In injection molding, a cavity is the hollow (negative) space inside a mold that defines the shape of each part. Each cavity can produce exactly one component per injection cycle. Intricately machined from hardened steel or aluminum, cavities withstand repetitive thermal cycling and abrasive forces. Precision in cavity design ensures dimensional fidelity and surface finish, mitigating defects such as warpage or sink marks. Cavities can vary in multiplicity and configuration, influencing cycle durations and throughput.

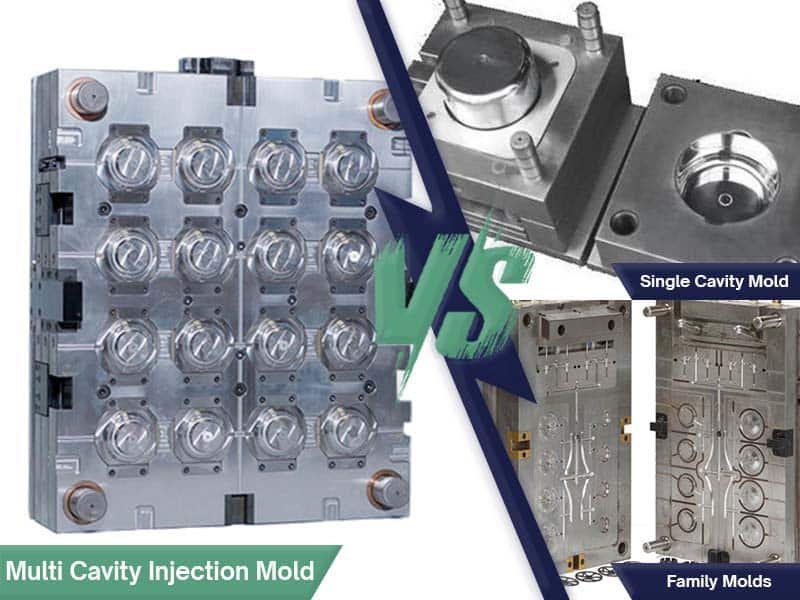

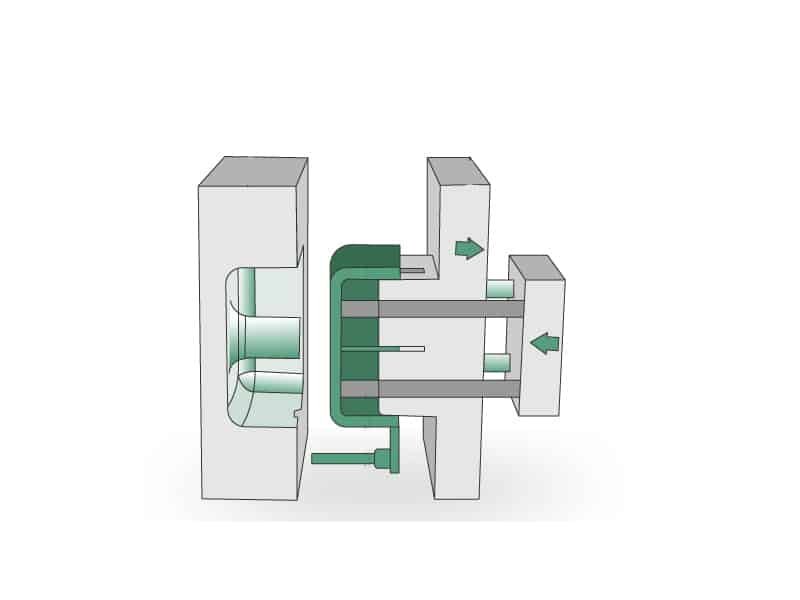

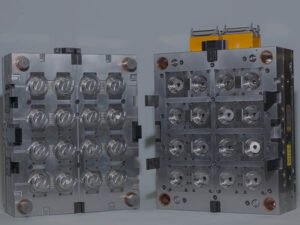

An injection mold’s cavity count directly influences production. A single-cavity mold will yield one component per shot, making it ideal for prototypes or low-volume runs. By contrast, a multi-cavity mold might have 2, 4, 8, or more cavities (up to dozens or even hundreds in large tools) so that it produces that many identical parts simultaneously. Family molds are a special case: they incorporate cavities for different parts in the same shot. In all cases, the injection molding process is the same, but the choice of mold type has a huge impact on cost, speed, and the nature of the output.

