What is Compression Molding?

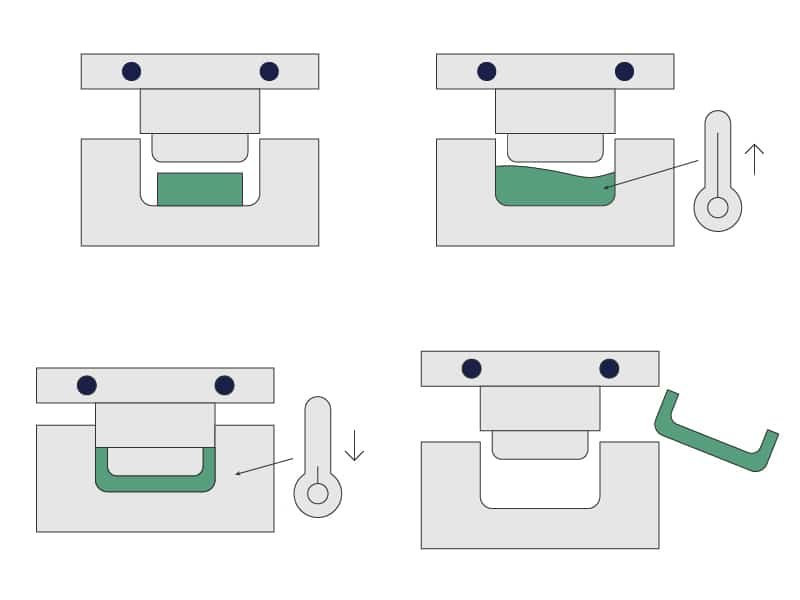

Compression molding is a widely used manufacturing process in which a pre-measured charge of material—typically a thermoset, rubber, or composite—is placed into an open, heated mold cavity. Once positioned, the mold halves (or platens) are closed and subjected to pressure and heat, causing the material to flow, conform to the mold shape, chemically cure, and solidify into the final form.

What sets compression molding apart is its strength in shaping large, high-strength parts with relatively simple geometries. It excels in forming components like gaskets, panels, seals, and electrical housings—especially those that are too big or thick for other molding processes.

This method is particularly advantageous when working with expensive or specialized materials, as it minimizes waste—any excess (known as flash) can be trimmed and reused. Additionally, the tooling is typically simpler and less costly compared to injection or transfer molding, making compression molding an economical choice for both low- to medium-volume production and prototyping

A Brief History and Evolution of Compression Molding

Compression molding has its origins in the early 20th century, when rubber was the primary material used. The process evolved significantly with advancements in material science, particularly with the advent of thermosets and composites in the latter half of the century. Modern compression molding technology has embraced automation and smart systems, making the process faster, more reliable, and environmentally friendly.

How Compression Molding Works

Step-by-Step Process of Compression Molding

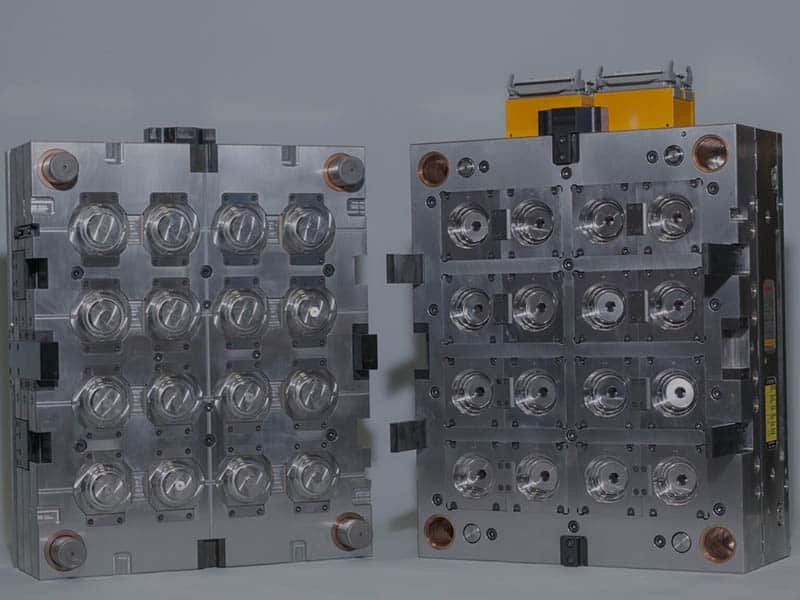

- Mold Preparation and Setup: Molds are typically machined from steel or aluminum using methods such as CNC machining. Once ready, they are mounted in a high-tonnage hydraulic press. The mold surfaces are cleaned, and the press is calibrated for precise temperature and pressure control.

- Material Loading (Charge Placement): The material is carefully measured and positioned in the center of the mold’s cavity. Precise measurement is essential: too much material creates excessive flash, while too little leads to incomplete filling.

