China Injection Molding Overmolding Service

We specialized in injection molding Overmolding Service that combine multiple materials into a single component.

Overmolding is a manufacturing process where multiple types of materials are molded together to form a single cohesive component. It is a two-step procedure, start with a pre-shaped substrate material, which can be made from plastic, metal, or other material, then covered with an additional layer of plastic or rubber.

Benefits of overmolding include:- Improved functionality with better shock absorption, and insulation

- Ehanced grip and tactile feel by adding layer to a rigid part

- Multi-color or multi-material design that improve aesthetics

- Protective layer increased part durability

- Reduce assembly steps, and cost saving

Overmolding Services Specifiactions

| Service | Details |

|---|---|

| Process Materials | Most plastics and rubber, including custom sourcing, see material list below |

| Standard Finishes | SPI and VDI |

| Mold Service | DFM report and mold flow analysis |

| Mold Ownership | Customer owned with regular mold maintenance |

| Mold Cavities | Single or multi-cavities |

| Mold Life | Unlimited (If the mold worn out, Erye will cover the cost for the new set of mold) |

Overmolding Service Process

Plastic over plastic

Plastic over metal

Rubber over metal

Rubber over plastic

Materials for Overmolding Service

Substrate Materials for Overmolding

Plastics

- Polypropylene (PP)

- Polyethylene (PE)

- Acrylonitrile Butadiene Styrene (ABS)

- Polycarbonate (PC)

- Nylon (PA)

- Polyurethane (PU)

Metals

- Aluminum

- Steel

- Brass

Composites

- Glass-reinforced plastics

- Carbon-reinforced plastics

Bonding Materials for Overmolding

Rubbers

- Silicone

- EPDM

- NR (Natural rubber)

- NBR (Nitrile butadiene rubber)

- SBR (Styrene-butadiene)

- CR (Chloroprene rubber, neoprene)

- FKM (Fluoro-Elastomer)

- FKKM (Perfluorelastomer)

Thermoplastics

- Thermoplastic Elastomers (TPE)

- Thermoplastic Polyurethane (TPU)

- Polyvinyl Chloride (PVC)

- Polyurethane (PU)

Overmolding Guide

Overmolding Surface Finishing Standard

| Finishing | Description | Price Range | SPI Grades |

|---|---|---|---|

|

Provides a highly reflective surface, ideal for aesthetic applications such as consumer products. | $$$ | SPI A1, A2, A3 |

|

Offers a moderate sheen, balancing gloss and matte, suitable for parts needing some visual appeal without being overly shiny. | $ | SPI B1, B2, B3 |

|

Features a non-reflextive surface that reduce glare, often used for functional parts where aesthetics are less critical. | $$ | SPI C1, C2, C3 |

|

Enhances grip and durability, commonly applied to functional components to improve handling and reduce wear. | $$$ | SPI D1, D2, D3 |

SPI A: Glossy Finish

Provides a highly reflective surface, ideal for aesthetic applications such as consumer products.

- Price Range: $$$

- SPI Finish Grades: SPI A1, A2, A3

SPI B: Semi-Gloss Finish

Offers a moderate sheen, balancing gloss and matte, suitable for parts needing some visual appeal without being overly shiny.

- Price Range: $

- SPI Finish Grades: SPI B1, B2, B3

SPI C: Matte Finish

Features a non-reflective surface that reduces glare, often used for functional parts where aesthetics are less critical.

- Price Range: $$

- SPI Finish Grades: SPI C1, C2, C3

SPI D: Textured Finish

Enhances grip and durability, commonly applied to functional components to improve handling and reduce wear.

- Price: $$$

- SPI Finish Grades: SPI D1, D2, D3

Advantages of Overmolding with Us

Enhanced Functionality

Reduced Assembly Time and Costs

Improved Durability

Overmolding Applications

Overmolding FAQs

Related Resources of Overmolding

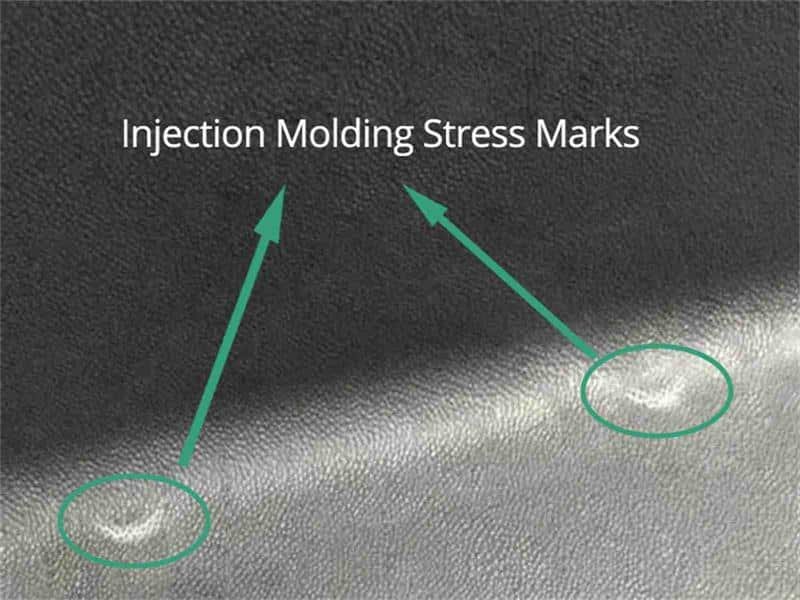

Shiny white marks on your molded parts signify internal stress. You must acknowledge that ignoring

