If you’re looking to cut down on injection molding mold costs, you’re in the right place. Whether you’re a designer or manufacturer, everyone wants to save money without sacrificing quality. This list of practical tips will show you exactly how to reduce your injection molding tooling costs—focusing on simple design tweaks, material choices, and even some smart molding techniques. These are real, actionable strategies that can make a difference in your next project.

To better understand the tips to reduce injection molding costs, you may want to read our blog How Much Does Injection Molding Cost, to learn what factors determine the cost and how much does it cost.

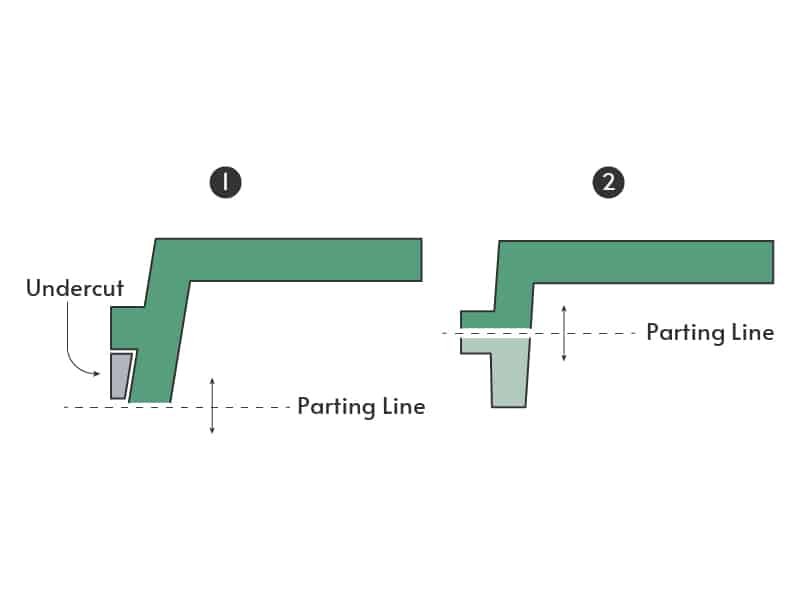

1. Eliminate Undercut

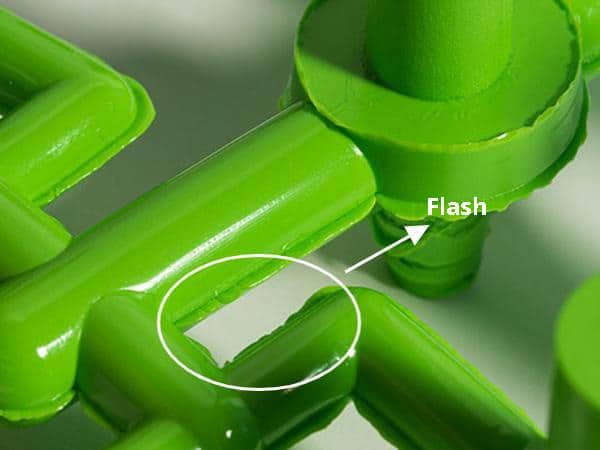

Undercuts complicate mold design and ejection, increasing both time and costs. It require additional mold mechanisms, such as slides or lifters, to release parts from the mold cavity. For example, a part with a clip feature and undercut would normally need sliding cores. However, by modifying the design—such as adding a simple slot underneath—the tooling process becomes much simpler and more affordable.

While some undercuts are essential for part functionality or aesthetics, unnecessary ones should be avoided. By eliminating unnecessary undercuts, you can simplify the mold, reduce complexity, and lower production expenses.