- Compression, Heat, and Cure: Once the mold halves are closed, heat and pressure are applied simultaneously. Heat serves to soften or activate chemical curing in the material, while pressure forces it fully into the mold’s geometry.

- Opening the Mold and Ejection: Following the cure cycle, the mold is opened. Parts are then ejected using manual tools or automated systems such as ejector pins or pushers—depending on part complexity and production volume.

- Trimming (Removing Flash) and Finishing: Compression molding often results in thin, excess material along the parting line—known as flash. This is manually trimmed or removed via automated processes like cryogenic deflashing. The part may also undergo cleaning and light finishing operations to ensure it meets specifications.

Key Components in Compression Molding: Machines and Tools

The essential machinery for compression molding includes the mold press, heating elements, and cooling systems. The mold press applies the pressure needed to shape the material, while heating elements regulate the temperature to ensure the material is sufficiently soft. Cooling systems are employed to solidify the material after molding, ensuring a high-quality, durable product.

Types of Compression Molding

Compression molding is a highly versatile technique that can be tailored to meet the specific demands of various industries. From traditional methods to advanced innovations, the type of compression molding process chosen will depend on factors such as material properties, product design complexity, and production volume. This section explores the different types of compression molding, providing insights into how each variation serves distinct manufacturing needs.

Rubber Compression Molding

Rubber compression molding is one of the most common applications of the compression molding process. It is primarily used for producing components like seals, gaskets, and rubber-based parts that require flexibility, resilience, and durability. Rubber, whether natural or synthetic, has excellent material properties, including high elasticity and wear resistance, making it ideal for applications in industries such as automotive, medical devices, and industrial machinery.

The rubber compression molding process is highly straightforward. A rubber compound, typically in the form of a pre-measured, uncured rubber blank, is placed in the mold. The mold is then closed, and heat and pressure are applied to cure the material into the desired shape. The key to producing high-quality rubber parts lies in maintaining precise temperature and pressure controls, ensuring that the rubber cures evenly without defects like air pockets or uneven vulcanization.

Plastic Compression Molding

Plastic compression molding is also a manufacturing process for producing high-strength, lightweight plastic parts in industries ranging from automotive to consumer goods. This process is especially suitable for molding thermosetting plastics, which, once cured, become permanently hardened and resistant to deformation under heat. In plastic compression molding, a preheated charge of thermoset material is placed into the mold cavity, where heat and pressure cause the material to flow and harden into the desired shape.

Plastic compression molding is ideal for producing parts with consistent quality and precision, including electrical insulators, automotive components, and appliance parts. PTFE compression molding and UHMW compression molding are commonly used due to their excellent electrical insulating properties and high resistance to heat and chemical corrosion.

Thermoset Compression Molding

Thermoset compression molding refers to the use of thermosetting materials, which undergo a chemical reaction during the molding process to form a rigid, durable part. Once thermosets are cured, they cannot be reheated or reshaped, making them ideal for applications requiring high strength and stability under harsh conditions. Popular thermoset materials used in this process include phenolic, epoxy, and melamine resins.

Thermoset compression molding is particularly advantageous in industries such as automotive, aerospace, and electrical equipment, where parts need to withstand extreme temperatures, pressures, and chemical exposure. The key benefit of thermoset compression molding lies in the enhanced durability and dimensional stability of the molded parts, which often require minimal post-molding processing.

Advanced Compression Molding Techniques

Advanced compression molding techniques, on the other hand, offer increased precision, efficiency, and versatility. Techniques such as high-pressure compression molding, transfer molding, and automation have significantly enhanced the process. These methods not only reduce cycle times but also enable the production of more complex shapes with greater accuracy. Advanced compression molding technologies can also accommodate the integration of inserts and the use of hybrid materials, pushing the boundaries of what is possible in part design and functionality.

As manufacturing technology advances, so too do the methods and tools used in compression molding. Here are some of the latest developments in the field.

- Automation in Compression Molding: Providing manufacturers with a range of benefits that include higher consistency, reduced labor costs, and faster production cycles. Automated systems are able to perform repetitive tasks such as loading the mold, monitoring the temperature and pressure, and even inspecting parts after they have been ejected from the mold. Automated systems also allow for better use of energy and materials, making the process more cost-effective and environmentally friendly.

- Compression Molding with Inserts and Inserts Molding: Inserts molding is a process that involves placing pre-formed materials, such as metals or plastics, into the mold before the molding material is applied. The insert becomes embedded into the molded part, providing additional functionality like electrical conductivity or mechanical reinforcement.

Read Insert Molding Manufacturing and Design Guide.

Materials Used in Compression Molding

One of the key advantages of compression molding is its ability to process a wide range of materials, from rubber and elastomers to thermoplastics and composite materials. Each material has unique properties that make it suitable for specific applications. This section delves into the different materials commonly used in compression molding, highlighting their characteristics and benefits.