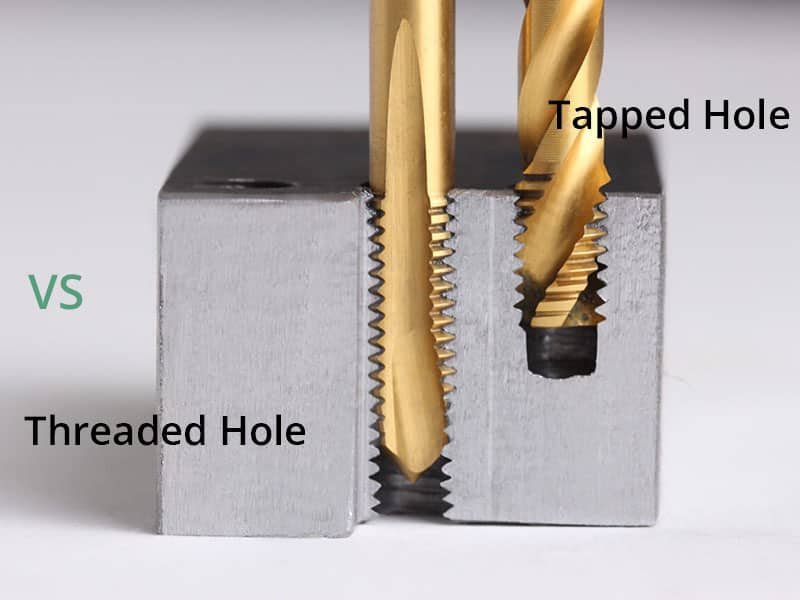

Tapped holes and threaded holes play crucial roles in joining plastic parts or plastics to

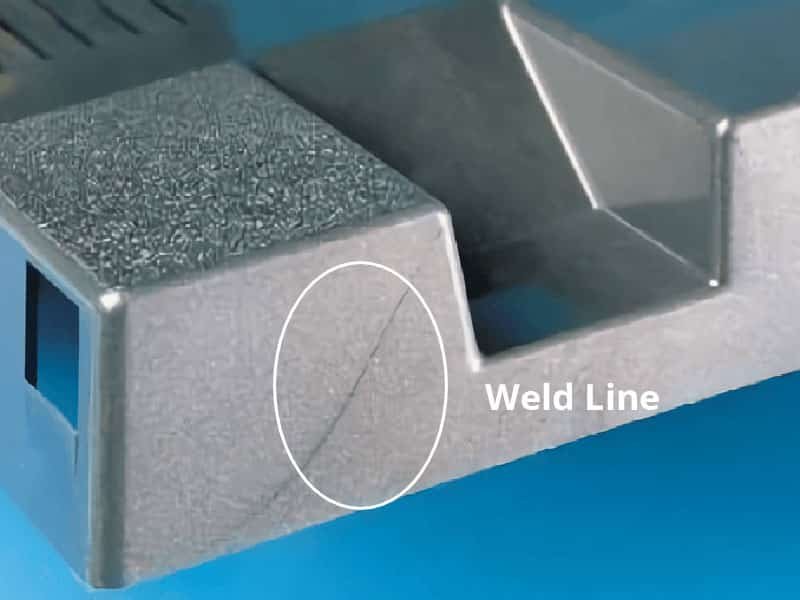

Jetting in injection molding creates worm-like defects when molten plastic shoots through the gate unchecked.

Living hinges design is among the most effective features in plastic design. They allow two

Off topic, but a fun fact: When you look at a plastic bottle cap under

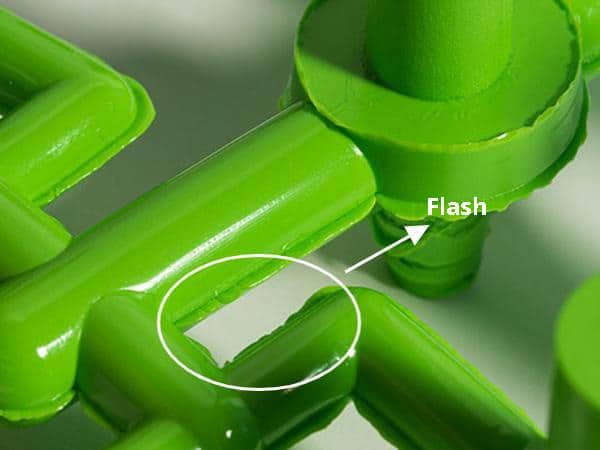

Flash in injection molding is one of the most common plastic molding defects. It significantly