Nylon Injection Molding

Erye Offer Nylon Injection Molding Service Specific to Your Needs!

- Low-volume and high-volume production

- Small to large part size

- Free & fast DFM report

- No mininum order quantities

- T1 samples as fast as 10 days

What is Nylon Plastic Material?

Nylon belongs to the polyamide family, is a synthetic thermoplastic polymer. It is widely used in various fields due to its high strength and durability. Injection-molded nylon offers excellent wear resistance, chemical resistance, and heat resistance, and can be molded into a variety of styles and structures.

The numbers in the nylon names (like 6, 6/6, 11, etc.) refer to the number of carbon atoms in the monomers that make up the polymer chain. The common types of Nylon material include:

- Nylon 6 (PA6): The high moisture absorption (around 2.5-3% at saturation) can impact dimensional stability.

- Nylon 6/6 (PA66): Offers better tensile strength (around 80-90 MPa) compared to PA6.

- Nylon 11 (PA11): Demonstrates exceptionally low moisture absorption (around 0.1-0.4% at saturation).

- Nylon 12 (PA12): Provides excellent dimensional stability with minimal water uptake (around 0.1-0.3% at saturation).

- Nylon 4/6 (PA46): This delivers high heat deflection temperature (around 290°C), suitable for high-temperature applications.

- Glass-filled Nylon: Increased tensile strength and boosted stiffness up to 70% greater than unfilled nylon.

Nylon Injection Molding Services

| Service | Details |

|---|---|

| Maximum Part Size | 2500mm x 2000mm (98 in. x 78 in.) |

| Recommended Wall Thickness | 1.2mm - 3.5mm (0.0472 in. x 0.1378 in.) |

| Color Options | Any color according to RAL or Pantone Code |

| Standard Finishes | SPI and VDI |

| Mold Ownership | Customer owned with mold maintenance |

| Mold Life | Unlimited (If the Nylon injection mold worn out, Erye will cover the cost of new mold) |

Injection Molded Nylon Part Design Guide

| Item | Description |

|---|---|

| Wall Thickness | Maintain uniform wall thickness between 1.5mm to 3.0mm to reduce warping and stress during cooling. |

| Draft Angles | Design draft angles of at least 1-2 degrees to facilitate part ejection and prevent damage during mold release, as nylon shrinks onto the mold. |

| Ribs and Bosses | Keep rib thickness at no more than half the wall thickness to avoid warping and stress concentration, especially for parts requiring increased rigidity. |

| Tolerance | Account for 1.5% to 2.5% shrinkage during molding, to ensure the final part dimensions meet the required tolerances. |

| Snap-Fit Design | Utilize snap-fit features with appropriate undercut and deflection allowances, accounting for nylon's flexibility and potential creep. |

| Hole Design | Design holes with adequate spacing and diameter to prevent cracking and ensure proper functionality, considering nylon's shrinkage and potential for stress concentration. |

Tips: For glass-filled nylon injection molding, consider a thicker wall thickness to ensure the final product has optical and mechanical strength and avoids weak points.

Advantages of Nylon Molding

High Strength and Durability

Chemical Resistance

Temperature Resistance

Reduced Friction

Electrical Insulation

Disadvantages of Nylon Molding

Moisture Absorption (Hygroscopicity)

High Shrinkage

Brittleness at Low Temperatures

Application of Injection Molded Nylon

Automotive Industry

- Timing gears

- Radiator end tank caps

- Interior door handle mechanism

- Airbag component housings

Industrial

- Conveyor belt rollers

- Linear motion bushings

- Pump housings

- Valve components

- Pipe fittings

Medical Industry

- Infusion pump housings

- Dialysis machine connectors

- Medical instrument handles

- Diagnostic device housings

Aerospace Industry

- Seat track rollers

- Wire bundle clamps

- Interior panel fasteners

- Instrument panel components

- Access panel latches

Additonal Options for Nylon Parts

From Idea to Production: Vacuum Cleaner Mold Case Study

Related Nylon Molding Resources

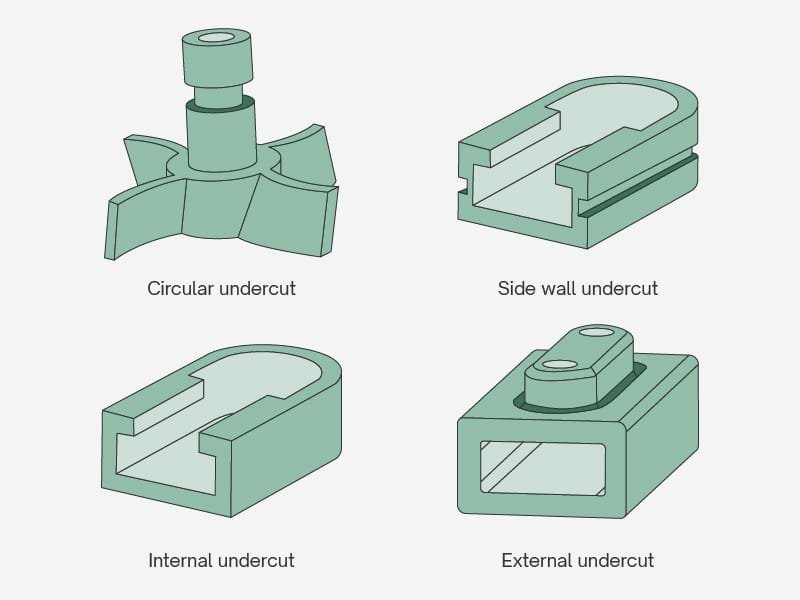

Injection molding undercuts is any protrusion or recessed feature on a plastic part that prevents

The success of the injection molding process hinges on several injection molding parameter that influence

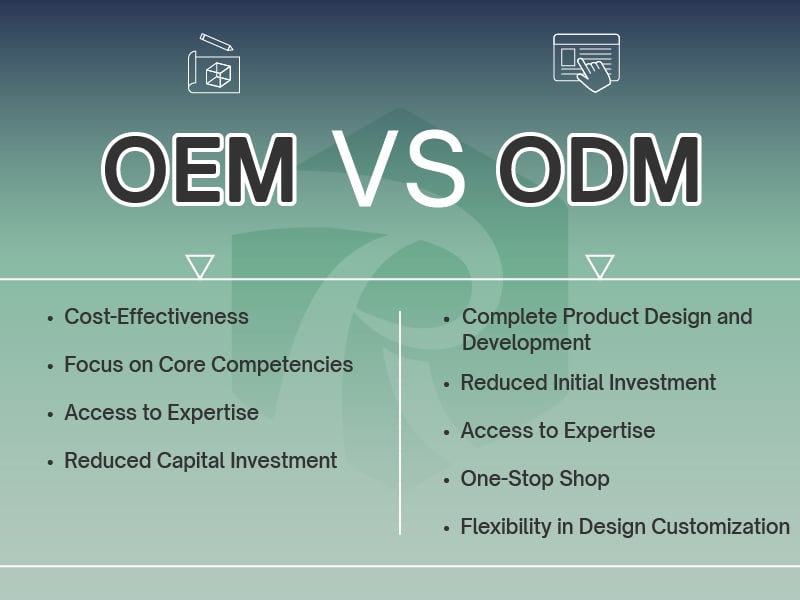

What Is Orginal Equipment Manufacturer? – OEM Meaning Original Equipment Manufacturer (OEM) means a company