Rubber and Elastomers in Compression Molding

Rubber and elastomers are the primary materials used in compression molding for applications requiring flexibility, resilience, and wear resistance. Natural rubber, synthetic rubber, and elastomers like silicone are frequently molded in this process. These materials are ideal for producing seals, gaskets, o-rings, and other components that must maintain their shape under compression or stretching. Here are the common rubber material for compression molding,

- MVQ/Silicone

- EPDM (Ethylene Propylene Diene Monomer)

- NR (Natural Rubber)

- NBR (Nitrile Butadiene Rubber)

- CR/Neoprene (Chloroprene Rubber)

- SBR (Styrene-Butadiene Rubber)

- IIR/Butyl (Isobutylene isoprene rubber)

- FKM (Fluoroelastomer)

- FFKM (Perfluoroelastomer)

Thermoplastic Materials in Compression Molding

Thermoplastic materials, unlike thermosets, can be reheated and remolded, making them more versatile for certain applications. Materials such as PTFE and UHMWPE are commonly used in compression molding to create durable and lightweight components. Thermoplastics are particularly valued for their ease of processing, cost-effectiveness, and recyclability.

Compression molding thermoplastic materials allows for the production of high-strength, high-impact components that are used in various industries, including automotive, electrical, and consumer goods. The molding process requires careful temperature control to ensure the material flows evenly into the mold, resulting in parts with consistent mechanical properties.

Composites and Hybrid Materials for Compression Molding

The use of composite materials in compression molding has grown significantly due to the demand for stronger, lighter parts that can withstand extreme conditions. Composite materials combine two or more distinct materials—such as fibers and resins—to achieve enhanced mechanical properties. Common composites used in compression molding include glass fiber-reinforced plastics (GFRP) and carbon fiber-reinforced plastics (CFRP).

Hybrid materials, which combine the benefits of thermoplastics and thermosets or rubber, are also gaining popularity in compression molding. These materials offer improved performance, strength, and durability, especially in applications where high mechanical loads and resistance to environmental factors are required.

Mold Design and Development

Mold design plays a crucial role in determining the quality and functionality of the final molded part. The efficiency of the molding process, the strength of the parts, and the overall cost of production all depend on the mold design. This section explores the critical elements of mold design and development, providing key insights into how to achieve optimal results in compression molding.

Choose the Right Mold Material

Selecting the appropriate mold material is foundational to tool life and performance. Here are the common tooling materials for compression molding.

- P20 steel: Offers a cost-effective balance for medium-volume runs.

- Hardened steel: Ideal for high-volume production—exceptional durability but higher cost and longer lead times.

- Aluminum: Best suited for prototypes or pilot molds where wear is minimal.

Account for Press Capacity and Compression Ratio

Compression molds endure high tonnage and must be designed to withstand press tonnage without distortion. Calculating the correct compression ratio ensures the material is adequately compacted for proper cure and density. Ignoring this aspect can lead to underfilled parts or excess deformation.

Plan for Flash Control and Parting Lines

Flash—excess material squeezed out at mold seams—is a common defect in compression molding. Strategic placement of parting lines—preferably in low-visibility or low-stress areas—and mold features that simplify flash trimming are essential for cleanliness and efficiency.

Compensate for Shrinkage and Thermal Expansion

Materials undergo dimensional changes as they cure and cool. Accounting for shrinkage—and, in precise applications, compensating for mold material thermal expansion—is critical to achieve dimensional precision. Careful calculation ensures parts meet spec even after cooling.

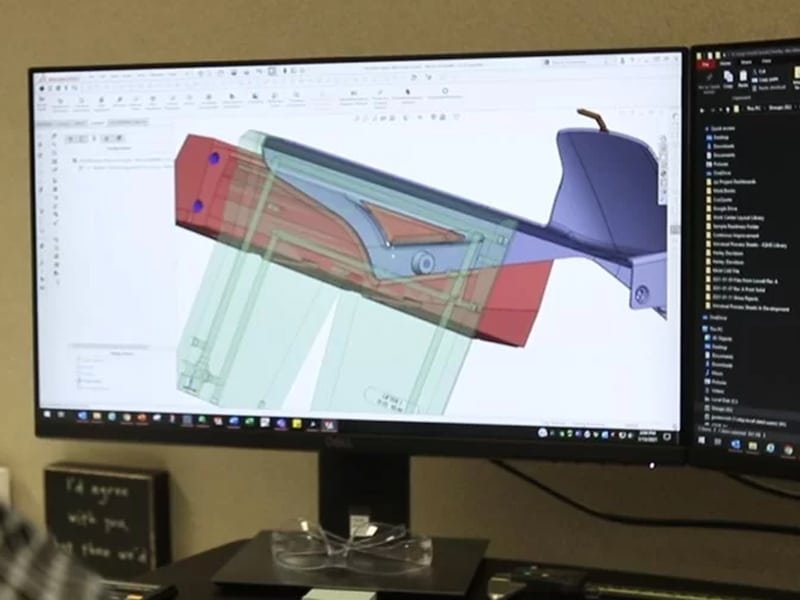

Adapt Designing for Manufacturability and Simulation Tools

When designing molds for compression molding, manufacturability must always be considered. This involves designing molds that not only produce high-quality parts but also minimize the time and cost required for production. One of the most important considerations in manufacturability is the ease of part ejection. Components that are difficult to remove from the mold often lead to delays and potential damage, which can increase production costs.

