Air bubbles in injection molding are defects that can occur during the manufacturing of products, particularly in plastics. They form when the center of the product’s wall thickness cools more slowly than the surface, leading to uneven contraction and cavities. Additionally, when raw materials decompose under heat, the water and air produced can create more air bubbles inside the product.

These air bubbles typically appear as numerous small voids within the finished product and may be accompanied by silver streaks on the surface. For products requiring water-proof performance, even a tiny air bubble can render the entire product defective, especially in severe cases. This is critical for precision and high-quality parts, which must be free from such defects to meet industry standards.

To fix air bubble in injection molding, start by observing the product, issues related to product design, the type of plastic materials used, and the mold can typically be spotted. This initial inspection helps in making a preliminary assessment, which is usually straightforward. After forming an initial evaluation, the next step involves adjusting the parameters of the injection molding process. This adjustment helps in gaining a clearer insight into the problem, allowing for the identification of the exact cause behind the air bubble defect.

Erye is a China injection molding factory. Based on our experience, the following are common causes of and solutions for air bubbles in injection molding.

Uneven Wall Thickness

When the product has uneven thickness with locally thick areas, this can trap air, leading to air bubbles in the injection. During the injection molding process, thick sections may freeze quickly, preventing proper filling and causing bubbles.

Designing products with uniform wall thickness can ensure even material flow and reduce the risk of air being trapped.

Improper Material Selection or Handling

Unsuitable materials can trap air and lead to bubbles. Common issues include:

- Mixing other plastics into raw materials or adding too much powder to pellets traps air during melting. This is often due to improper material handling or contamination, leading to air entrapment in the melt stream.

- Recycled plastics often have loose pellet structures with micropores that retain significant amounts of air. Using recycled resin can lead to gas release during processing, forming air bubbles.

- Raw materials containing volatile solvents or liquid additives, such as white oil (a lubricant for dyeing), silicone oil (a lubricant), dibutyl phthalate (a plasticizer), stabilizers, and antistatic agents, can cause issues. If these additives are used excessively or mixed unevenly, they can enter the mold cavity in aggregates, trapping air and forming bubbles.

- Plastics not subjected to drying treatment or absorbing moisture from the atmosphere can lead to bubble formation. Moisture vaporizes during processing, creating air bubbles.

- Certain grades of plastics cannot handle high temperatures or long heating times, leading to degradation and bubble formation.

How to Fix the Problem

To reduce air bubbles, consider these solutions:

- Using uncontaminated, pure raw materials reduces the risk of air-trapping issues caused by mixing with other plastics or powders.

- Limit or avoid using recycled materials to minimize air retention.

- Reduce the use of additives, especially volatile ones like white oil, silicone oil, and dibutyl phthalate.

- Dry the plastic for the recommended time according to material standards to remove moisture.

- Change the material grade to one with better heat resistance or add additives to improve performance under high temperatures.

Inadequate Mold Design

Mold design problems can trap air or create conditions that lead to bubbles during manufacturing. Here are the main causes:

- Mold Design Flaws: Poor gate location, small gates, narrow runners, and unreasonable cooling systems, causing excessive mold temperature differences, leading to discontinuous melt flow, blocking air channels

- Venting Problems: If the mold doesn’t have enough vents or they get blocked, especially at the parting line where the mold halves meet, air can get trapped, causing bubbles.

- Surface Roughness: A rough mold surface increases friction, leading to local overheating, which can decompose the plastic and release gases, forming bubbles.

How to Fix the Problem

To fix the air bubbles caused by the mold design, the following steps can be taken:

- Adjusting the gate location and runner size ensures better material flow and reduces temperature differences, ensuring gates are ≥50% of wall depth

- Add or enlarge venting slots, especially at the parting line, to let air escape during the process.

- Reduce surface roughness of the mold to reduce friction and overheating, based on application needs and product appearance requirements.

Injection Molding Process Problem

Improper settings or operations during the injection molding process can lead to air bubbles, with common causes including:

- The material temperature is too high, causing the plastic to decompose and release gases.

- Low injection pressure and short holding time prevent the melt from fully adhering to the mold cavity surface, trapping air.

