Design for Manufacturing (DFM) is a critical approach that bridges the gap between product design and production. By integrating design for manufacturing principles early in the design process, businesses can reduce costs, improve quality, and accelerate time-to-market. This blog explores the five core DFM principles—Process, Design, Material, Environment, and Compliance/Testing—and demonstrates how they can transform your manufacturing outcomes. Whether you’re a designer, engineer, or business leader, understanding these principles will help you create products that are not only innovative but also efficient and sustainable.

DFM Principles 1: Process

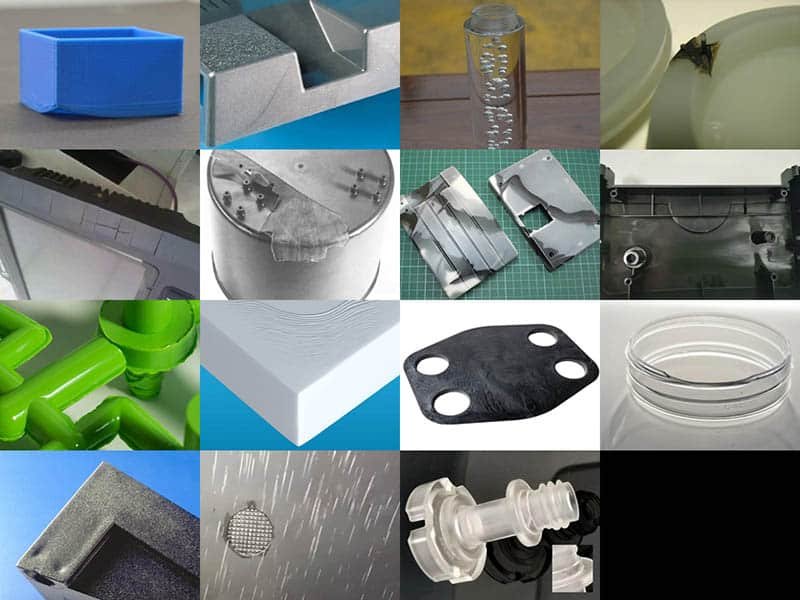

The DFM rule No 1 is process. The manufacturing process you choose directly impacts your product’s cost, quality, and scalability. For example, injection molding is ideal for high-volume plastic parts but requires designs with uniform wall thickness (2-4 mm) and draft angles (1-2°). CNC machining offers precision for metal components but struggles with complex geometries. Additive manufacturing (3D printing) excels in prototyping intricate designs but isn’t cost-effective for mass production.

A study by the Journal of Manufacturing Systems highlights that optimizing the process early in design can reduce production costs by up to 30%. To avoid delays and redesigns:

- Collaborate early with manufacturing engineers to align design and process capabilities.

- Simulate first using tools like mold flow analysis to identify issues.

- Design for scalability (e.g., injection molding for high volumes, 3D printing for prototypes).

Key Considerations:

- Manufacturing Method: Choose the most suitable process (e.g., injection molding, CNC machining, 3D printing, casting) based on the part geometry, volume, and material.

- Process Capabilities: Design parts that leverage the strengths of the chosen process while avoiding its limitations (e.g., avoid undercuts in injection molding or thin walls in casting).

- Tooling and Equipment: Design for ease of tooling and minimize complex setups to reduce costs and lead times.

- Scalability: Ensure the process can scale efficiently for high-volume production if needed.

DFM Principles 2: Design

A well-designed product is easy to manufacture, assemble, and inspect. Simplifying part geometry, minimizing part count, and incorporating self-locating features can significantly reduce assembly time and costs. For example, Apple’s MacBook unibody aluminum chassis integrates multiple components into a single piece, reducing part count and assembly complexity. This approach not only enhances durability and aesthetics but also streamlines production.

Key Considerations for Efficient Design

- Simplify Geometry:

Use standardized shapes and avoid unnecessary complexity. This reduces manufacturing challenges and inspection time. - Minimize Part Count:

Combine features into a single part. For instance, snap-fit joints eliminate screws, reducing assembly steps and components. - Self-Locating Features:

Tabs, slots, or alignment pins ensure parts fit together correctly without additional tools. - Realistic Tolerances:

Balance precision with manufacturability—overly tight tolerances increase costs without adding value. - Error-Proofing (Poka-Yoke):

Design asymmetrical features (e.g., unique screw holes) to prevent incorrect assembly.

Adopting Design for Assembly (DFA) principles is critical. Aim for assemblies with fewer than 10 parts to reduce labor and potential failure points. Avoid over-engineering by focusing on core functionality—strip away features that don’t add value. Early prototyping is essential; test designs to validate assembly processes and identify improvements before full-scale production. For example, 3D-printed prototypes can reveal misalignments or fit issues that are costly to fix later.

DFM Principles 3: Material

Material selection is a cornerstone of DFM principles, ensuring products meet functional requirements while being cost-effective and easy to process. For example, polypropylene is widely used in injection molding due to its low cost, durability, and excellent flow properties, making it ideal for thin-walled parts. Similarly, aluminum’s machinability and strength make it a go-to choice for CNC-machined components.

According to a Grand View Research report, the global plastics market is projected to grow by 4.2% annually, driven by demand for lightweight, cost-effective materials. However, sustainability is now a key driver—recyclable or biodegradable materials like PLA (used in 3D printing) are gaining traction to meet environmental regulations and consumer expectations.

