Rubber Injection Molding Service

We are a professional Rubber Injection Molding Factory, supplying rubber components worldwide.

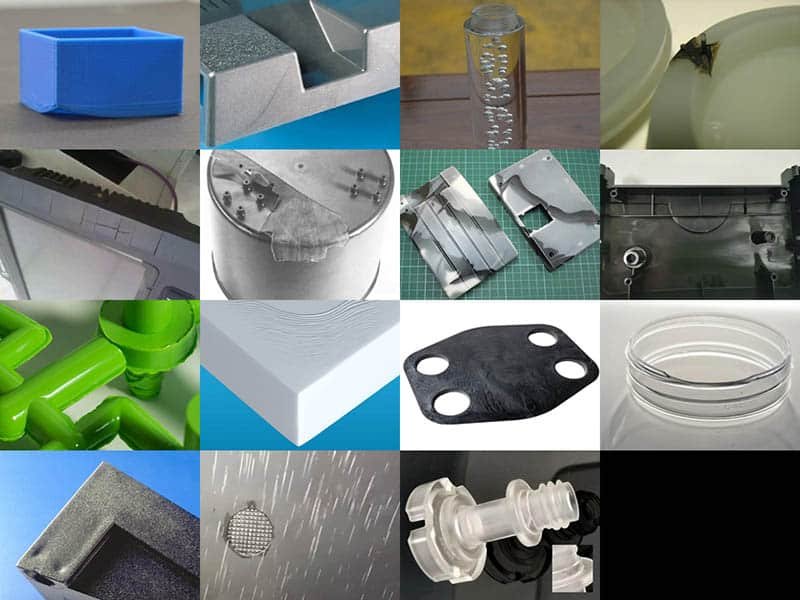

Rubber injection molding is a common manufacturing process to produce precision rubber components, especially for large-volume production. It starts with injecting heated rubber material into a pre-made mold under high pressure, then it cools and solidifies to form the desired shaped parts. The rubber injection molding is an ideal process to produce complex geometry parts with high repeatability and excellent material consistency, such as seals, gaskets, bellows, and other rubber components.

Erye has decades of experience in rubber injection molding, offering one-stop services from tooling to mass production. For every single project, our engineering team works closely with our clients to help with material selection and part design, ensuring that we meet stringent quality standards.Let's Start a Rubber Injection Molding Project

Click for Quick Guide

Step 1. Rubber Injection Molding Part Design

To start your rubber injection molding project, the first step is rubber part design. During the design stage, you need to focus on factors like part geometry, material selection, and functionality. It's essential to collaborate with experts who can help you optimize your design for both production efficiency and cost savings.

At Erye, we are willing to help you check and optimize your design to ensure part performance and manufacturability. At this stage, our engineer conducts a thorough review of your design, offers a Design for Manufacturability (DFM) report which points out potential challenges and offers optimized solutions, to ensure the design is mold-friendly and cost-effective.

Step 2. Material Selection for Injection Molded Rubber Parts

Selecting the correct and suitable material is not only to meet the basic requirements, but also to opimize performance for your product. The right material is able to reach the required lifespan and has the ability to withstand the required usage conditions.

For example, we assist our clients in making material choices based on the specific demands of their project. In some cases, To ensure special requirements in some cases, we use specialized material formula to adjust material properties, so your injection molded rubber parts deliver exactly the performance you need.Step 3. Rubber Injection Mold Design & Production