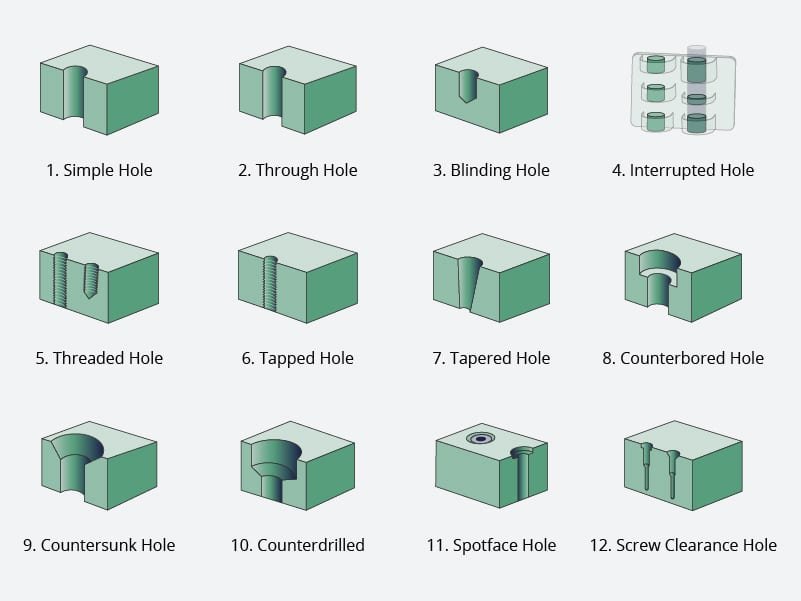

2. Remove Unnecessary Features

Evaluate your design to identify any elements that do not significantly enhance the product’s functionality or appearance. Unneeded functions such as extra surface textures, non-functional ribs, or embossed logos and patterns can often be removed without compromising the product’s performance. These unnecessary features add complexity to the mold, resulting in higher tooling costs.

In some cases, features like logos or textures are required for product branding or regulatory compliance. However, using sensible design practices can minimize additional costs. For example, choosing simple fonts like Arial or Verdana for logos and text, and keeping the depth of engravings under 0.015 inches, can help reduce costs without sacrificing necessary branding or regulatory elements.

3. Reduce Cosmetic Finishes and Appearances

Achieving a high cosmetic finish often involves additional processes like bead blasting, EDM, or extensive mold polishing, all of which increase tooling costs. Finishes that go beyond a standard PM-F0 (as-machined) finish typically require handwork, sometimes up to an SPI-A2 mirror finish using Grade #2 diamond buffs.

While shiny, glossy finishes may enhance a product’s aesthetic appeal, they also drive up tooling and labor costs significantly. If the finish isn’t critical to the product’s functionality or overall value, it’s best to skip it altogether to reduce expenses.

4. Take Part Size into Consideration

When designing parts, always account for their size and how well they will fit into the mold. The part size affects how much room is available for essential elements like sprues, runners, and ejector pins, all of which are necessary for proper mold operation. Larger parts require bigger molds, which, in turn, increase tooling and part costs. Furthermore, large parts or features that could lead to higher material costs and longer cycle times due to additional molding and cooling requirements

Often, using less material can result in stronger parts, as overuse of material doesn’t necessarily translate into greater structural integrity. Keep your design lean, focusing on the necessary material for strength and functionality.