The material flow within the mold is another critical factor. The design should allow the material to fill the cavity uniformly to avoid defects. Additionally, optimizing cooling and heating systems within the mold ensures that parts cure uniformly, leading to better consistency and performance.

Factors Affecting Compression Molding Products’ Quality

Compression molding is a precise manufacturing process influenced by several key factors that directly impact the quality, efficiency, and cost of the final product. Understanding and optimizing these factors are essential to ensuring high-quality parts, cost-effectiveness, and minimized production downtime. The following section discusses the critical elements that affect compression molding and how to manage them for optimal results.

Temperature Control

Temperature is one of the most critical factors in compression molding. Both the mold and the material must be maintained at the correct temperatures to achieve the desired material flow and part properties. If the temperature is too high or too low, it can result in defects such as incomplete filling, warping, or poor part quality.

Proper temperature control helps regulate the curing process, ensuring the material is properly vulcanized (in the case of thermosets) or properly solidified (in thermoplastics). It also influences cycle time, as the material needs sufficient time to heat and cure within the mold. Automated temperature regulation systems are often used to monitor and adjust mold and material temperatures, ensuring the process remains consistent and efficient.

Pressure Application

Pressure plays a pivotal role in determining the final properties of the molded part. The application of pressure forces the material into the mold cavity, ensuring that it fills the mold entirely and evenly. In compression molding, too much pressure can cause excessive flow, leading to material overflow or flash, while too little pressure may result in incomplete part formation.

Achieving the right balance of pressure is crucial for ensuring the material flows correctly, filling all sections of the mold without creating voids or inconsistencies. Proper pressure application also impacts material compaction, which can affect part strength and durability. High-pressure molding techniques are often used when manufacturing high-performance parts that require exceptional strength and dimensional stability.

Curing Time

Curing time is the amount of time the material must remain under heat and pressure to achieve its desired properties. This time is critical to ensuring the material undergoes the necessary chemical reactions to achieve full solidification and structural integrity. If curing time is too short, the material may not fully cure, resulting in parts that are weak or poorly formed.

On the other hand, excessive curing time can lead to overcooking the material, causing degradation or unwanted changes in its properties. Managing curing time effectively helps to optimize cycle time, reduce defects, and enhance the final part’s quality. Monitoring curing time is especially crucial when dealing with thermoset materials, which require precise curing to maintain their rigidity and durability.

Material Consistency

Material consistency is a fundamental aspect of the compression molding process. Variations in material properties, such as viscosity, filler content, or batch quality, can have significant effects on part quality. Inconsistent materials may not flow uniformly into the mold, leading to uneven parts, air pockets, or weak points.

Ensuring material consistency requires tight quality control over raw material suppliers, batch testing, and handling practices. Manufacturers must also ensure that the material is homogeneously mixed and free from contaminants to avoid any potential defects during molding. Consistent material quality leads to higher yields, fewer defects, and more predictable part performance.

Cycle Time

Cycle time refers to the total time it takes to complete one molding cycle, from placing the material in the mold to ejecting the finished part. Minimizing cycle time is crucial for improving manufacturing efficiency, reducing labor costs, and increasing throughput. However, reducing cycle time should not come at the cost of part quality.

Optimizing cycle time involves balancing the curing process, temperature control, and pressure application to ensure that parts are molded quickly yet accurately. Shorter cycle times are often possible with advanced molding techniques, automation, or optimized mold designs, which streamline material flow and improve heating/cooling efficiency.

Cost Considerations in Compression Molding

While compression molding offers several advantages, including versatility and low material waste, it is essential to understand the associated costs to ensure profitability. From tooling and setup to material selection, various cost factors must be balanced to maintain cost-effectiveness in the manufacturing process.

Cost-Effective Strategies for Compression Molding

One of the most effective ways to reduce costs in compression molding is through efficient mold design. A well-designed mold reduces material waste and minimizes the number of defective parts, improving both the production process and overall yield. Additionally, optimizing material choice to suit the part’s requirements can lower material costs without sacrificing performance.

Other cost-saving strategies include adopting automation and robotic systems for material handling, part removal, and mold maintenance. These systems help improve efficiency, reduce labor costs, and minimize human error. Effective process monitoring systems that automatically adjust temperature, pressure, and curing time also contribute to cost savings by optimizing resource use.

