Injection molding cracks are a frequent issue in plastic part production. This defect affects part strength and appearance, leading to higher scrap rates, processing adjustments, and increased production costs.

What is an Injection Molding Cracks Defect?

Injection molding cracks occur when parts develop fractures during or after the molding cycle. These cracks compromise structural integrity and require analysis of processing, material, and design factors. Some cracks appear immediately post-ejection, while some ones emerge later. Addressing injection molding cracks should involve understanding their types, causes, and remedies.

Types of Cracks

Injection molding cracks defect manifests in several forms based on timing and location.

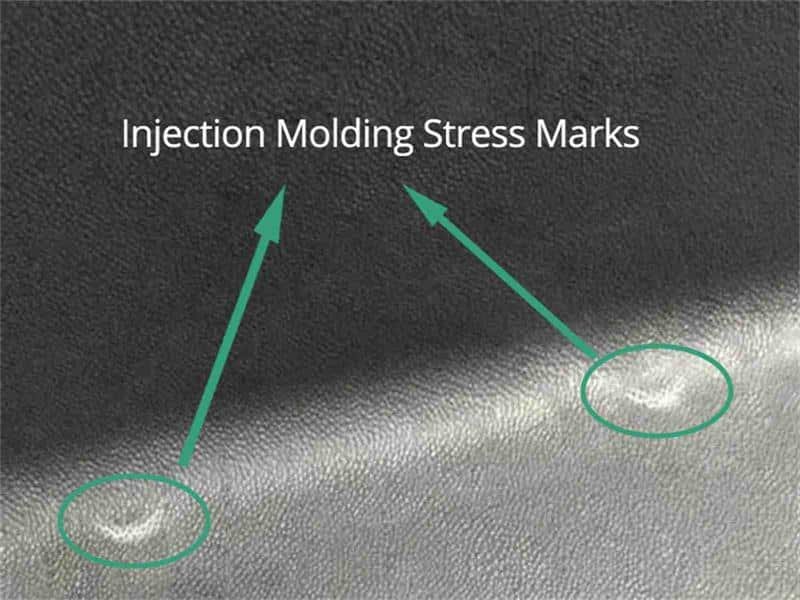

- Surface cracks form during part ejection due to rapid cooling and differential shrinkage. These molding cracks appear as fine lines on external surfaces.

- Internal cracks develop within the part thickness after molding. Residual stresses from uneven cooling cause these crack defect instances over time, often under load or environmental exposure.

- Stress cracks concentrate near corners or thin sections. Uneven material flow and shrinkage create high tensile stresses, resulting in injection molding cracks along these zones.

- Delayed cracks are associated with design elements like metal inserts. Thermal expansion differences between plastic and insert materials induce molding cracks during temperature changes post-molding.

Common Locations Where Cracks Typically Appear

Cracks often form in specific areas of molded parts.

- The gate area is one common location where the plastic enters the mold cavity. High shear stress in this area can initiate injection molding cracks.

- Along knit lines or weld lines, where two flow fronts meet, cracks may develop due to weak bonding. These lines form when molten plastic flows around obstacles in the mold.

- Sharp corners or areas with wall thickness transitions are prone to crack defects.

- Near the parting line or at ejector pin marks, molding cracks can occur if ejection is improper.

Causes of Injection Molding Cracking

Several factors contribute to cracking defects in plastic injection molded parts.

Processing Factors

The following process parameters combine to produce injection molding cracks in high-volume runs.

- Excessive injection pressure generates high shear rates, building internal stresses that lead to cracks.

- High injection speed exacerbates this issue by trapping air and causing flow imbalances.

- Low mold temperature results in brittle parts prone to molding cracks during demolding.

- Prolonged holding pressure locks in differential shrinkage, promoting crack defect formation.

- Slow or uneven ejection applies excessive force, splitting parts along weak planes.

- Inadequate cooling time fails to stabilize dimensions before ejection.

Material Issues

Material properties influence susceptibility to injection molding cracks.

- High levels of recycled content reduce tensile strength and ductility, increasing molding cracks.

- Moisture in resin hydrolyzes polymers during melting, weakening molecular chains, especially in hygroscopic materials like nylon.

- Incompatible additives or contamination alter flow and cooling behavior. Lubricants or pigments can create weak interfaces, leading to injection molding cracks under stress.

- Material viscosity mismatches in blends cause uneven filling, further promoting molding cracks.