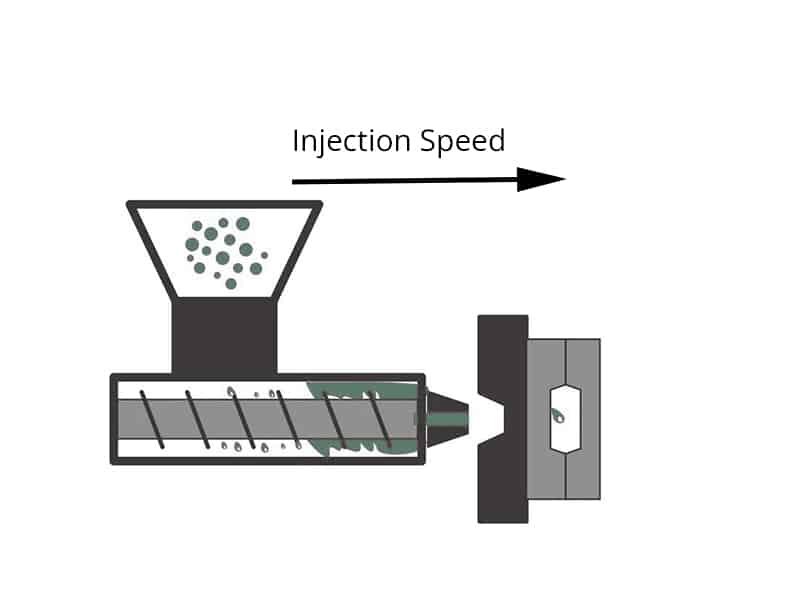

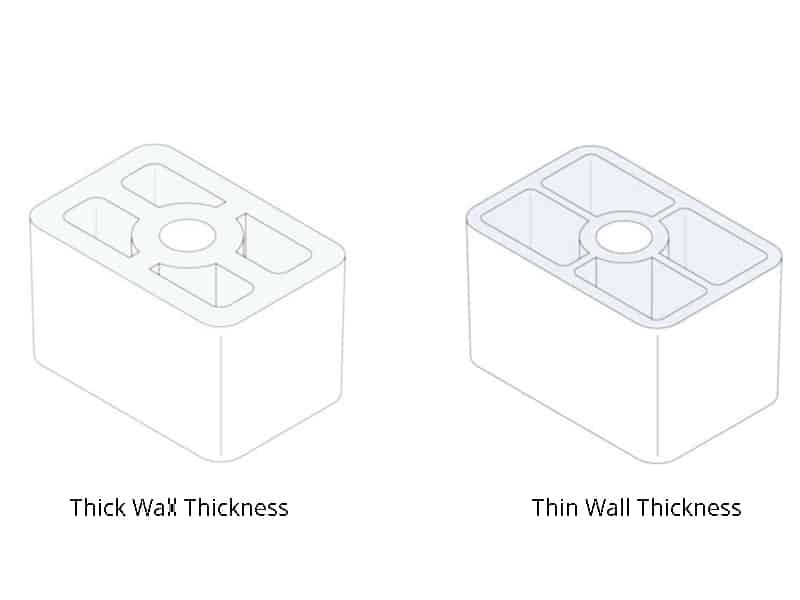

5. Minimize the Part Volume by Reducing Wall Thickness

Maintaining uniform wall thickness throughout the part ensures consistent cooling, minimizes warping, and reduces material usage. Thinner walls not only use less material but also speed up the injection molding cycle. For example, reducing the wall thickness from 3mm to 2mm can cut the cycle time by 50 to 75%. Thinner walls allow the mold to fill more quickly, and the part cools faster. Since nearly half of the injection molding cycle is dedicated to cooling, thinner parts lead to a more efficient process.

However, balance is key. Thinning the walls too much could compromise the part’s rigidity, affecting its performance. To maintain strength, consider adding ribs in strategic areas. This allows for a thinner, more cost-efficient design without sacrificing functionality.

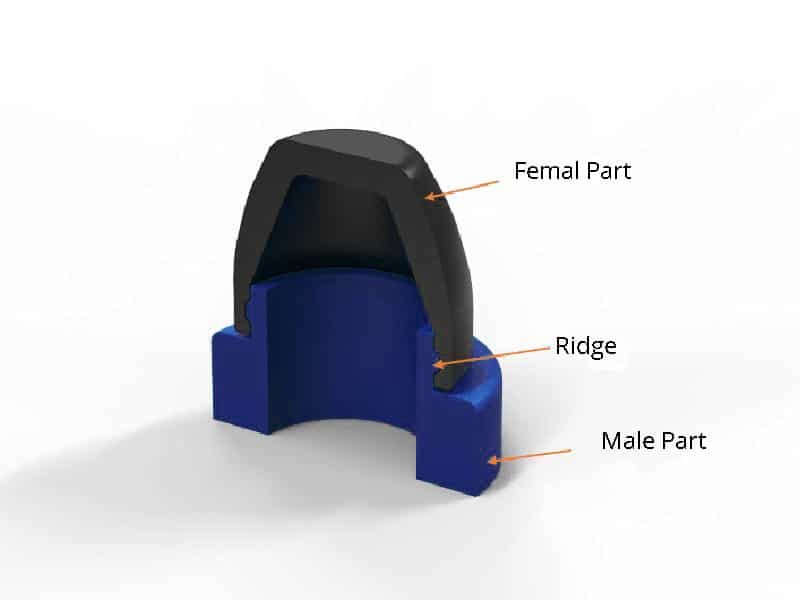

6. Design Self-Mating Parts

Self-mating parts, such as those used in snap cases or interlocking components, allowing them to attach to themselves. By designing parts that can be assembled without the need for additional components, you eliminate the need for complex mating parts. This design approach allows you to use a single mold, cutting down on mold costs and reducing the injection mold size by half.

