The custom car dashboard is one of the most important large-scale interior components in an automobile. It not only requires sufficient strength and rigidity but also needs to meet aesthetic standards and harmonize with the overall vehicle design. At the same time, it must be lightweight. To meet these goals, modern car dashboards are typically made of engineering plastics through the process of injection molding.

What Is a Car Dashboard

The car dashboard, also known as the car instrument panel, car dash panel, or car interior dashboard, is one of the most important large components in a vehicle’s interior. It houses critical controls, displays, and electronic systems while also playing a key role in the vehicle’s overall design aesthetics and structural integrity.

This case demonstrates ErYe’s expertise in the design and manufacturing of a custom car dashboard for a well-known automotive brand. As a car dashboard manufacturer, ErYe provides tailored automotive dashboard design solutions that align with client specifications.

Project Details and Product Features

- Material: The car dashboard material is PP + EPDM-TD20. The shrinkage rate was set at 0.95%. The EPDM enhances elasticity, while TD20 refers to a 20% talc added to improve rigidity.

- Size: This is a large plastic component with dimensions of 1308mm x 526mm x 476mm. The mold is a large-scale injection mold structure. Learn about our capabilities for large part injection molding.

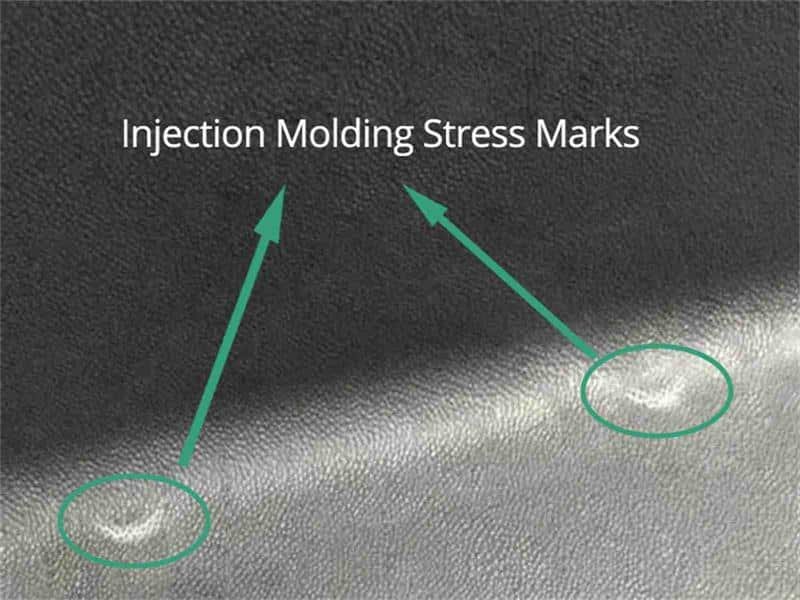

- Surface Texture: The automobile dashboard surface requires a textured leather finish. To facilitate demolding, the draft angle on the sidewalls must be ≥ 5°.

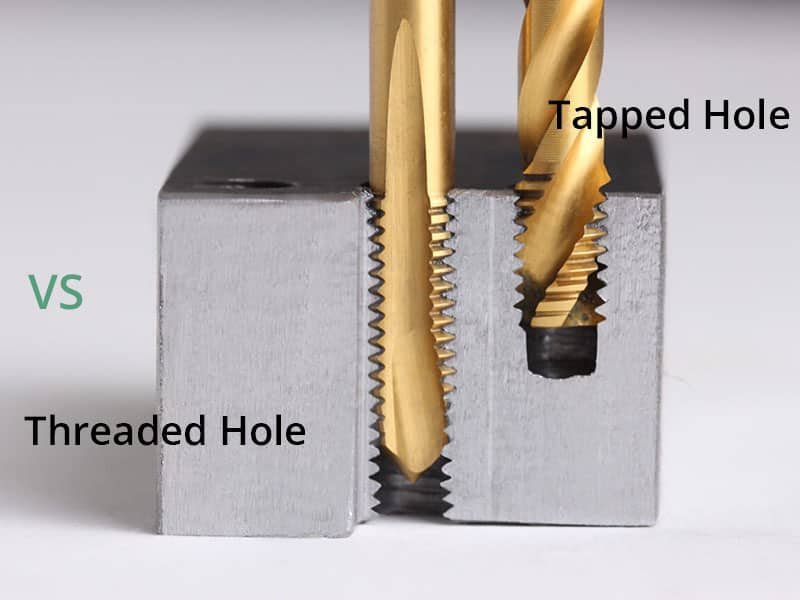

- Complex Structure: The component features complex geometry with multiple collision and penetration holes, which increases melt flow resistance. Therefore, special attention must be paid to the gate and venting system during the car dashboard design process.

- Undercuts: There are 7 irregular undercut features, which are numerous and irregular, making it difficult to demould the injection molded parts.

Car Dashboard Mold Design Process

After thoroughly understanding the client’s requirements, our engineers conducted a detailed product analysis and developed a precision mold design. The mold uses a hot runner gating system, and both the fixed and movable molds adopt an integrated original molding structure. Maximum mold dimensions: 2200 x 1100 x 1425 mm.

In the design of automobile dashboard molds, the manufacturing cost and production cost of the molds must be fully considered while ensuring the strength and life of the molds. Below is the mold design process we followed for this custom auto dashboard:

- Gating system design

- Mold forming parts design

- Side core-pulling mechanism design

- Cooling system design

- Guide and positioning system design

- Demolding system design (Explore the demolding process practical design tips)

Conclusion

This project involved a high-precision, large-sized custom automobile dashboard mold with a complex structure. Backed by our extensive experience in custom auto dashboard manufacturing, ErYe successfully delivered high-quality molded parts that fully met the customer’s expectations.

As a trusted car dashboard manufacturer, ErYe specializes in providing custom dashboard for cars, including complete car instrument panel design, mold development, and precision production. We offer one-stop solutions from car dashboard design to tooling to mass production. Whether you’re looking for a custom car dashboard solution or end-to-end dashboard molding support, Erye Molding is your reliable partner.