ABS Injection Molding Service

Erye Offer ABS Plastic Injection Molding Service Specific to Your Needs!

ABS (Acrylonitrile Butadiene Styrene) is a common thermoplastic used in the injection molding process. While ABS has excellent toughness, strength, and high impact resistance, it is relatively inexpensive. It is often used in electronics components and consumer goods, but ABS needs additives to enhance UV resistance for outdoor applications.

Erye specializes in custom ABS injection molding service. We offer custom manufacturing service from concept to final production.- Injection mold costs start from $750

- Low-volume and high-volume production

- Small to large part size

- Free & fast DFM report

- No mininum order quantities

- T1 samples as fast as 10 days

ABS Injection Molding Services

| Service | Details |

|---|---|

| Maximum Part Size | 2500mm x 2000mm (98 in. x 78 in.) |

| Recommended Wall Thickness | 1.2mm - 3.5mm (0.0472 in. x 0.1378 in.) |

| Color Options | Any color according to RAL or Pantone Code |

| Standard Finishes | SPI and VDI |

| Mold Ownership | Customer owned with mold maintenance |

| Mold Life | Unlimited (If the ABS mold worn out, Erye will cover the cost of new mold) |

ABS Plastic Molding Design Guidelines

| Item | Description |

|---|---|

| Wall Thickness | Recommended Thickness: 2-4 mm (0.08-0.16 inches). Use ribs to strengthen thin walls, keeping their thickness 50-60% of the main wall. |

| Draft Angles | To ensure smooth ejection from the mold, parts should have a draft angle 1-2° for most features. For textured surfaces, increase to 3-5°. |

| Radii and Corner | Avoid sharp corners to reduce stress concentrations, use a minimum radius of 0.5-1 mm (0.02-0.04 inches) for corners. |

| Shrinkage | ABS typically shrinks 0.4-0.7% during cooling, account for shrinkage in part dimensions and mold design. |

| Undercut | Design parts to minimize undercuts, use side actions, lifters, or collapsible cores if undercuts are unavoidable. |

| Surface Finish | ABS can be molded with various surface finishes, from glossy to matte, it also can be painted, chromed, or textured for enhanced aesthetics. |

