Reaction Injection Molding (RIM), is a specialized manufacturing process tailored for producing plastic parts, particularly from thermosetting polymers. This comprehensive guide covers definitions, processes, materials, and comparisons, for RIM molding.

What is Reaction Injection Molding

Reaction Injection Molding, commonly abbreviated as RIM, is a manufacturing process where two or more liquid components are mixed and then injected into a mold. Inside the mold, these components undergo a chemical reaction, expanding and curing to form a solid part. This process is also known as Rim Molding, Rim Plastic Molding, or Reaction Injection Moulding (using British spelling). It is particularly suited for producing large, lightweight parts with quick cycle times, making it distinct from traditional injection molding, which typically uses thermoplastics.

RIM is noted for its versatility, capable of creating parts ranging from flexible to rigid and from solid to foamed structures. This flexibility is likely appealing to industries needing specific material properties, such as automotive for bumpers or medical for prosthetics.

RIM Molding Process

The RIM process can be broken down into several key steps. Here is the detailed step-to-step process.

Storage of Components

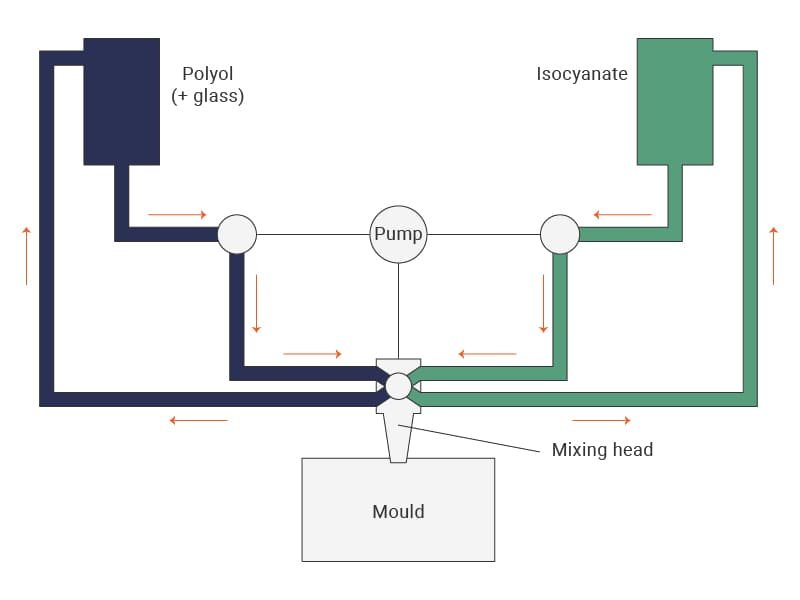

Liquid components, such as polyol and isocyanate for polyurethane RIM, are stored separately in tanks.

Mixing

Components are pumped through high-pressure lines to a mix head, where they are thoroughly mixed at high velocity.

Injection

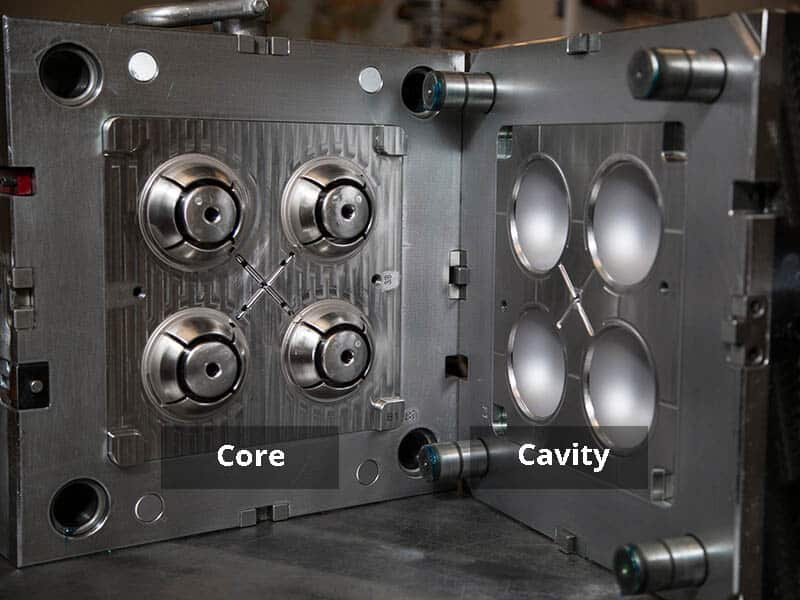

The mixture is injected into a closed mold at low pressure, allowing it to fill the cavity.

