Injection molding splay is a common defect that can compromise the appearance and quality of plastic parts. Understanding its causes and implementing effective solutions are critical for achieving flawless finishes and maintaining production efficiency. This guide explores the intricacies of splay, offering actionable insights to identify, prevent, and resolve this issue for consistently high-quality results.

What is Injection Molding Splay?

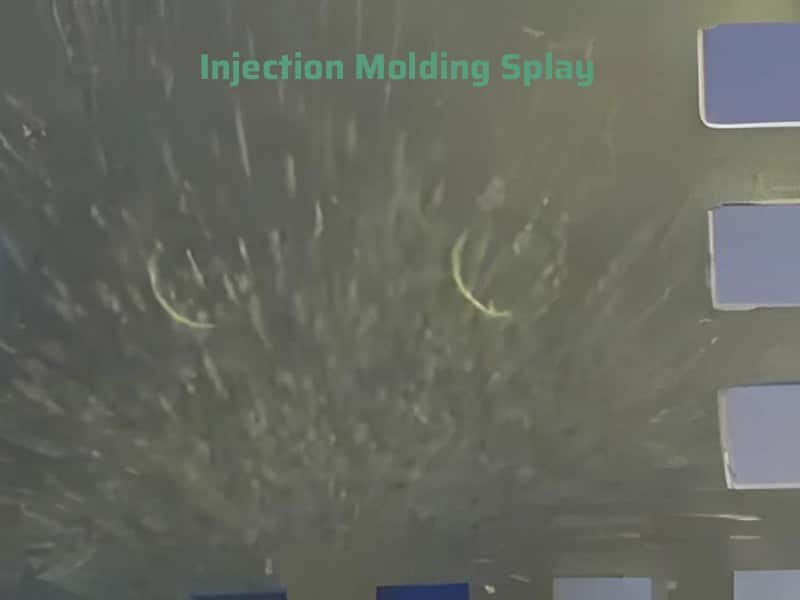

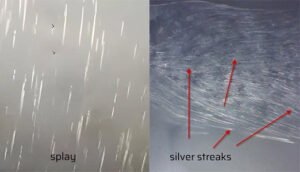

Injection molding splay refers to a common defect that appears as streaks or lines on the surface of molded plastic parts. These streaks, often described as “silver streaks,” are a result of improper material flow, contamination, or trapped gases during the molding process. Splay marks injection molding defects can compromise the aesthetic and functional quality of parts, making their prevention a priority for manufacturers. Understanding the root causes and solutions to splay in injection molding is essential for maintaining the integrity of production processes.

Why Splay is a Common Issue in Injection Molding Processes?

Splay occurs frequently in injection molding due to the inherent complexity of the process. Variables such as material properties, machine settings, and environmental conditions all contribute to this defect. High moisture content in resins, improper mold temperatures, or contamination in the feedstock can easily disrupt the smooth flow of materials, leading to the formation of splay on plastic parts. As a ubiquitous challenge, it demands careful attention and precise adjustments to ensure defect-free production.

Impact of Splay on Injection Molded Parts

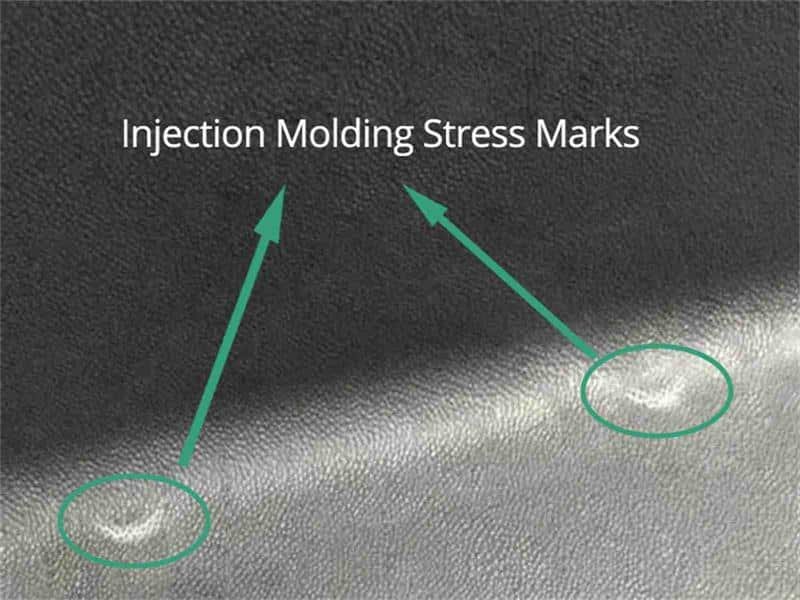

The presence of splay marks on plastic parts is more than a cosmetic issue. While it detracts from the surface finish and visual appeal, it can also indicate deeper problems within the material or process. Splay injection molding defects may signal incomplete polymer fusion, leading to weaker mechanical properties and reduced durability. In critical applications, such as medical or automotive components, these defects can compromise the part’s performance and reliability, underscoring the need for effective troubleshooting and resolution.