- Fast injection speed can cause shear heating, decomposing the plastic and generating gases, while slow speed fails to fill the cavity in time, leaving low-density areas where air gets trapped, forming bubbles.

- Insufficient material quantity, too much material cushion, material temperature too Low, or mold temperature too low can all affect the flow of the melt and molding pressure, causing air bubbles

- Multi-stage injection involves varying speeds and pressures (medium for runners, slow for gates, fast then low-pressure slow) to control flow and expel gases, but improper staging can trap air, causing bubbles.

- Low back pressure and high screw speed during pre-plasticizing can trap air between plastic granules, pushing it forward and forming bubbles in the mold.

How to Fix the Problem

Adjusting the following parameters can effectively solve these issues:

- Reducing material temperature prevents thermal decomposition, reducing gas generation and bubble formation.

- Higher pressure and longer hold time ensure better packing, forcing out trapped air and reducing bubbles.

- Adjust injection speed based on product structure, balancing fast and slow stages to avoid shear or incomplete filling.

- Increase the material quantity to ensure enough melt for filling.

- Use multi-stage injection with controlled speeds (medium for runners, slow for gates, fast then low-pressure slow) to expel gases.

- Higher back pressure and slower screw speed during pre-plasticizing reduce air entrapment, preventing bubbles.

Case Study–How to Avoid Air Bubble in Injection Molding

The following is a practical case study conducted by Erye engineering team on how to avoid air traps in injection molding.