Curing

Inside the mold, the reactants react chemically, expanding to fill the mold and curing to form a solid part.

Demolding

After curing, the mold is opened, and the part is removed, with potential post-processing like trimming or painting.

This process, often referred to as the Rim Molding Process or Reaction Injection Molding Process, operates at lower temperatures than traditional methods, as it does not require melting the polymer. The low injection pressure used in RIM, also known as Rim Injection Molding, reduces the need for high clamping forces, potentially leading to smaller equipment and lower capital expenditures.

Advantages of Reaction Injection Molding

RIM injection molding offers several advantages, making it a preferred choice for certain applications:

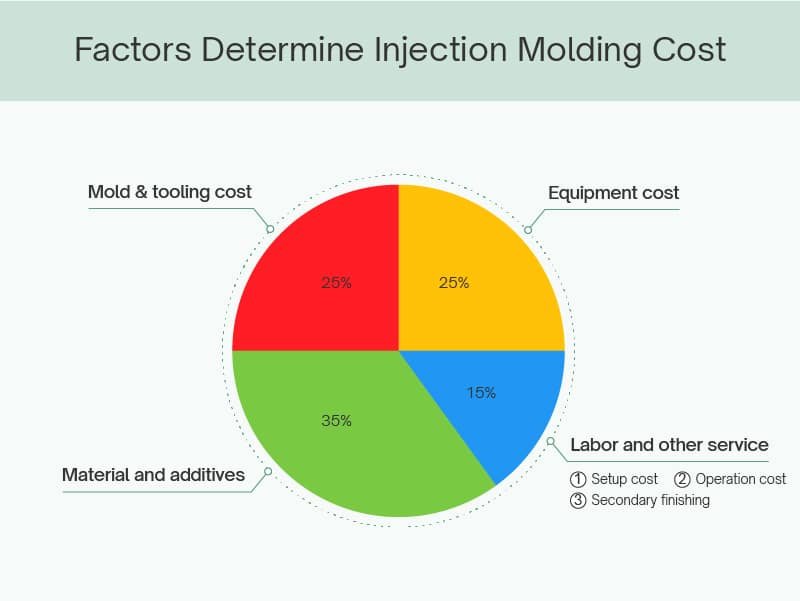

- Low Tooling Costs: RIM molds, often made from aluminum, are generally less expensive than the steel molds used in traditional injection molding, reducing initial investment.

- Fast Cycle Times: The chemical reaction forming the part is rapid, leading to quicker production cycles, which can enhance efficiency.

- Large Part Capability: RIM can produce very large parts, which might be challenging or impossible with other processes, due to the low viscosity of the mixture.

- Lightweight Parts: RIM parts can be designed to be lightweight, crucial for industries like automotive where weight reduction improves fuel efficiency.

- Complex Shapes: The process can handle complex geometries, suitable for parts with intricate designs, enhancing design flexibility.

- Good Surface Finish: RIM parts often have a good surface finish, reducing the need for additional finishing steps, which can save time and cost.

Materials Used in Reaction Moulding

The most common material in RIM is polyurethane (PU), with systems consisting of a polyol and an isocyanate that react to form the polymer. Other materials include:

- Polyureas

- Polyisocyanurates

- Polyesters

- Polyphenols

- Polyepoxides

- Nylon 6

Each material offers unique properties, and the choice depends on the part’s specific requirements. For instance, polyurethane RIM parts can be formulated for flexibility or rigidity, with varying densities and hardness levels. In the context of Reaction Injection Moulding, or RIM, the selection of material is crucial for achieving desired part properties.

Comparison with Traditional Injection Molding

Traditional injection molding, used for thermoplastics, involves melting the material, injecting it into a mold, and cooling it to form the part, which can be remelted and reformed. In contrast, RIM, or Rim Reaction Injection Molding, uses thermosetting polymers that undergo a permanent chemical reaction, cannot be remelted, and operate at lower temperatures.

Key differences are summarized in the following table:

| Aspect | Traditional Injection Molding | RIM (Reaction Injection Molding) |

|---|---|---|

| Material Type | Thermoplastics | Thermosets |

| Processing Temperature | High (melting required) | Low (chemical reaction) |

| Mold Pressure | High | Low |

| Part Size | Better for smaller parts | Suitable for larger parts |

| Cycle Time | Slower for large parts | Faster for large parts |

| Tooling Costs | Higher (steel molds) | Lower (aluminum molds) |

Except for reaction injection molding, there are many other types of common injection molding processes.

While traditional injection molding is better suited for high-volume production of smaller parts, RIM excels in producing larger parts or those requiring specific thermoset properties, offering a complementary approach for manufacturers.