Understanding Tooling and Setup Costs

Tooling costs in compression molding are significant, especially for highly customized molds. The complexity of the mold design, the material selected, and the expected production volume all influence tooling expenses. For example, molds made from high-strength steel or aluminum require substantial investment but offer long-term durability for high-volume production runs.

Setup costs can also be considerable, as adjusting molds and equipment for each new batch or material requires time and labor. These costs must be factored into overall production costs, particularly for shorter production runs or prototype manufacturing. Strategies to reduce tooling and setup costs include designing molds for flexibility and ease of adjustment, allowing manufacturers to switch between different materials or part designs with minimal downtime.

Material Costs and Their Impact on Production

The choice of material significantly impacts both the initial cost and long-term production expenses. While high-performance materials such as composites or specialized elastomers can enhance product performance, they often come at a higher cost. Conversely, lower-cost materials like standard thermoplastics may offer lower performance but can be more cost-effective for mass production.

The cost of materials can fluctuate depending on factors like market demand, availability, and material quality. Manufacturers must continuously monitor material costs and adjust their sourcing strategies to maintain profitability. Additionally, material efficiency plays a role in managing production costs—minimizing waste and optimizing material usage can significantly reduce overall material expenses.

Optimizing the Balance Between Production Speed and Cost

Compression molding allows for the production of high-quality parts, but optimizing the balance between production speed and cost requires careful planning. Faster production often leads to higher costs due to factors like increased energy use, faster wear on tooling, and more frequent mold changes. On the other hand, focusing on cost-efficiency may extend production time, affecting output and profitability.

Balancing production speed and cost requires evaluating the most cost-effective way to manufacture each part without sacrificing quality or consistency. Process optimization techniques, including automation, mold design, and material selection, can help improve production rates while maintaining cost-effectiveness.

Benefits of Compression Molding

Compression molding offers several advantages, especially for manufacturers seeking high-quality, cost-effective production solutions. It is especially well-suited for creating parts that require durability, flexibility, and complex geometries. Understanding these benefits can help manufacturers determine whether this method is the right choice for their production needs.

Cost-Effectiveness for Low to Medium Volume Production

One of the key benefits of compression molding is its cost-effectiveness, particularly for low to medium volume production. While the initial mold creation can be more expensive compared to other methods like injection molding, the relatively low operational costs and reduced cycle times make it an affordable choice for small- to medium-sized production runs.

Compression molding also eliminates the need for intricate tool adjustments between runs, which makes it suitable for runs where customization and rapid changes are necessary. Furthermore, because the process requires fewer components and simpler machinery, overall manufacturing expenses are kept low, especially when compared to more complex molding techniques.

Ability to Create Complex Geometries

Compression molding excels at producing complex geometries and detailed features within molded parts. The process allows manufacturers to mold intricate designs that might be difficult or impossible to achieve with other molding methods.

This capability is particularly useful for industries such as automotive and aerospace, where components must meet strict design specifications while maintaining high strength and durability. The process can also create multi-material parts, enabling the combination of different properties in a single part, such as reinforced plastics or rubber embedded with metal inserts.

Durability and Strength of Compression Molded Parts

Compression molding is renowned for producing parts that are both strong and durable. The application of high pressure during the molding process results in parts that have excellent mechanical properties, making them suitable for demanding applications in industries like automotive, medical devices, and heavy machinery.

The parts produced through compression molding have higher impact resistance and wear resistance, which makes them ideal for use in environments subject to heavy stress and wear. The uniform density of parts produced in this method contributes to their overall strength and long-lasting durability.

Reduced Material Waste and Increased Efficiency

Material waste is minimized in compression molding due to the precise amount of material that is used in each molding cycle. The excess material is typically removed after the molding process and can often be recycled or reused in subsequent production runs. This material efficiency not only helps reduce waste but also lowers production costs.

The molding process itself is efficient, with a relatively short cycle time for many parts, especially in comparison to methods such as injection molding. Manufacturers can produce high-quality parts at a faster rate, thereby improving overall throughput and ensuring that production stays on track.

Low Energy Consumption Compared to Other Molding Methods

Another significant benefit of compression molding is its relatively low energy consumption. Because compression molding does not require the same level of energy input as injection molding or other more energy-intensive processes, it is a more environmentally friendly option.

The method involves heating the material only until it is soft enough to flow into the mold, which results in lower energy usage compared to the continuous heating required in methods like injection molding. As manufacturers strive for greener practices, compression molding provides an effective way to reduce energy consumption and operational costs.

Challenges and Limitations of Compression Molding

While compression molding has many advantages, there are several challenges and limitations to consider when choosing this process for manufacturing.

Longer Cycle Times Compared to Injection Molding

One of the main drawbacks of compression molding is that the cycle times are generally longer than those of injection molding. Compression molding requires longer heating times and higher pressures, which can result in slower production rates.

