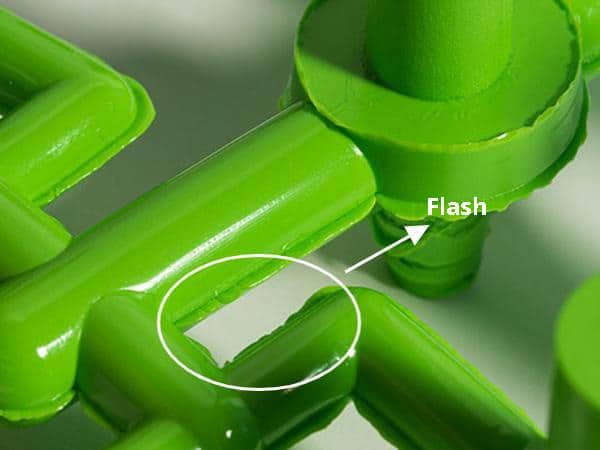

Flash in injection molding is one of the most common plastic molding defects. It significantly affects plastic parts quality. This is a thin layer of excess material that appears at parting lines where mold halves meet.

In simple words, flashing in injection molding is due to the escape of molten plastic from the mold cavity. If you understand flash formation, it will help plastic parts manufacturers to improve product quality and reduce costly rework.

Injection Molding Flash: Mechanisms and Causes

Flash in injection molding forms when molten plastic goes into the gaps in the mold and flows into these spaces. The basic physics behind flash has many important factors. Firstly, molten plastic behavior under pressure changes dramatically during the injection process.

Subsequently, viscosity decides how easily plastic flows through the mold. You see, when the temperature increases, viscosity decreases. Therefore, it makes material more likely to flow into unwanted areas. Moreover, parting line dynamics during mold closure play a crucial role.

Material Properties Affecting Plastic Flash

Viscosity, as the property of any liquid to flow, is central in the injection molding process. Firstly, different polymers have varying temperature sensitivity. In addition, pressure viscosity relationships change how materials behave under molding conditions.

Meanwhile, thermal expansion coefficients affect how much materials grow when heated. This point is noticeable because expansion can push mold halves apart. Consequently, plastic flash becomes more likely as gaps increase.

Mold Related Causes

Parting Line Issues

Environmental contaminants like dust and debris accumulate on parting surfaces. Simultaneously, older, worn-out tooling leads to leakages between mold halves. Moreover, misalignment of mold halves creates uneven gaps. Furthermore, mold wear and deterioration over time worsen these problems.

Inadequate Mold Design

Gaps that allow molten material to escape are, like, design flaws. Similarly, poor venting system design or incorrect dimensions prevent proper air evacuation. In contrast, insufficient support structures cannot handle clamping forces. This point is important because weak support leads to mold deflection.

Mold Maintenance Issues

Contamination buildup prevents proper mold closure. Subsequently, if you have damaged and deformed mold surfaces, it will create irregular sealing. Besides, improper mold setup and alignment compound existing problems. At the same time, neglected maintenance schedules allow minor issues to become major defects.

Process Parameter Causes

Flash can develop at different stages of the molding cycle. Several injection molding process parameters cause flashing defects.

Pressure Related Issues

Insufficient clamping force cannot keep the mold halves together during injection. On the other hand, overpressurization during injection forces plastic into small gaps. Subsequently, imbalanced pressure distribution creates hot spots where flash forms. As a result, high pressure leading to increased temperature and flow makes problems worse.

Therefore, the basic point is that pressure control requires careful balance. You know that excessive pressure causes flash while insufficient pressure creates other defects. Ultimately, injection molding companies must find the optimal pressure range for each application.

Temperature Variables

High barrel and nozzle temperatures reduce material viscosity. Likewise, thermal gradients within the mold create uneven flow patterns. Furthermore, inadequate cooling control allows temperatures to drift. Consequently, higher temperature makes fluid more prone to leak through small openings.

The reason is that temperature affects every aspect of plastic behavior. The next thing is understanding how temperature changes throughout the molding cycle.

Flow and Fill Issues

Overfilled molten plastic has nowhere to go except through gaps. Similarly, incorrect injection speed settings create turbulent flow. Meanwhile, poor gate design and placement cause uneven filling. Finally, material residence time problems lead to degradation and unpredictable flow.

