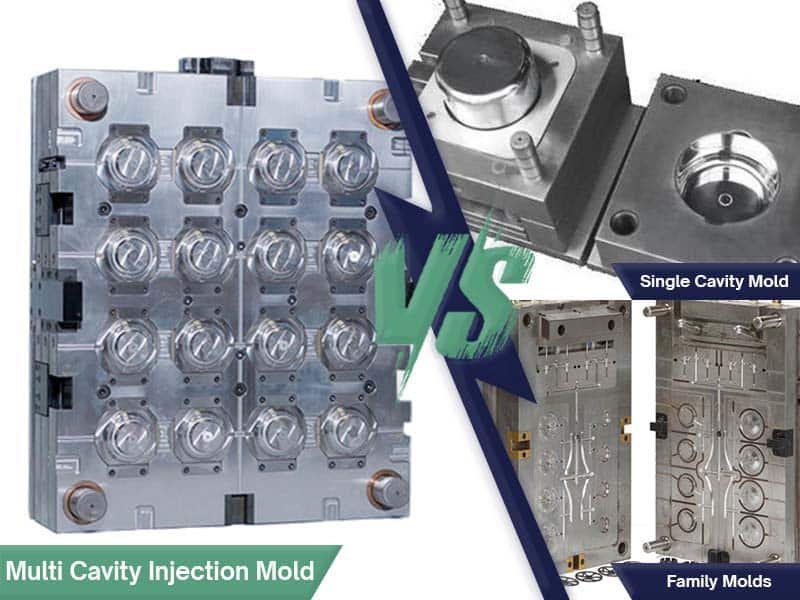

Single Cavity

Precision takes the lead in single cavity molds, where each tool produces a single unit at a time. This mold is perfect for elaborate designs and prototypes that require close attention to detail. Although it might not be the fastest option for high-volume production, the single cavity mold shines when it comes to maintaining product integrity.

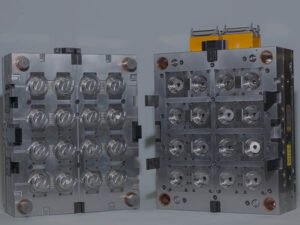

Multi-Cavity

Efficiency and productivity reach new heights with multi-cavity molds. By incorporating multiple identical cavities into a single mold, manufacturers can produce several units in a single cycle. This method is the preferred option for large-scale manufacturing since it greatly speeds up the production process. It takes careful thought to strike a balance between cavity count and expenses associated with cycle time and tooling.

Family Mold

The family mold takes versatility to a whole new level by incorporating different parts or products into a single mold. This approach is particularly useful when manufacturing products with multiple components that are interrelated. It streamlines the production process, ensuring that all components are produced simultaneously, minimizing assembly time.

Based On The Mold Plate

Two Plate Mold

Simplicity and ease of use define the two-plate mold, where a stationary and a movable plate make up the structure. This mold type is a straightforward solution for less complex parts. While it may not be as versatile as other types, the two-plate mold is a reliable and cost-effective option for many applications.

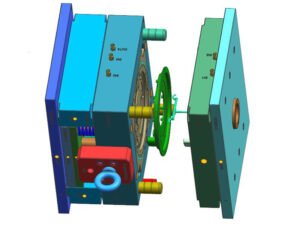

Three Plate Mold

In pursuit of increased complexity and flexibility, the three-plate mold introduces an additional runner plate. This extra plate allows for greater control over the molding process by enabling the separation of runners and parts in different directions. Although it may involve a more intricate setup, the three-plate mold is indispensable when dealing with intricate designs and complex part geometries.

Engineering Consideration

Engineers work behind the scenes to ensure perfect results by navigating a complex web of variables. Below is an overview of important engineering factors:

Material Marvels

Selection must be done carefully. When selecting the ideal plastic partner, engineers consider a variety of characteristics, including mechanical qualities, melt flow, and thermal stability.