Advantages of ABS Molding

High impact resistance under normal use

Ease of processing

Dimensional stability

Good chemical resistance

Relatively low cost

Disadvantages of ABS Molding

Poor UV and weather resistant

Limited high-heat load performance

Flammability concerns

Moisture absorption may lead to defects

Custom ABS Plastic Molding Application

Automotive Industry

- Dashboards

- Interior trim

- Knobs and buttons on the dashboard

- Door handles

- Mirror housings

Consumer Electronics

- Smartphone cases

- Computer housings

- Keyboards

- Mouse enclosures

- Tablet cases

- Remote control housings

Toys Industry

- Action figures

- Board game pieces

- Toy vehicles

- Puzzle pieces

- Toy guns and accessories

Sporting Goods

- Bicycle parts

- Helmets

- Ski poles

- Fitness equipment enclosures

- Golf club heads

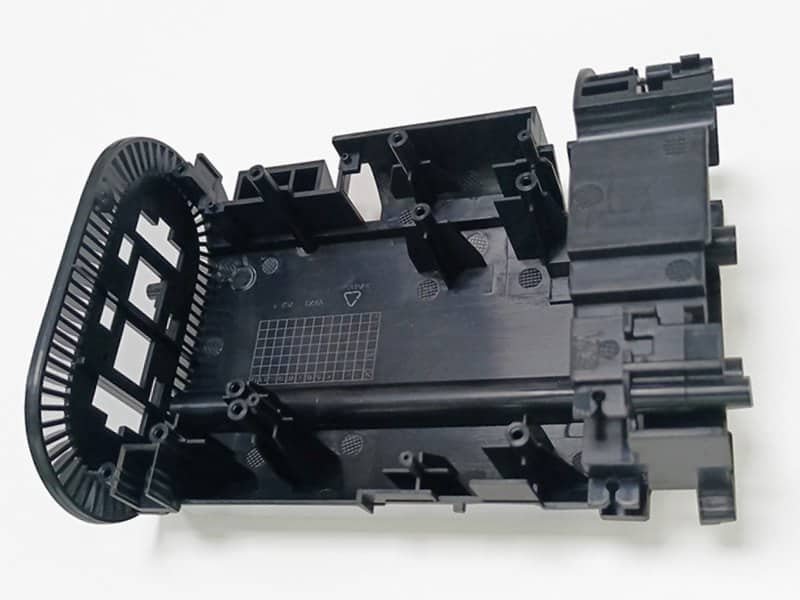

Case Study of Automotive Car Dashboard Molding

Additonal Options for ABS Parts

ABS Plastic Manufacturing Guide

ABS Injection Molding Process

- Material Pre-treatment: ABS resins must be dried before processing, as they tend to absorb moisture. General-grade ABS should be baked at 80-85°C for 2-4 hours or treated in a dry hopper at 80°C for 1-2 hours to restrict the moisture content to less than 0.1%.

- ABS Melting and Injected into the Mold: ABS plastic pellets are melted into a moldable state, and then the molten ABS is injected into the mold cavity. The ABS melting temperature typically ranges from 200 to 260°C; attention needs to be paid to avoid excessive heat.

- Injection Molding Process: It consists of three critical stages:

- Fill stage – ABS material is injected into the mold.

- Pack stage – Pressure is adjusted to inject more ABS material into the mold to account for shrinkage and backflow.

- Hold stage – The material is held at a fixed pressure until the cooling process begins.

- Cooling: Once the mold is filled, the molten plastic solidifies and cools to take the shape of the mold. Inadequate cooling can lead to surface imperfections, so properly designed wall thickness and an improved cooling system are vital.

- Ejection and Reset: After the part has fully cooled, the mold sides open to eject the part. The mold parts are then reset to begin the process again.

Explore The Step-to-Step to Injection Molding Process.

Several factors must be considered during the ABS injection molding process, including wall thickness, shrinkage rate, stress concentration, melt temperature, injection pressure, injection molding speed, and cooling rate. Maintaining uniform wall thickness is important to avoid stress on the plastic part. The injection speed should also be adjusted to enhance surface quality, as an overly low speed can result in insufficient plastic density and poor gloss.

Pre-treatment of the material, selection of appropriate process parameters, and careful mold design contribute to a reliable and repeatable injection molding process for ABS parts. For complex ABS injection molding tooling, a series of processing technologies such as CNC milling, EDM, deep hole drilling, lathe, grinding machine, and wire-electrode cutting may be used.

Consideration During ABS Injection Molding Process

- Material Drying: Properly dry ABS pellets to remove moisture, as trapped water can lead to defects such as bubbles and surface imperfections.

- Molding Machine Setup: Calibrate machine settings, including temperature, pressure, and injection speed, based on the specific characteristics of ABS.

- Injection Pressure and Speed: Adjust injection pressure (typically 50-150 MPa) and speed to ensure thorough filling of the mold without defects like short shots.

- Temperature Control: Maintain precise control over barrel and mold temperatures. Barrel temperatures generally range from 200 to 230°C, while mold temperatures are typically set between 50 and 80°C.

- Cooling Rate: Optimize cooling rates to prevent warping or shrinkage and ensure uniform solidification of the part.

- Wall Thickness and Design: Design molds with appropriate wall thickness, draft angles, and venting to avoid defects like warping or flash.

- Shrinkage Management: Understand the material’s shrinkage characteristics to design mold cavities that ensure accurate final dimensions.

- Cycle Time: Balance efficient cycle times with adequate cooling periods to maintain part quality while maximizing productivity.

- Quality Control: Implement quality checks throughout the process to quickly identify and rectify issues, ensuring consistency in production.

- Post-Processing Considerations: Plan for any necessary post-processing steps, such as trimming or surface finishing, to achieve the desired product quality.

Have a Question?

Related ABS Molding Resources

Low pressure overmolding is a manufacturing technique used to mold multiple materials into a single

Low-volume injection molding is a manufacturing process that produces a smaller quantity of parts, typically

Living hinges design is among the most effective features in plastic design. They allow two