This can be a significant factor if high-speed manufacturing is critical, as in industries like electronics or consumer goods, where injection molding may be preferred for its speed and efficiency. However, the slower cycle time can be mitigated by optimizing other factors like mold design and process automation.

Material Handling and Consistency Issues

Compression molding requires precise material handling to ensure consistent part quality. Variations in material quality, such as inconsistent viscosity or improper material amounts, can lead to defects such as air pockets or inconsistent thickness in the molded parts.

Maintaining consistency throughout the production run can be a challenge, particularly with thermoset materials, which may exhibit thermal expansion and shrinkage during the curing process. Ensuring that materials are properly mixed and handled is key to achieving optimal results.

Mold Maintenance and Its Impact on Production

Maintaining the molds used in compression molding is critical to ensuring consistent part quality and preventing breakdowns during production. Mold wear, especially in high-volume production environments, can result in defects or even downtime if not regularly maintained.

Mold maintenance involves cleaning, lubricating, and sometimes repairing the molds to ensure that they perform consistently across long production runs. Regular mold inspection and maintenance programs are essential to minimize production disruptions and maximize mold lifespan.

Common Applications of Compression Molding

Compression molding is used across many industries due to its ability to produce durable, high-performance parts in a cost-effective manner. The process is particularly favored for components that require high strength, intricate details, or specialized material properties.

Automotive Industry: High-Performance Parts and Seals

In the automotive industry, compression molding is commonly used to create high-performance parts, such as seals, gaskets, and bushings. These components require excellent durability, resistance to heat, and the ability to withstand harsh operating conditions. Rubber and thermoplastic materials are often used for automotive components, offering properties such as flexibility, vibration dampening, and resistance to oils and chemicals.

Compression molding’s ability to produce parts with tight tolerances and complex geometries makes it ideal for automotive manufacturing. Additionally, the process allows for cost-effective production of both low-volume and high-volume components, meeting the demands of both prototype development and mass production.

Consumer Goods: Durability and Cost-Effectiveness

Compression molding is also widely used in the production of consumer goods, where durability, cost-effectiveness, and material versatility are essential. Items such as kitchen appliances, tools, and household products benefit from compression molding’s ability to create parts with intricate designs and high strength.

The versatility of materials, such as plastics, rubber, and composites, allows manufacturers to select the ideal material for each product, balancing performance requirements with cost constraints. Whether creating durable handles for kitchen appliances or protective cases for electronics, compression molding provides a reliable and efficient solution.

Medical and Healthcare: Precision Components and Safety

In medical device manufacturing, compression molding is used to create components that require both precision and safety. Parts such as seals, gaskets, and housings must meet stringent safety and regulatory standards. Compression molding provides the necessary precision to ensure that these parts perform reliably in medical environments.

The use of rubber, elastomers, and medical-grade plastics in compression molding allows manufacturers to create parts that are biocompatible, durable, and able to withstand sterilization processes. The ability to mold complex shapes and precise tolerances ensures the safety and functionality of medical devices.

Aerospace Industry: Lightweight, High-Strength Parts

Aerospace applications demand lightweight, high-strength parts that can endure extreme temperatures and stresses. Compression molding’s ability to process materials like carbon fiber-reinforced plastics (CFRP) and other composite materials makes it ideal for producing aerospace components such as brackets, seals, and insulation.

The high strength-to-weight ratio of compression-molded composite materials ensures that aerospace parts meet performance specifications without adding unnecessary weight. These parts must also withstand high temperatures, making material selection and curing time crucial factors in ensuring long-term performance.

Electrical and Electronics: Insulation and Conductivity

In the electrical and electronics industries, compression molding is often used to produce parts that provide insulation, conductivity, or both. Components such as connectors, insulators, and switches are commonly made using this technique, especially when the parts require consistent material properties and electrical performance.

Compression molding is particularly useful for molding thermoplastic materials, such as polycarbonate and nylon, which offer excellent electrical insulation properties. The ability to create parts with precise dimensions ensures that electrical components fit together securely and perform reliably in their respective devices.

Advanced Compression Molding Techniques

As manufacturing technology advances, so too do the methods and tools used in compression molding. Here are some of the latest developments in the field.

Transfer Molding vs. Compression Molding

Transfer molding is often compared to compression molding, as both are used to produce highly intricate parts. The primary difference lies in how the material is introduced into the mold. In transfer molding, material is placed in a pot, and pressure forces it through a runner system into the mold cavity. This technique is often used for smaller parts or parts with finer details, while compression molding is typically used for larger or thicker parts.

The decision to use transfer molding or compression molding depends on factors such as part design, material characteristics, and production volume.

Automation in Compression Molding

Automation is transforming the landscape of compression molding, providing manufacturers with a range of benefits that include higher consistency, reduced labor costs, and faster production cycles.