Single Cavity Mold

A single-cavity mold has exactly one cavity and thus produces one part per cycle. This simple tooling is fastest and least costly to build, making it a great choice for prototypes, low-volume production, or complex parts. Because only one part is made at a time, the process can be carefully controlled for high precision. For example, single-cavity tools are well suited to large or intricately detailed components (such as complex medical-device parts) where tight tolerances and thorough quality control are critical. They also allow the part design to be adjusted more easily; engineers often use a single-cavity mold to test a new product before investing in a larger multi-cavity tool.

Single-cavity molds do, however, have clear trade-offs. Because only one part is made per shot, production rates are slower and unit costs are higher for large batches. Any increase in volume must come from more cycles, which lengthens lead time. Nonetheless, for small runs, the low upfront cost and ease of control often outweigh these drawbacks.

Advantages of single-cavity molds

- Fastest to manufacture with the lowest tooling cost.

- Offers excellent process control and precision, ideal for complex or large parts.

- Provides flexibility to modify the design mid-run (useful for prototyping).

Disadvantages of single-cavity molds

- Only one part per cycle, so throughput is low.

- Higher cost per part at scale (since the mold cost isn’t amortized over many parts).

- Generally longer lead time for large orders.

Thus, single-cavity molding is best when volume is low or part quality is paramount. It is often chosen for initial runs or products that require frequent design changes.

Multi Cavity Mold

A multi-cavity mold contains multiple identical cavities in one tool, producing several identical parts in each cycle. This approach is favored for high-volume production where speed and efficiency are crucial. By molding many parts simultaneously, multi-cavity molds dramatically increase throughput and lower the cost per piece. For example, producing 100,000 parts in a single 8-cavity mold requires only 12,500 cycles instead of 100,000 cycles in a single-cavity mold.

However, multi-cavity molds carry higher complexity and risk. They take longer to design and fabricate (since precision is needed across all cavities) and they require a larger upfront investment in tooling materials and machining. Balancing material flow is critical: uneven filling can cause some cavities to underfill or overpack, leading to defects. Maintaining uniform processing conditions across all cavities is challenging and often requires careful runner and cooling design. If one cavity is flawed, it may spoil an entire shot (and potentially the whole tool needs repair).

Advantages of multi-cavity molds

- Higher production rate lowers the cost per part for large volumes.

- Better efficiency when making many small/simple parts.

Disadvantages of multi-cavity molds

- Much higher tooling costs and longer lead time to build the mold.

- More complex gate/runner systems and cooling to ensure even filling.

- Any variation affects all cavities simultaneously, so defects or changes can be very costly.

In practice, multi-cavity injection molding is chosen when volume demands are high. It is most cost-effective when the economy of scale (reduced per-part cost) outweighs the initial tooling expense.

Family Molds (Family Tooling)

Family molds (also called family molding or family tooling) combine multiple different cavities into one mold, molding several parts of an assembly in a single shot. For example, if a product has three distinct plastic components made of the same material (say, A, B, and C parts), a family mold would have three cavities of different shapes – one for A, one for B, and one for C – so that one cycle produces A+B+C together. This strategy is useful for small production runs of multi-part assemblies or where matching material/color among parts is important. For instance, household appliance components that must be color-matched often use family molds for color consistency. Family tooling can save time and cost by reducing the number of molding cycles and material waste.

However, family molds are technically demanding. Because each cavity is a different part geometry, the cavities often have different fill times and pressure requirements. This makes the mold very hard to balance. Poorly balanced family molds can have high defect rates (short shots or flash in some parts) because the plastic flows unevenly. It also complicates automation: after ejection, parts must be separated manually or with complex indexing, increasing labor. Importantly, if any part in a family mold is faulty or requires changes, the entire mold must be serviced – you can’t make just one component independently without retooling.

Advantages of family molds

- Produces all related parts in one shot, greatly reducing total cycle count.

- Ensures identical processing conditions (material batch, temperature) for all parts, which is ideal for matching colors or material properties.

- Can cut molding time and waste by combining steps.

Disadvantages of family molds

- Mold design is complex, each cavity must be balanced with runners/gates suited to its shape.

- Higher chance of defects due to uneven filling of differently sized cavities.

- More expensive and time-consuming to engineer; if one cavity or part is problematic, the whole mold (and entire production of all parts) is affected.

Family molds find niche use. They are particularly suited when all components of an assembly must be molded together or share strict appearance requirements. But because of the balancing and defect issues, it is not recommended to use family molds.

