Plastic Compression Molding Service

We Offer Plastic Compression Molding Service Specific to Your Needs!

Plastic compression molding is a process where preheated plastic material is placed into a heated mold, pressed under high pressure, and formed into precise, durable components. It’s ideal for producing large, thick, or high-strength plastic parts with excellent surface quality.

We work closely with our customers at every stage—from material selection to final inspection—to make sure each part performs exactly as expected. Our experienced team handles the technical details so you can focus on your product’s success.- In-house mold design and manufacturing

- Capable of molding large and thick-wall parts

- Consistent quality for both small and large runs

- Excellent surface finish and dimensional accuracy

- Fast lead times and flexible order quantities

- Competitive pricing and efficient production cycles

Plastic Compression Molding Process

STEP1

Material Preparation

STEP2

Mold Loading

STEP3

Compression & Cure

STEP4

Demolding & Finishing

Available Plastic Compression Molding Materials

Not all plastics are suitable for this method. We currently specialize in PTFE and UHMWPE, which perform exceptionally well under compression. Other composite materials can also be evaluated and produced upon request.

- PTFE

- UHMWPE

Plastic Compression Molding Components

Plastic compression molding is ideal for producing durable, wear-resistant, and precisely formed parts from PTFE and UHMWPE. These materials are commonly used where low friction, chemical resistance, and dimensional stability are required. Some of the products we produced include,

- Sealing rings and gaskets

- Valve seats and diaphragms

- Bearing bushings and sleeves

- Wear plates and guide rails

- Insulating washers and spacers

- Pump and compressor components

- Custom machined blocks and discs

Features of Plastic Compression Molding

-

Advantages

- It can produce large, thick, or complex parts with excellent dimensional stability.

- The process generates minimal material waste, making it cost-efficient for certain applications.

- It allows precise control of pressure and temperature for consistent part quality.

- Molded parts have good surface finish and uniform density.

- It is suitable for high-performance materials such as PTFE and UHMWPE.

-

Disadvantages

- The production cycle is slower compared to injection or extrusion molding.

- It requires preheating of materials and longer curing times.

- The process is less suitable for high-volume, small-sized parts.

- Mold design and setup can be more time-consuming.

- Limite material range as not all plastics are compatible with compression molding.

Compression Molding Guide

Plastic Compression Molding FAQs

Yes, compression molding can integrate inserts, but it requires careful temperature and pressure control to ensure good bonding and avoid material distortion.

Related Resources of Plastic Compression Molding

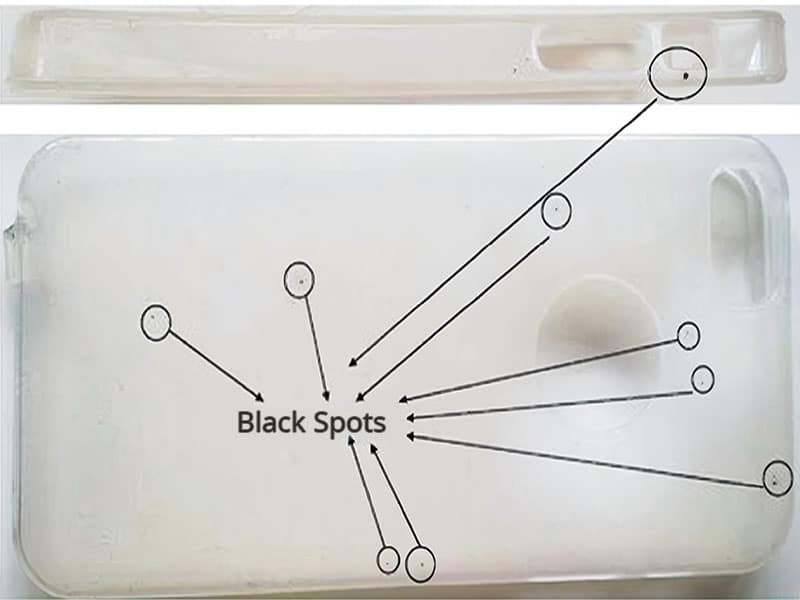

Black spots on plastic, and black specks are common visual defects in injection molding, appearing

Jetting in injection molding creates worm-like defects when molten plastic shoots through the gate unchecked.

Reaction Injection Molding (RIM), is a specialized manufacturing process tailored for producing plastic parts, particularly

Surface finish in injection molding is a critical design consideration that significantly impacts both the

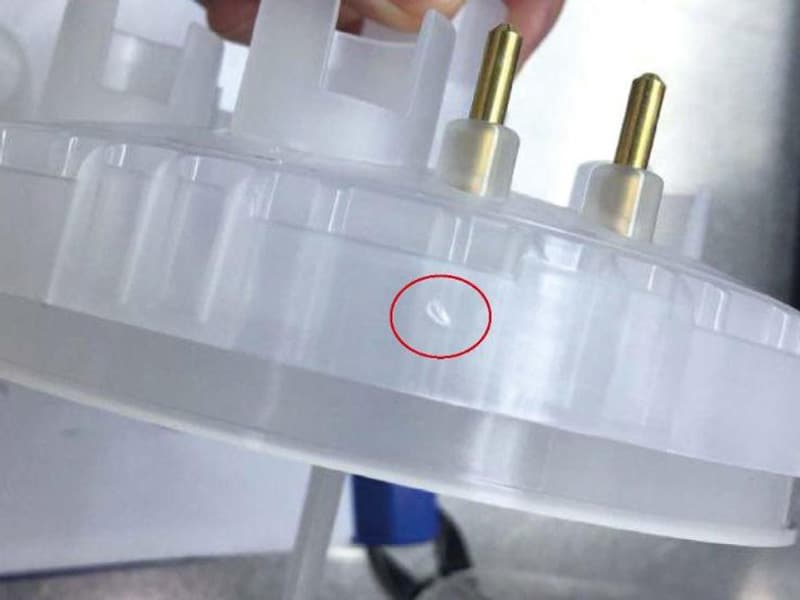

Air bubbles in injection molding are defects that can occur during the manufacturing of products,

Design for manufacturing is the key to transforming a great concept into a cost-effective, high-quality