Automated systems are able to perform repetitive tasks such as loading the mold, monitoring the temperature and pressure, and even inspecting parts after they have been ejected from the mold. This allows for real-time adjustments to be made to the molding process, which improves overall part quality and reduces defects. Automated systems also allow for better use of energy and materials, making the process more cost-effective and environmentally friendly.

Compression Molding with Inserts and Inserts Molding

Insert molding is a process that involves placing pre-formed materials, such as metals or plastics, into the mold before the molding material is applied. The insert becomes embedded into the molded part, providing additional functionality like electrical conductivity or mechanical reinforcement.

This technique is frequently used in industries like automotive, where parts often require integrated components like metal fasteners, threads, or reinforced structures. The key to successful insert molding is ensuring that the insert is securely placed in the mold before the compression molding process begins to ensure a strong bond between the insert and the surrounding material.

Integrating Additive Manufacturing with Compression Molding

Additive manufacturing, or 3D printing, is being integrated into compression molding to allow for the creation of highly intricate molds with complex geometries. 3D printed molds are quicker and cheaper to produce than traditional molds and can be customized to meet specific production needs.

This synergy between additive manufacturing and compression molding offers manufacturers the opportunity to reduce mold costs, shorten lead times, and create highly customized parts for low to medium volume production.

The Use of Smart Sensors for Process Control and Monitoring

The integration of smart sensors into the compression molding process provides manufacturers with real-time data on key variables such as temperature, pressure, and cycle time. These sensors enable automated feedback loops, allowing the system to adjust parameters and ensure that the molding process is optimized for part quality.

Smart sensors can also help detect any abnormalities in the process, such as overheating or underpressure, which can lead to defects. This enhances overall process control, reduces the need for manual interventions, and ensures a higher level of consistency across the production run.

Quality Control in Compression Molding

Ensuring high-quality outputs in compression molding requires rigorous quality control measures at each stage of the process. From material selection to post-production inspection, quality assurance is vital to maintaining consistency and durability across all molded parts.

Importance of Quality Assurance for Consistency and Durability

Quality assurance (QA) in compression molding ensures that the finished parts meet both aesthetic and functional standards. Consistency is key to producing reliable parts, especially when the molding process involves intricate designs or materials with strict performance requirements. QA procedures help monitor and regulate key process variables such as temperature, pressure, and curing time, ensuring that each cycle produces identical results.

Durability is another critical factor, particularly in industries like automotive, aerospace, and medical devices, where parts must withstand harsh conditions. Effective QA practices ensure that each molded component retains its structural integrity, performance capabilities, and longevity throughout its lifecycle.

Visual Inspections and Automated Quality Control Systems

Visual inspections are an essential part of quality control in compression molding. Operators manually check for defects such as flash, surface imperfections, or irregularities in part geometry. However, manual inspections can be time-consuming and prone to human error.

Automated quality control systems are increasingly used in advanced molding operations to speed up the inspection process and reduce the risk of defects slipping through unnoticed. These systems utilize cameras, sensors, and advanced software to analyze parts in real time. They can identify anomalies such as color variation, dimensional discrepancies, and surface defects with remarkable accuracy, ensuring that only the highest-quality parts are shipped out.

Measuring Part Dimensions and Tolerances

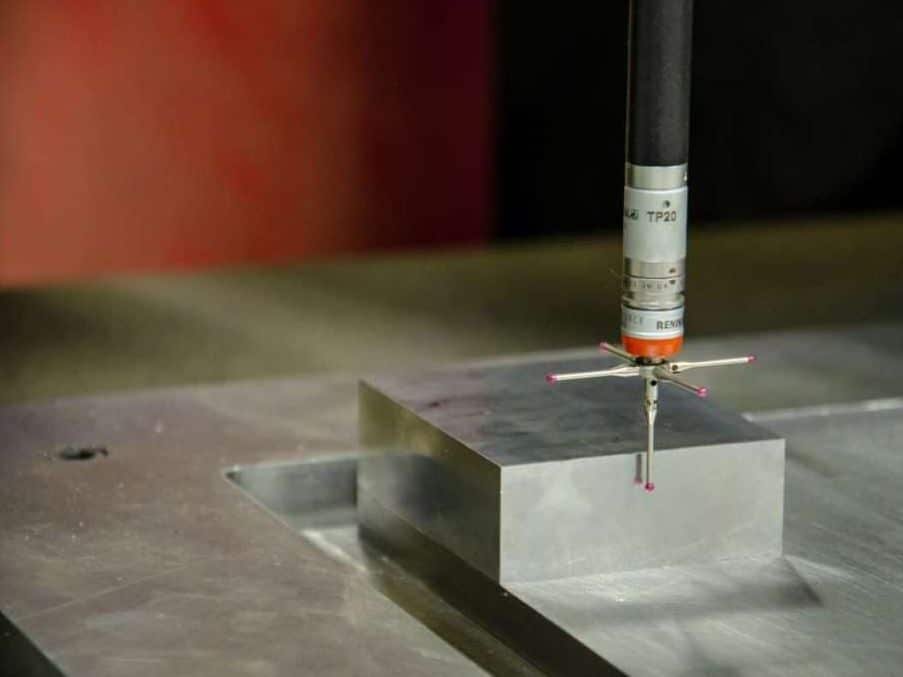

Measuring part dimensions and tolerances is an essential aspect of ensuring that molded parts fit together properly in assembly and function as intended. Compression molding typically produces parts with tight tolerances, especially in industries that require high precision, such as medical devices and electronics.