Choosing Single-Cavity, Multi-Cavity, or Family Molds

Selecting the right mold type depends on part design, production volume, budget, and project timing. There is no one-size-fits-all answer, but general guidelines emerge from industry experience. If you need only a few parts or you’re still perfecting the design, a single-cavity mold is usually best. It has the lowest risk and fastest turnaround for early-stage or low-volume production. If demand is high – for example, thousands or millions of parts – then multi-cavity injection molding can dramatically reduce your per-part cost and cycle time. Family molds are chosen when you must produce multiple distinct components together (often small runs of assemblies) or require exact matching across parts.

Other factors to weigh include part size and geometry. Very large parts may simply not fit in a multi-cavity layout, forcing a single-cavity approach. Complex parts with thick sections may need single cavities to allow proper cooling and filling. Conversely, tiny, simple parts can be ideal for multi-cavity molds since they cool quickly and easily fill multiple cavities. Material and finish requirements can also influence the choice: if you want perfect color consistency across several pieces, a family mold can guarantee all parts are made from the same melt batch.

In summary:

- Single-cavity is best for low-volume, high-precision work (e.g., prototypes, large or intricate parts).

- Multi-cavity is best for stable, high-volume runs of simple, identical parts (e.g,. commodities, consumer goods).

- Family molds are best for small to medium runs of multi-part assemblies that require synchronized production of different components.

Experienced mold designers will work with these factors to recommend the optimal strategy. At Erye molding, we know your market demand and perform DFM (Design for Manufacturing) upfront to minimize cost and risk.

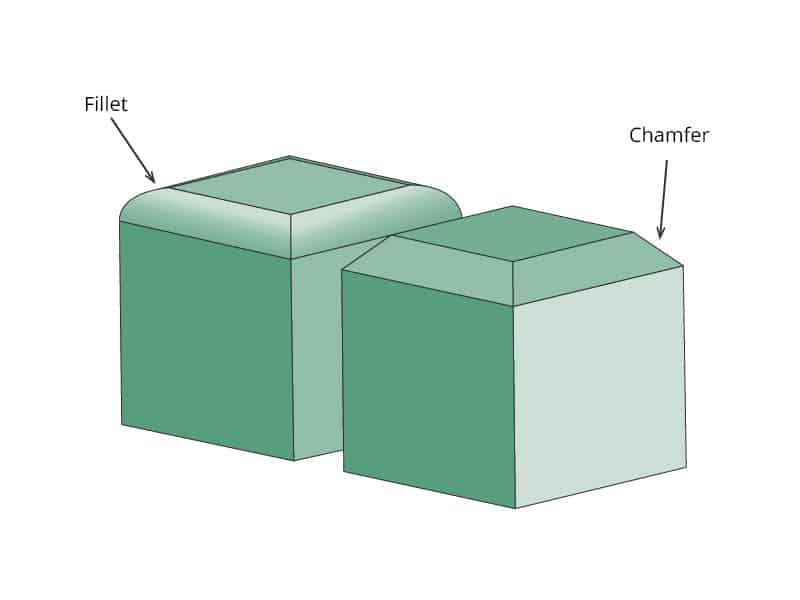

Designing With the Right Mold in Mind

Deciding on a mold type should happen early in the design phase, because cavity count and mold layout can dictate part geometry and features. Design-for-manufacturing (DFM) principles are crucial here. For instance, a part intended for a multi-cavity mold should be designed with uniform wall thickness and an easily balanced gate system across all cavities. Cavity spacing and runner design must allow even flow to each cavity, and the overall shot volume must match the injection machine’s capacity. In family molds, extra attention must be paid to the gating scheme and runners so that each distinct cavity fills at the right rate.

Given these trade-offs, it’s wise to consult with injection molding specialists during design. Tools like mold-flow analysis, shot-size calculators, and DFM checklists can help validate whether a proposed design is suited for the intended mold type. For example, if initial DFM review predicts that a family mold’s cavities will vary greatly in fill time, a designer might revise the part geometry or split it into separate molds. Aligning part design and mold design early avoids expensive changes later.

In the end, choosing between single-cavity, multi-cavity, or family tooling is about balancing production goals with tooling costs and complexity. By anticipating volume requirements, assembly needs, and quality targets during the design stage, you can ensure the mold type selected will meet both schedule and cost objectives.