Equipment Related Causes

Sprue bushings may lose support to sustain the force of injection pressure. In addition, machine wear and calibration issues affect repeatability. Similarly, hydraulic system problems cause pressure variations. Moreover, tonnage capacity limitations prevent adequate clamping force.

Obviously, equipment maintenance affects plastic flash formation. Why does it matter? Because worn equipment cannot maintain tight tolerances.

Prevention Strategies of Flashing in Injection Molding

Design for Manufacturability Approaches

Design for manufacturability ensures simple and effective features that perform the function rather than focusing on intricate systems. Parting line optimization on edges rather than surfaces reduces flash potential.

You could specify a flash-free mold to ensure and eliminate the molding flash defect from injection molded parts. Proper wall thickness design prevents excessive pressure buildup. Notice things like draft angles and fillet radii that affect mold closure.

Mold Design and Maintenance Solutions

The mold fitting process, by adjusting the mold halves so they come together completely, is essential. Precision machining of parting surfaces creates tight seals. Regular cleaning and contamination prevention maintain mold condition.

Particularly important is preventive maintenance scheduling. Well, it is common for busy shops to delay maintenance. But this leads to more expensive repairs later. Since preventive care costs less than emergency fixes, smart injection molders prioritize regular maintenance.

Process Optimization Techniques

Slow the injection rate to reduce injection pressure and molten plastic viscosity. This approach gives material time to flow naturally without forcing through gaps. Separation is avoided by increasing clamp pressure to press the parts of the mold together and close.

Flow and viscosity are balanced in temperature profile optimization. Cool barrel, nozzle to desired material temperatures. Also, repeated cooling eliminates the thermal gradient that leads to flash.

You will see improved results with systematic process optimization. Generally, small adjustments work better than dramatic changes. Whilst some defects require major corrections, flash in injection molding often responds to minor tweaks.

Quality Control Measures

Process monitoring systems detect problems before they become widespread. Statistical process control implementation tracks trends and identifies root causes. Regular inspection protocols catch problems early.

Operator training and certification ensure consistent practices. In addition, trained operators recognize early warning signs of flash formation. Furthermore, they know how to adjust process parameters correctly.

Flash Removal and Post Processing Methods

Manual Removal Techniques

For low quantities, a razor blade is the most expedient solution for flash removal. Hand trimming methods work well for simple geometries. But safety considerations and tool selection become critical factors.

Subsequently, manual deflashing requires skilled operators who understand part geometry. You must train workers to remove flash without damaging part features.

- Manual Removal Techniques

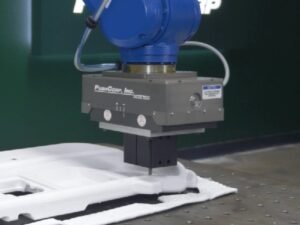

Automated Removal Systems

Sandpaper or vibratory finishing can be used to smooth parting lines on larger production runs. These methods handle high volumes efficiently. Melt the flash into the formed plastic using hot air for thin and fine flashes.

Cryogenic deflashing processes offer excellent results for complex geometries. Cryogenic deflashing lets molders improve surface quality and protect dimensional tolerances. The process freezes flash, making it brittle and easy to remove.

Machining parts manufacturers often prefer automated systems. Because consistency matters more than individual part perfection in high-volume production.

For instance, automotive injection molding companies totally rely on automated systems. They literally process thousands of parts daily. Manual flash removal would be impossible at that scale.

- Automotive Deflashing

Secondary Operations

Machining and finishing operations can remove stubborn flash. Surface treatment applications improve appearance and function. Quality verification after deflashing ensures parts meet specifications.

This point is important because secondary operations add cost. You want to minimize post-processing through better molding practices.

Conclusion of Flashing in Injection Molding

Flash formation in injection molding results from complex interactions between material properties, mold design, and process parameters. Understanding these relationships helps prevent flash formation rather than simply removing it after molding.

Successful flash elimination requires systematic approaches covering mold design, process optimization, and quality control. Modern injection molding companies invest in prevention strategies that reduce long-term costs and improve customer satisfaction through consistent, high-quality plastic parts production.