Project Introduction

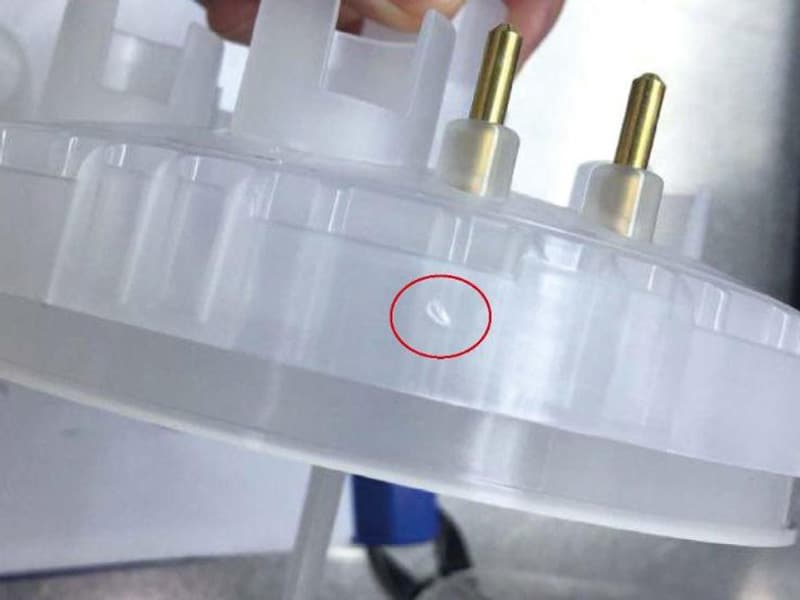

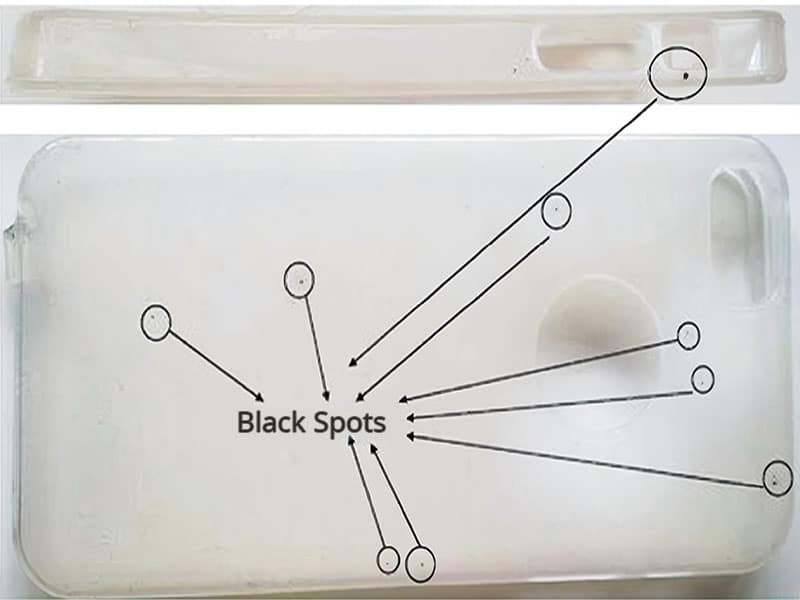

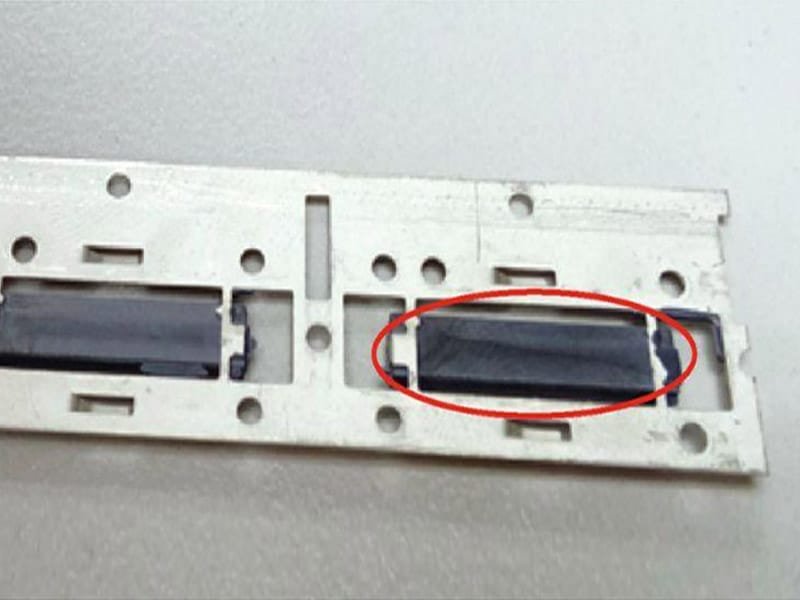

The picture shows an example of an air trap in injection molding. The product is made from LCP (liquid crystal polymer), with an average wall thickness of 0.3mm. Mold design incorporates an edge gate for feeding. The overall dimension of this part is relatively small, with 0.2mm in wall thickness at the thinnest section. To meet the client’s performance requirement, we use high-temperature-resistant engineering plastic. Following the injection molding process, the product is subjected to high-temperature baking.

Troubleshooting

After the injection molding process, during the backing stage, the external plastic layer separates from the internal components, and there are cracks and air bubbles at the weld line.

How to Fix an Air Trap in Injection Molding

Case Analysis

From examining the product’s drawings and samples, it appears that cracking and bubbles are seen at the thinnest sections. The products showed no such defects before the baking process, which indicates the heat treatment might trigger these issues.

After backing, cracks and bubbles appear at the weld lines, suggesting that the baking process exacerbates weaknesses in the material, particularly at these stress points.

It can be inferred that the thin wall thickness is likely inadequate to withstand the internal gas pressure generated during high-temperature backing, leading to cracking and air bubbles.

Test and Validation

When trying to fix defects in plastic injection molding, it is common to tweak how fast the material is injected, and the temperatures of the material and mold. Therefore, our engineers tried high and low speeds, and high and low temperatures for both. Our tested combinations like fast injection with hot material, or slow injection with a cool mold, and many others, but nothing worked well.

Solution

It looks like the product’s thin walls couldn’t handle the heat during baking, letting gas escape and causing defects. Changing the injection settings didn’t help enough, suggesting the design or material might need a rethink.

After talking with the development team, it is acceptable to increase the wall thickness by 0.02mm at the 0.2mm thinnest point, ensuring it still meets the drawing’s size requirements and doesn’t affect how final usage. When we tried molding agian, the problems were solved, leading to stable production and delivering good products.

Conclusion

By implementing the solutions discussed above, you can effectively address air bubble defects in injection molding. If you encounter further challenges or require assistance with other injection molding troubleshooting issues, please feel free to contact us. As a professional manufacturer, Erye Molding is committed to providing expert support and solutions tailored to your needs.