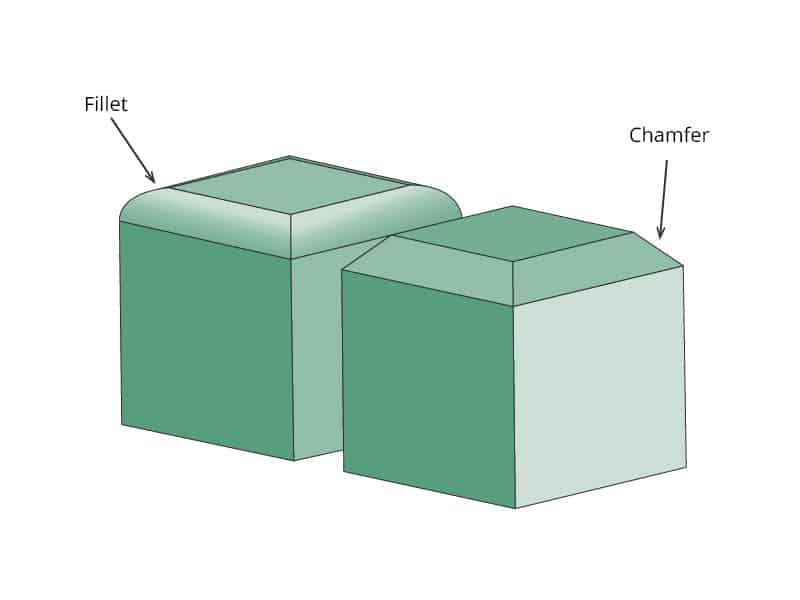

Mold Magic

The creation of a mold is a form of art. Engineers assure consistency and eliminate faults by carefully crafting part shapes, optimizing gating techniques, and strategically embedding cooling channels.

Mastery Of The Machine

The injection molding machine is an asset, not merely a tool. Engineers adjust variables like cycle time, pressure, and temperature to work in unison with every component and material.

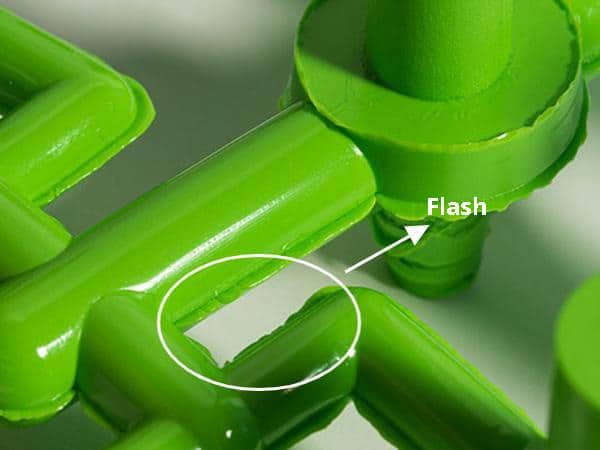

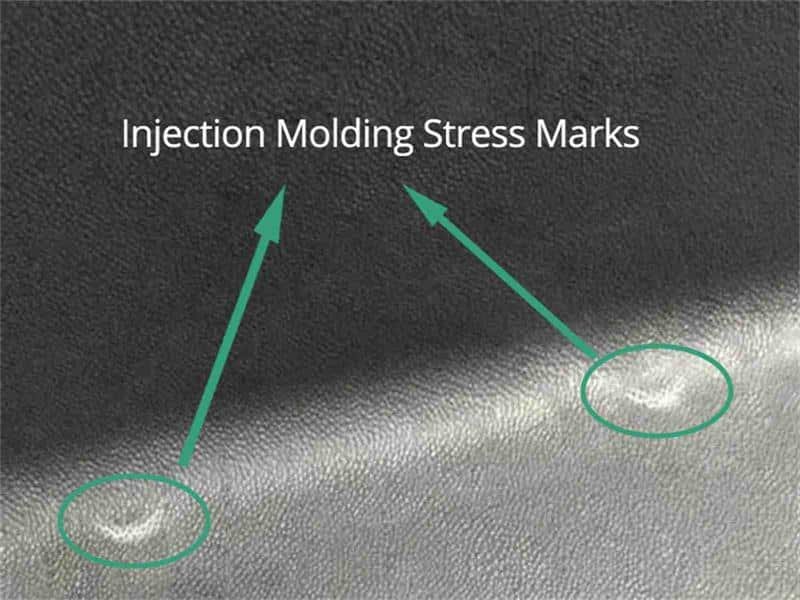

Getting Rid Of Flaws

You have to defeat warping, shrinkage, and residual tensions. Engineers assess, change tooling, and fine-tune processing conditions to assure excellence.

Alert Vigilance

The unsung heroes in this situation are quality control and ongoing observation. Engineers maintain a close check to make sure that each molded piece adheres to the design requirements.

Conclusion

Injection molding is a multipurpose yet effective manufacturing technology. The outcome of the manufacturing process is determined by mold selection, though. It comes down to characteristics such as feeding method, number of cavities, and mold plate.

Designing injection mold tooling is a highly skilled and technical operation that needs to be handled and controlled expertly. Reach out to us about delivering premium injection molding services.