7. Choose the Right Material

The type of plastic you choose can significantly impact both the cost and production time. For cost-effective solutions, polypropylene is a great option. It’s affordable, easy to work with, and doesn’t require much post-processing. However, for more durable or stronger parts, materials like nylon or polycarbonate might be better choices. While these are more expensive, they can withstand higher temperatures and offer long-term reliability.

Unless your part needs to meet specific requirements like extreme temperature resistance or food-grade standards, material selection is often flexible. By analyzing your product’s intended use and market, you can make an informed decision to keep costs in check without sacrificing functionality. Additionally, staying up-to-date with new material advancements can present cost-effective alternatives without compromising quality.

8. Pay Attention to DFM Analysis

A Design for Manufacturability (DFM) analysis is a critical tool to help reduce costs in the injection molding process. When you receive a quote, the DFM analysis identifies potential issues like non-machinable parts, insufficient draft angles, or problematic geometries in your design. These recommendations are essential to optimize the design before proceeding. Reviewing these suggestions thoroughly can prevent costly errors and ensure smoother production. If you have any questions about the analysis or design modifications, don’t hesitate to consult with an applications engineer for expert advice.

9. Use Family or Multi-Cavity Mold

One effective way to reduce tooling expenses is by utilizing family or multi-cavity molds. Multi-cavity molds are ideal for high-volume production, as they allow more parts to be created in each cycle, which ultimately lowers the per-unit cost over time. Although tooling costs might be higher initially, this approach offers significant cost savings in the long run due to increased production efficiency.

Using family or multi-cavity molds is a strategic way to optimize costs, especially for bulk production, by maximizing output without the need for multiple molds.

10. Use a Core Cavity Approach

The core cavity approach is a highly cost-efficient technique for injection molding. In this approach, the mold material is shaped around a solid core, which ensures consistency and accurate duplication of intricate features. It simplifies the molding of tall walls and ribbed surfaces, eliminates the need for steep draft angles, and results in smoother surface finishes. It is especially beneficial for complex interior parts, such as those found in electronic housings. Additionally, it improves venting and enhances the ejection process, leading to a more efficient and cost-effective production method.

11. Modify and Reuse Mold

Modifying and reusing existing molds can significantly reduce costs in injection molding. Since it is easier to remove metal from an existing mold than to add more, careful planning can allow the same mold to be used for multiple iterations of a part design. Instead of purchasing new molds for every revision, start with a basic design, and then re-machine the mold to accommodate additional features or larger parts. This approach can save a substantial amount on tooling development.

Incorporating a quick-mold change system can further optimize the process. Using tool inserts or methods like MUD tooling, which allows a smaller mold to be inserted into an existing base, is another cost-effective way to reuse molds and save on tooling expenses.

12. Use Overmolding

Consider overmolding as an option for cost savings. While it might have higher upfront costs, it can reduce expenses down the line. For example, overmolding a gasket directly onto a part may initially cost more but eliminate manual installation costs later.

Reducing injection mold costs doesn’t have to be a complex challenge. By applying the tips we’ve discussed, you can start saving right away and improving your process efficiency. If you’re looking for even more insights into how to calculate injection molding mold cost, check out our previous article on how to lower injection molding costs.

Finding the right balance between cost-saving strategies and maintaining high-quality standards is key. ERYE specializes in helping businesses just like yours navigate these challenges and optimize their production processes. Feel free to reach out to us with any questions or to get a custom quote—we’re here to help you achieve the best results for your projects.