High-precision measuring tools like calipers, micrometers, and laser scanners are used to evaluate the part’s overall geometry, including wall thickness, length, and width. Computer numerical control (CNC) machines are often employed for automated measuring in high-volume production, ensuring that every part meets the required specifications without deviation.

Testing Molded Parts for Performance and Durability

Performance and durability tests are essential for evaluating how well compression-molded parts hold up under operational conditions. For instance, parts that will be exposed to heat, chemicals, or mechanical stress are subject to specialized tests, such as tensile testing, impact testing, and thermal cycling.

Tests also check for specific attributes like flexibility, elasticity, or electrical conductivity, depending on the application. In industries like aerospace and automotive, parts undergo rigorous testing to ensure they meet safety standards and can withstand extreme conditions without failure.

Common Defects in Compression Molding

Common defects in compression molding can arise from issues with material handling, mold design, process settings, or machine malfunction. Understanding these defects and implementing preventative measures is crucial for maintaining product quality.

Some of the most frequent defects include:

- Flash: Excess material that escapes from the mold, often due to excessive pressure or poor mold clamping. Proper mold design and pressure control can minimize flash.

- Incomplete Fill: When the material does not fully fill the mold cavity. This can result from insufficient pressure or improper material viscosity. Ensuring optimal temperature and pressure settings can prevent this.

- Air Traps: These occur when air becomes trapped in the mold cavity, leading to voids or weak points in the part. Ensuring proper venting and material flow paths can eliminate air traps.

- Uneven Surface Finish: A poor surface finish can result from inadequate mold maintenance or uneven material distribution. Regular cleaning and inspection of the molds can help achieve a smooth, consistent finish.

Choosing the Right Compression Molding Service Provider

Selecting the right compression molding service provider is crucial for ensuring the success of any project. The right partner can help optimize production, improve quality, and offer valuable insights into material selection, mold design, and process improvements.

Key Criteria for Selecting a Compression Molding Partner

When choosing a compression molding service provider, it’s important to evaluate several key factors:

- Experience and Expertise: The provider should have a proven track record of success with similar projects and a deep understanding of molding processes. Look for expertise in both traditional and advanced molding techniques, as well as knowledge of materials and quality control practices.

- Technology and Equipment: Evaluate the provider’s equipment inventory to ensure they have the necessary machines to handle your specific needs. Advanced molding equipment, automation, and process monitoring systems are essential for producing high-quality parts efficiently.

- Capacity and Scalability: Choose a provider that can meet your production volume needs, whether for high-volume runs or small-batch, customized parts. The provider should also be able to scale up or down depending on your future production requirements.

- Lead Times and Production Costs: Assess the provider’s ability to meet lead times while maintaining competitive pricing. Efficient production and quick turnaround times are essential to keeping projects on schedule and within budget.

Evaluating Experience and Expertise in Molding

The experience and expertise of the molding service provider are essential in achieving the desired part quality and consistency. Providers with deep industry knowledge understand how to optimize materials, design molds for manufacturability, and implement process controls to minimize defects and reduce costs. Look for providers with relevant experience in your industry, as they will be familiar with the specific requirements and standards.

Assessing Technical Capabilities and Machine Inventory

Evaluating a provider’s technical capabilities and machine inventory is critical to ensuring they can meet your production needs. The provider should have the latest molding technology, capable of handling various materials, mold designs, and production volumes. Specialized equipment such as high-precision molding machines and automated inspection systems can significantly improve part quality and reduce lead times.

Importance of Lead Times and Production Costs

Lead time and production costs are often among the most critical factors when choosing a compression molding partner. A reliable provider should be able to deliver quality parts within your desired timeframe while keeping production costs competitive.

Understanding how lead time impacts your business operations and how cost fluctuations affect your bottom line is key. It’s important to establish clear expectations with your provider and work together to optimize the molding process for both speed and cost-efficiency.

Submit Your Compression Molding Request

Compression molding continues to play a critical role in modern manufacturing. Its versatility, cost-effectiveness, and ability to produce high-quality, durable parts make it essential across industries such as automotive, medical devices, aerospace, and consumer goods.

We hope this ultimate guide to compression molding has provided you with valuable insights and a deeper understanding of the process. Whether you’re exploring new manufacturing options or refining your current approach, we trust that the information shared will help you make more informed decisions moving forward.