Causes of Splay in Injection Molding and How to Fix

Splay in injection molding arises from a combination of factors that affect material flow, temperature, and cleanliness. By understanding these causes, manufacturers can implement targeted solutions to minimize or eliminate the defect.

Moisture in the Material

Moisture is one of the leading causes of splay in injection molding. When plastic resins absorb water, the heat during processing converts this moisture into steam, which manifests as streaks on the molded part. High-humidity environments exacerbate this issue, especially with hygroscopic materials such as nylon and polycarbonate.

How to Fix:

Proper drying of plastic resins is critical to eliminating moisture-related splay. Using desiccant dryers or hopper dryers ensures that materials reach the recommended moisture levels before molding. Regular monitoring of drying equipment and adherence to drying guidelines can significantly reduce the risk of splay injection molding defects.

Excessive Injection Speed and Pressure

Excessive injection speed and pressure can disturb the material flow, causing turbulence and the formation of gas pockets within the mold cavity. This disturbance often results in the appearance of injection molding splay marks, as trapped gases or unmolten particles disrupt the surface.

How to Fix:

Adjusting the injection speed and pressure to optimal levels can prevent turbulence and ensure smooth material flow. Gradual ramping of speed during the injection phase and maintaining consistent pressure throughout the process can help achieve uniform part quality.

Improper Mold Temperature and Cooling Rate

Temperature discrepancies in the mold can lead to uneven cooling, which affects how materials flow and solidify. Overheated zones can cause polymer degradation, while cooler zones may trap gases or introduce flow marks, including splay on plastic parts.

How to Fix:

Proper mold temperature control is essential for avoiding splay. Using precision mold temperature controllers and ensuring uniform cooling across the mold surface can reduce defects. Regular calibration of temperature sensors and maintaining proper thermal insulation are also effective strategies.

Contamination in Material and Machinery

Contaminants, whether in raw materials or machine components, are another significant cause of splay. Foreign particles, degraded polymers, or leftover residues in the barrel can introduce inconsistencies that lead to the formation of splay injection molding defects.

How to Fix:

Maintaining cleanliness in the molding environment is key. Conducting regular machine maintenance, thoroughly purging equipment between material changes, and using high-quality, contamination-free resins are crucial steps. Implementing quality control checks for incoming materials can further prevent contamination-related splay issues.

Important Note: Always consult the material manufacturer’s recommendations for processing temperatures and drying times. If you’re unsure about the cause of splay or how to correct it, it’s best to consult with an experienced injection molding technician.

Key Design Considerations to Minimize Splay in Injection Molding

It’s much easier to prevent splay at the design stage than to fix it later. Designing parts with the potential for reduced splay requires a strategic approach. Here are some key design considerations to minimize splay in injection molding:

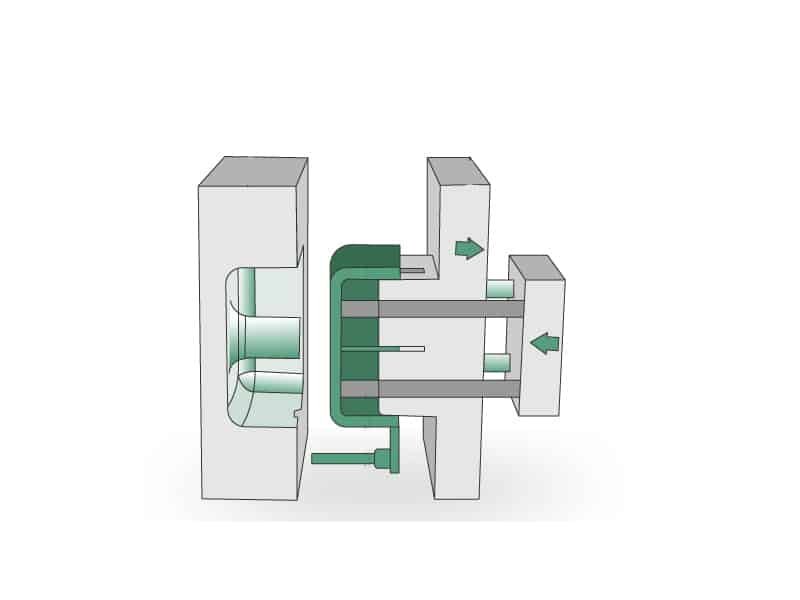

- Gate Design: Careful consideration of location to ensure even filling of the mold cavity, appropriate sizing to allow smooth and consistent flow, and selection of the correct gate type (e.g., sprue, runner, pin) based on the part design and material properties to minimize shear and prevent splay.