Key Considerations

- Material Properties:

Match mechanical, thermal, and chemical properties to the product’s use. For example, stainless steel offers corrosion resistance for medical tools, while ABS provides impact resistance for automotive parts. - Manufacturability:

Ensure compatibility with the chosen process. High-flow plastics (e.g., polypropylene) suit injection molding, while machinable metals (e.g., aluminum) work for CNC. - Cost and Availability:

Opt for readily available materials to avoid delays. For instance, PLA is affordable for prototyping, while aerospace-grade titanium is costly and niche. - Sustainability:

Prioritize recyclable or biodegradable options. For example, TPU (thermoplastic polyurethane) is reusable in 3D printing, reducing waste.

Always align materials with the manufacturing process. Avoid brittle materials like some ceramics in CNC machining, as they may crack during cutting. Test materials rigorously—conduct stress tests for load-bearing parts or thermal tests for high-temperature environments. For sustainable solutions, explore bio-based polymers or recycled composites, which balance performance and eco-friendliness.

Generally, our engineer suggests:

- Injection Molding: Polypropylene and ABS for high-volume, thin-walled parts.

- CNC Machining: Aluminum for precision components, stainless steel for durability.

- Additive Manufacturing: PLA for prototypes, nylon and TPU for functional parts.

DFM Principles 4: Environmental Resilience

This principle ensures products perform reliably throughout their lifecycle—from manufacturing and use to disposal. Whether in a scorching industrial plant or a humid outdoor setting, environmental resilience is key to longevity and reduced failure risks. For example, automotive manufacturers use heat-resistant alloys and protective coatings on engine components to endure extreme temperatures and corrosion. Similarly, electronic enclosures are designed with heat-resistant materials and ventilation to prevent overheating, ensuring reliability in demanding conditions.

Key Considerations for Environmental Resilience

- Manufacturing Environment:

Design parts that align with existing facilities and equipment. Avoid designs requiring specialized tools or conditions unless justified by critical needs. - Operational Environment:

Tailor materials and features to withstand temperature swings, humidity, vibration, or chemical exposure. For instance, stainless steel resists corrosion in marine environments, while silicone seals protect electronics from moisture. - End-of-Life Sustainability:

Prioritize recyclability or biodegradability. For example, modular smartphones allow easy disassembly for recycling components like batteries and screens. - Energy Efficiency:

Optimize designs to reduce energy use during production and operation. Lightweight materials in automotive parts, for instance, lower fuel consumption.

In real-world applications, thermal management is critical for products exposed to high temperatures. Heat-resistant plastics or integrated cooling fins in electronics prevent overheating, ensuring reliable performance. For corrosive environments, materials like stainless steel or protective coatings such as powder coating or anodizing are essential to extend product life. Additionally, sealed enclosures with IP67 ratings are commonly used in outdoor IoT devices to shield sensitive components from dust and water.

Simulate real-world conditions early using environmental testing chambers—exposing prototypes to extreme temperatures, humidity, or vibration uncovers flaws before mass production. For durability, incorporate features like shock-absorbing materials in ruggedized devices or reinforced corners in industrial equipment. Always design with end-of-life in mind: use standardized screws for easy disassembly or mark recyclable materials for efficient sorting.

By embedding environmental resilience into your design, you create products that last longer, perform better, and align with sustainability goals. Partnering with experts in materials science or environmental testing can further refine your approach, ensuring your product thrives in any setting.

DFM Principles 5: Compliance/Testing

This design for manufacturing principle ensures products meet all regulatory standards, industry requirements, and quality benchmarks through rigorous testing and validation. Compliance guarantees safety and legality, while testing validates performance and durability. For example, the medical device industry must adhere to strict FDA regulations. Companies that integrate compliance and testing early in the design phase avoid costly recalls and delays—a single product recall can cost up to $8 million, according to industry estimates.

Key Strategies for Compliance and Testing

- Regulatory Compliance:

Design products to meet relevant standards such as ISO (quality management), RoHS (restriction of hazardous substances), or FDA (medical devices). For instance, consumer electronics sold in the EU must comply with RoHS to limit toxic materials like lead or mercury. - Testing and Validation:

Conduct stress tests (e.g., cyclic load testing), drop tests, and environmental exposure tests to ensure reliability. Automotive companies, for example, test components under extreme temperatures to simulate decades of use. - Documentation:

Maintain detailed records of design decisions, material certifications, and test results. Traceability is critical—automotive manufacturers use serialized part tracking to address defects quickly. - Reliability:

Design for robustness to ensure consistent performance under expected conditions. For example, aerospace components undergo fatigue testing to prevent in-flight failures.

In the medical industry, compliance with FDA standards requires rigorous biocompatibility testing and sterilization validation. Devices like pacemakers undergo thousands of hours of simulated use to ensure reliability. Similarly, consumer electronics brands use accelerated life testing to mimic years of wear in weeks, identifying potential failures before products reach the market.

Integrate testing early in the design process. Tools like finite element analysis (FEA) simulations or rapid prototyping with 3D-printed models can uncover flaws before mass production. Partner with regulatory consultants or certified testing labs—experts can navigate complex standards like ISO 13485 for medical devices or IEC 60601 for electrical safety. Finally, treat testing as a feedback loop: use results to refine designs iteratively. Toyota’s “Kaizen” approach, for instance, relies on continuous improvement through testing insights to enhance product quality.

Design for Manufacturing is not just a set of guidelines—it’s a mindset that ensures your product is designed with manufacturing efficiency, cost-effectiveness, and quality in mind. By applying the five DFM principles—Process, Design, Material, Environment, and Compliance/Testing—you can create products that stand out in the market while minimizing risks and maximizing ROI. For complex projects, collaborating with experienced engineers can help refine your design, ensuring your project thrives in any setting.

If you’re looking to optimize your product design or need expert guidance on implementing DFM principles, reaching out to a professional custom manufacturer with experience can make all the difference.