Rubber Compression Molding Service

We Offer Rubber Compression Molding Service Specific to Your Needs!

Rubber compression molding is a method to shape rubber by placing a measured preform into a heated mold, then closing it with pressure and heat. The rubber cures under these conditions to match the mold cavity. This is a dependable way to make parts like seals, gaskets, and other flexible components with solid material performance.

At Erye Molding, we can provide professional rubber compression molding services that guide your part from concept to production with technical precision and practical insight.- In-house Mold & Tooling design and production to lower your upfront investment.

- Flexible part size range whether small or thick, simple or large.

- A wide range of rubber types including silicone, EPDM, neoprene, etc.

- Strong repeatability that ensure your parts stay consistent quality from batch to batch.

Rubber Compression Molding Process

STEP1

Mold & Preform Preparation

STEP2

Loading & Mold Closure

STEP3

Heat, Pressure & Cure

STEP4

Demolding, Trimming & Inspection

Available Rubber Compression Molding Materials

We offer a wide range of rubber materials for compression molding, composite materials are also available upon request.

- MVQ/Silicone

- EPDM (Ethylene Propylene Diene Monomer)

- NR (Natural Rubber)

- NBR (Nitrile Butadiene Rubber)

- CR/Neoprene (Chloroprene Rubber)

- SBR (Styrene-Butadiene Rubber)

- IIR/Butyl (Isobutylene isoprene rubber)

- FKM (Fluoroelastomer)

- FFKM (Perfluoroelastomer)

Rubber Compression Molding Components

These are examples of rubber products we typically make by compression molding.

- O-rings & Seals: Used to prevent fluid or gas leaks in pumps, valves, and hydraulic systems.

- Gaskets: Used between mating surfaces (e.g. engine covers, pipe flanges) to seal against pressure, oil, or moisture.

- Bushings / Vibration Mounts: Used in machinery or vehicles to absorb vibration, reduce noise, and protect components.

- Diaphragms: Thin flexible membranes used in valves, pressure sensors, or fluid control devices to separate chambers or control flow.

- Protective Boots / Covers: Used to shield moving joints, cables or connectors from dust, water, or environmental damage.

- Over-Molded Components: Used where a rubber sealing or flexible interface is bonded to a rigid substrate (metal/plastic) for durability or sealing in automotive, industrial, or electronics.

Features of Rubber Compression Molding

-

Advantages

- Lower tooling cost and simpler mold designs.

- Good for large, thick parts that need long cure times.

- Versatility with many rubber types, including high viscosity compounds.

- Efficient for low to medium volume production runs.

- Ability to include inserts or bond rubber to metal substrates.

- Minimal scrap when mold is well-designed; runners/gates often unnecessary.

- Lower machine complexity and simpler maintenance.

-

Disadvantages

- Longer cycle times, especially with thick or large parts.

- Flash formation at parting lines, requiring trimming.

- Mold wear and maintenance demands under high pressure/temperature cycles.

- Less suitable for very high production volumes compared to injection molding.

- Limited design flexibility for parts with undercuts, very thin walls, or sharp internal features.

Compression Molding Guide

Rubber Compression Molding FAQs

Related Resources of Rubber Compression Molding

Injection molding clamping force is an important factor to ensure the quality and precision of

What is the Meaning of Warpage Plastic warpage deformation, often seen as twisting or distortion,

Gas mark in injection moulding is a defect that appears on the gate area or

Ejector pin marks are a common defect on molded parts, appearing either as indentations or

Defined by polymers’ behavior under applied heat, there are 3 types of polymers-thermoplastics, thermosetting and

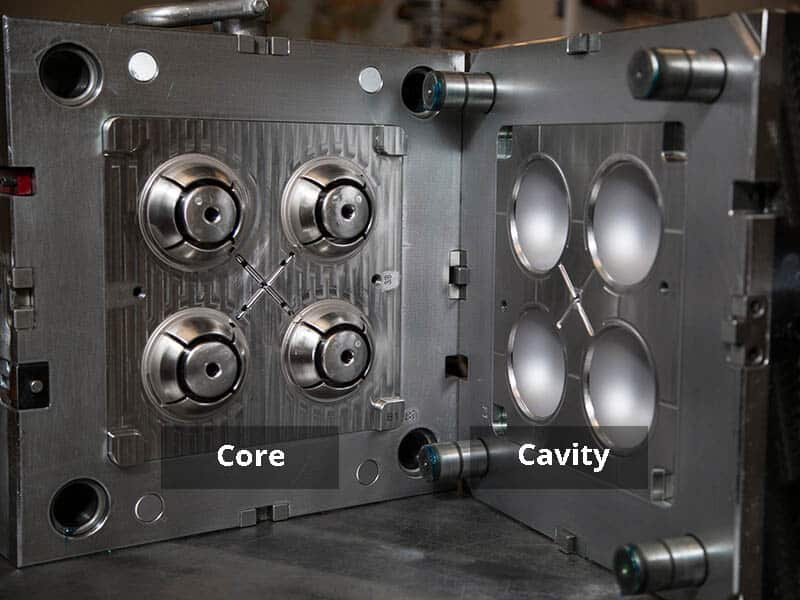

The core and cavity in injection molding are essential elements that define the shape, structure,