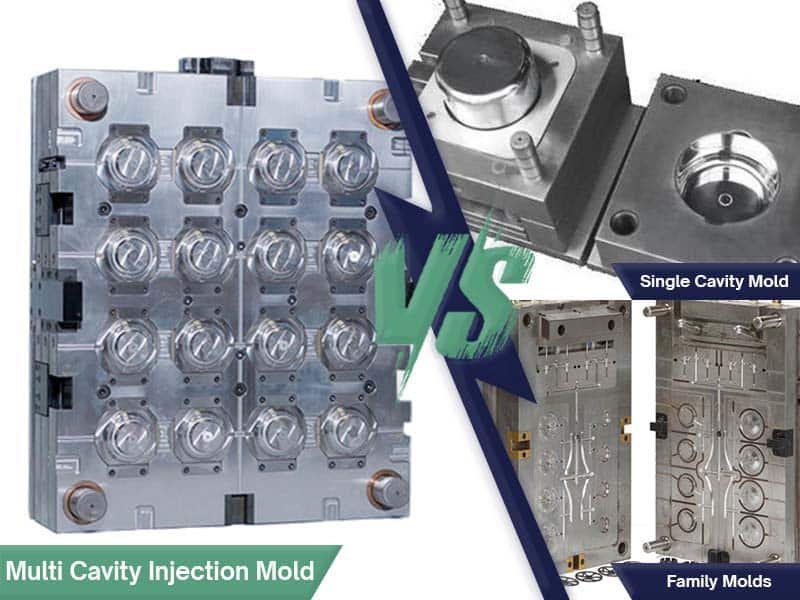

- Runner Design: Optimize size and shape to minimize pressure drop and ensure uniform melt flow to all gates, while the runner layout should be balanced to ensure that all parts of the mold cavity fill at the same rate, avoiding flow imbalances that can contribute to splay.

- Part Design: Maintain consistent wall thickness throughout the part to promote uniform cooling and prevent variations in shrinkage which can lead to splay, minimize sharp corners or edges which can create areas of high shear and increase the risk of splay, and incorporate adequate venting to allow trapped air or gases to escape from the mold cavity, preventing them from being compressed and causing splay.

- Mold Design: Include strategically placed cooling channels to ensure uniform cooling of the mold, which helps to prevent variations in shrinkage and reduce the risk of splay, and incorporate a smooth mold surface finish to facilitate easy release of the part and prevent defects that can mimic or exacerbate splay.

- Material Selection: Consider the material’s melt flow index (MFI), choosing a material with an appropriate MFI for the part design to ensure proper flowability and reduce the risk of splay, and carefully consider the material’s moisture absorption characteristics, ensuring proper drying before molding to eliminate moisture-related splay.

- Collaboration: Involving mold flow analysis to simulate the filling process and identify potential issues such as areas of high shear or poor venting before mold construction, and early engagement with experienced mold designers and injection molding technicians to get their input and ensure manufacturability are crucial for preventing splay and other molding defects.

Splay vs Silver Streaks: What Are the Differences

Splay in injection molding is frequently confused with silver streaks, a separate but related defect that also appears as streaks on the surface of molded parts. While both defects can look similar to the naked eye, the causes and manifestations are distinct.

Splay marks are typically caused by moisture in the material or incorrect machine settings, while silver streaks usually arise from contamination in the material or the mold. Splay often appears as thin, glossy streaks running parallel to the flow direction, whereas silver streaks are often broader and may have a different sheen, resembling a more metallic finish. Understanding the differences between the two defects is crucial, as they require different corrective actions. While drying materials or adjusting process parameters can fix splay, eliminating silver streaks may necessitate a more thorough cleaning of the equipment or switching to a different batch of resin.

Conclusion

Injection molding splay is a common and challenging defect, but with a thorough understanding of its causes and solutions, it is possible to minimize or completely eliminate it from the production process. By focusing on design considerations, material handling, and precise machine settings, manufacturers can reduce the occurrence of splay marks injection molding defects. Effective management of splay in injection molding not only improves the aesthetic and mechanical properties of molded components but also enhances overall production efficiency and product reliability.