Mold and Design Problems

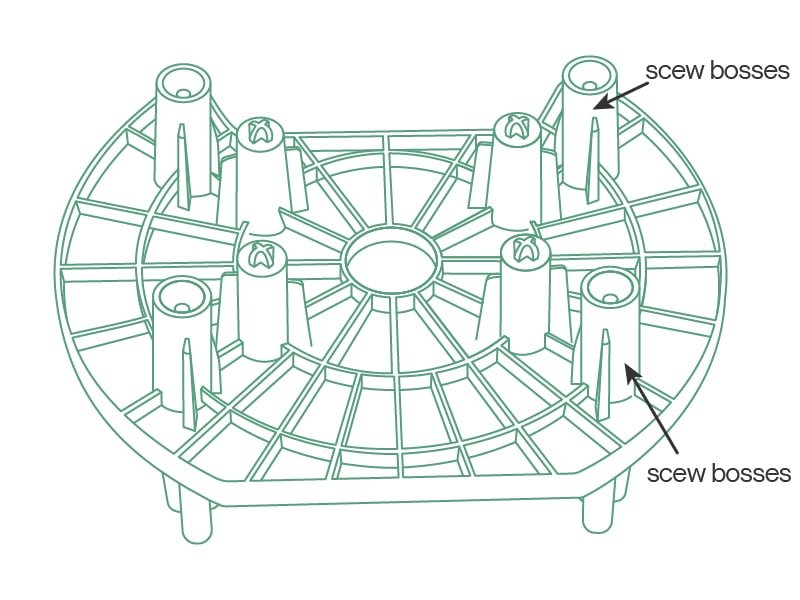

Mold design flaws trigger injection molding cracks through stress concentrations.

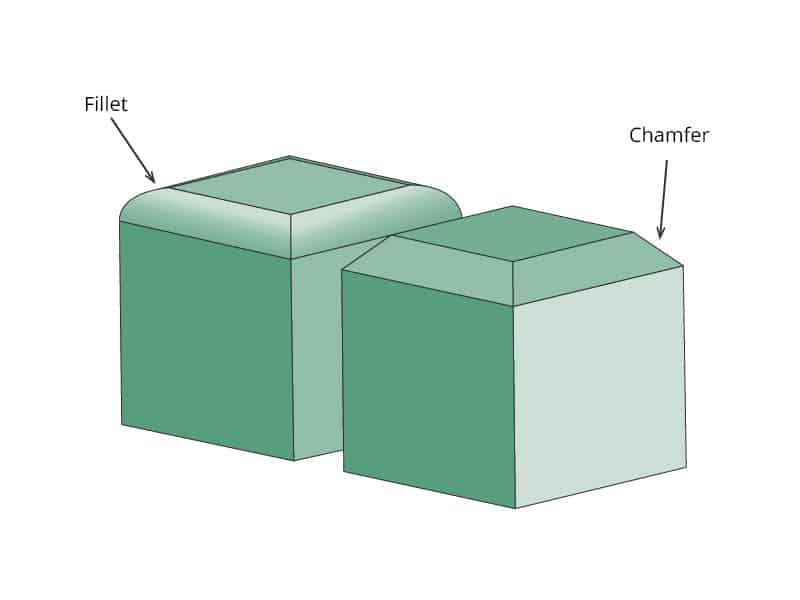

- Sharp corners without fillets act as crack initiation sites due to shrinkage gradients.

- Insufficient draft angles on vertical walls make ejection difficult, applying excess force that initiates injection molding cracks.

- Poor venting allows gas entrapment, generating hot spots and localized overheating. This thermal imbalance results in molding cracks near vent areas.

- Gate location imbalances create weld lines with reduced strength. These zones become crack defect locations under tensile loads.

- Poor Thick-to-thin section transitions amplify cooling rate differences, then cause cracks.

- A poorly designed ejector system or pin placement concentrates force on small areas, damaging the part during ejection.

Machine Limitations

Machine wear contributes to injection molding cracks defect over time.

- Worn screws and barrels produce inconsistent melting, leading to unmelted particles and weak spots.

- Insufficient plasticizing capacity fails to homogenize shear heat.

- Low back pressure settings result in poor mixing, increasing molding cracks.

- Clamping force inadequacies cause flashing, which indirectly stresses parts.

Prevention Strategies for Injection Molding Crack Defect

Effective prevention of injection molding cracks starts with optimized processing.

- Increase mold temperature to 10-20°C above minimum for easier ejection and reduced brittleness.

- Balance barrel temperature profile to ensure uniform melt flow. Lower injection pressure and speed to minimize shear-induced stresses leading to molding cracks.

- Dry resins to below 0.02% moisture content before processing. This step eliminates hydrolysis-related injection molding cracks in sensitive materials.

- Implement gradual pressure drops during the packing phase. Shorten holding time to avoid overpacking and residual stress buildup.

- Design molds with rounded corners and adequate draft angles. Add vents at the end-of-fill areas to prevent gas-related crack defect.

- Maintain uniform wall thickness. Use annealing cycles post-molding to relieve internal stresses from injection molding cracks.

- Select resins with matched shrinkage rates for multi-material parts. Conduct design reviews early to eliminate potential molding crack sources.

Troubleshooting Steps for Injection Molding Cracking Defects

Systematic troubleshooting resolves injection molding cracks efficiently.

Inspect parts for ejection pin marks or corner sticking, indicating stress cracks.

Measure material moisture with a hygrometer. Levels above 0.05% confirm material-related molding cracks cause.

Review machine logs for pressure and speed profiles. Spikes correlate with processing-induced injection molding cracks defect.

Examine mold for wear or misalignment. Simulate flow with molding software to identify gate and vent issues leading to crack defect.

Test prototypes with adjusted parameters incrementally. Document changes and outcomes to establish optimal settings for zero molding cracks.

Conclusion

Injection molding cracks defect is a common challenge in plastic manufacturing processes. However, identifying causes promptly and eliminating contributing factors enables the production of high-quality injection molded products. Erye is an experienced injection molding manufacturer and provides professional injection molding services. Contact Erye for consultations and get customized solutions for high-quality molded products.