Polycarbonate Machining Services

We Provide CNC Polycarbonate Machining Service Specific to Your Need!

- Tight tolerance control, up to ±0.05 mm

- Stress control to ensure dimensional stability

- Fast turnaround for both small runs and large batches

- Support for custom finishing, assembly, and secondary operations

What is Machined Polycarbonate

Machined polycarbonate refers to parts made from solid PC sheets or rods through CNC milling or turning. Compared to other plastics, polycarbonate handles machining quite well—it doesn’t chip easily, holds tight tolerances, and can be cut into clear, impact-resistant parts. However, it does require careful speed and cooling control to avoid stress marks or clouding on the surface.

Machined Polycarbonate Grades We Work With

We work with a range of polycarbonate grades to meet different project needs—from clear visual prototypes to high-heat, high-impact industrial parts. Each grade has its own strengths, and we’re familiar with how they behave under CNC machining.

Here are some of the common grades Polycarbonate we machined. If you need other grades of ABS, please send us an email to sales@eycpu.com.

- General Purpose Polycarbonate

- Flame-Retardant Polycarbonate (UL94 V-0 Rated)

- Glass-Filled Polycarbonate

- Medical-Grade Polycarbonate

- Optical-Grade Polycarbonate

Types of CNC Polycarbonate We Offer

Machined Polycarbonate Properties

Here are the typical material properties of machined polycarbonate. Actual performance may vary depending on grade, additives, or fillers.| Item | Value |

|---|---|

| Tensile Strength | ~60 MPa |

| Flexural Strength | ~2,300 MPa |

| Impact Strength (Izod) | ~850 J/m |

| Heat Deflection Temperature | ~130°C at 1.8 MPa |

| Glass Transition Temp | ~150°C |

| Density | ~1.2 g/cm³ |

| Water Absorption (24h) | ~0.15% |

-

Key Benefits of CNC Polycarbonate

- Strong impact resistance

- Good clarity for transparent parts

- Holds tight tolerances

- Handles high temperatures

- Good electrical insulation

- Easy to bond or fasten

-

Shortcomings of CNC Polycarbonate

- Scratches easily

- Can crack under stress

- Sensitive to some chemicals

- Needs careful machining

- Higher material cost

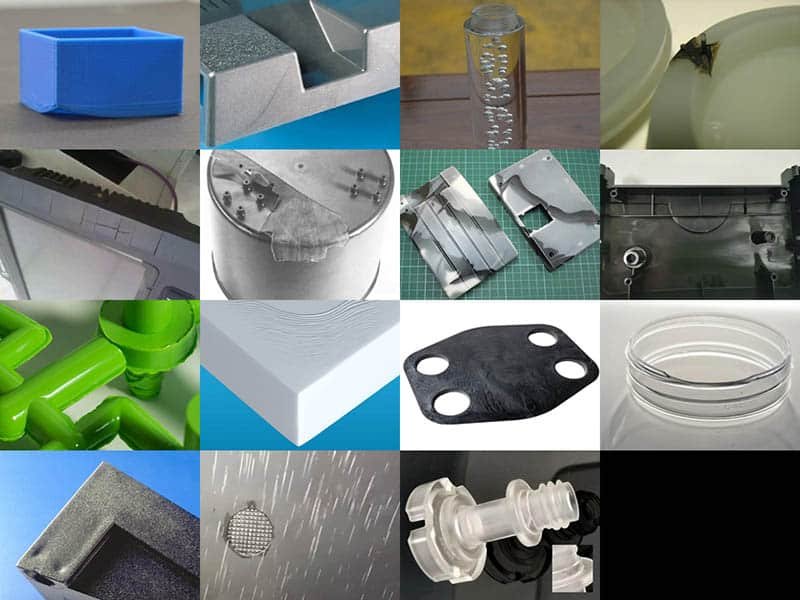

Popular CNC Polycarbonate Part

Here are some popular Polycarbonate machining parts we have made:

- Protective covers

- Light diffusers

- Transparent enclosures

- Electrical housings

- Control panels

- Display lenses

Have a Question?

Additonal Options for Polycarbontate Parts

Related Polycarbonate Machining Blogs

Low-volume injection molding is a manufacturing process that produces a smaller quantity of parts, typically

Ejector pin marks are a common defect on molded parts, appearing either as indentations or

Injection molding enabling the mass production of complex plastic parts with high precision and efficiency.

Surface finish in injection molding is a critical design consideration that significantly impacts both the