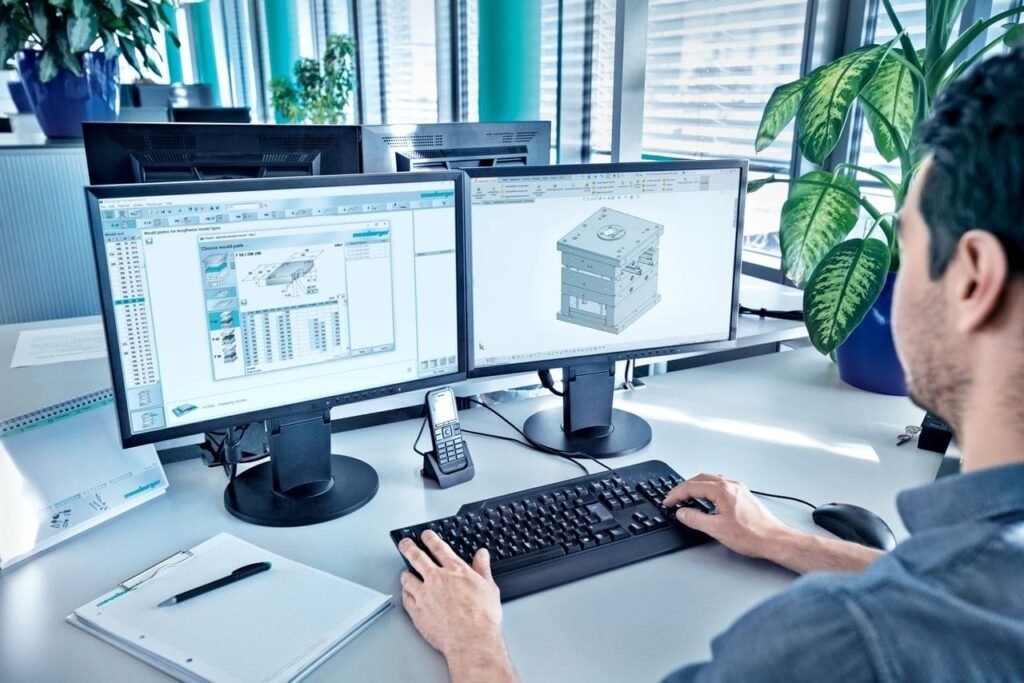

Once the part design has been finalized and confirmed the material, the next step is mold & tooling design and production. The injection molding tooling directly influences final product quality, production efficiency, and overall cost.

When design the rubber injection mold, our engineer will review the parts specifications thorougly, taking into account the design, material properties, and production volume. We simulate mold flow analysis to optimzie the mold design and avoid production issues, thereby improving production processes.

Once the mold design is finalized, our manufacturing facility produces the mold using advanced CNC machining centers, EDM, WEDM, and other advanced machines. From intricate part features to cooling channels, our expert mold makers ensure deliver molds that provide long-lasting performance.

Step 4. Mass Production of Rubber Injection Molding

Equipped with over 20 sets of advanced rubber injection molding machines, our facilities are capable to handle both small-volume and large-scale production with high precision. Over the past decades, we have produced rubber parts for various industries like automotive, medical devices, and mining, serving thousands of customers, our efficient systems and flexible scheduling ensure in-time delivery without compromising on quality.

Our automatic machines are able to offer 24/7 production to meet tight deadline demands. For example, we are able to finish 100,000pcs rubber gaskets within 2 weeks, we ensure to meet our client's high-volume demands without sacrificing quality.

Step 5. Secondary Process and Quality Inspection

Surface Finishing

Assembly

Quality Inspection

Features of Rubber Injection Molding

Advantages of Rubber Injection Molding

High Precision and Consistency

Cost-Effective for High-Volume Production

Complex Part Design Capabilities

Automation and Efficiency

Drawbacks of Rubber Injection Molding

High Initial Tooling Costs

Longer Lead Times for Tooling

Complex Mold Maintenance

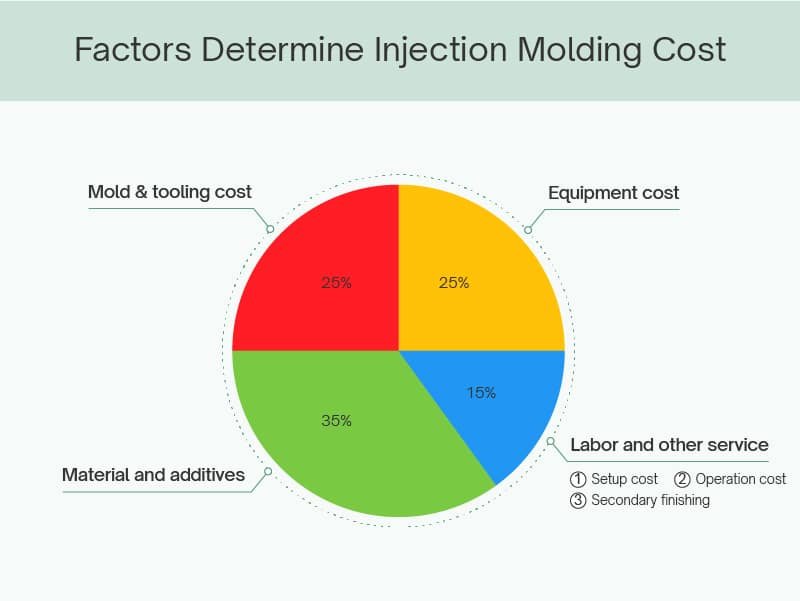

Rubber Injection Molding Cost

The primary factors that influence rubber injection molding cost include:

/Part1

Mold Design & Tooling

/Part2

Material

/Part3

Production Volume

/Part4

Part Complexity

/Part5

Secondary Services

The cost of rubber injection molding can vary widely depending on several key factors. Understanding these factors will help you get a clearer idea of the overall cost and make more informed decisions.

Related Resources of Rubber Injection Molding

Injection molding enabling the mass production of complex plastic parts with high precision and efficiency.

If you’re looking to cut down on injection molding mold costs, you’re in the right

The injection molding cost varies depending on a variety of factors, such as material choice,