Molded threads are all around us—from soda bottle caps to the nuts under a kitchen sink, and even the specialized screws in children’s playsets. These everyday parts are often mass-produced in multi-cavity, highly automated molds that take months to design and can cost hundreds of thousands of dollars.

A well thread design is essential because it directly affects strength, precision, and ease of assembly. Poorly designed threads can strip, fail under load, or cause assembly issues, even when made from strong materials. On the other hand, a properly engineered thread ensures durability, smooth engagement, and reliable performance, minimizing manufacturing defects and part failures. In short, good thread design turns potential weak points into dependable connections.

Production Methods for Plastic Threads

There are three primary techniques to produce threads in injection molded plastic parts.

1. Molded Threads

The threads are directly molded in during the injection process. This method is highly efficient for high-volume runs, but it demands precise mold design and involves complex components. It is the most challenging method to engineer than others.

2. Machined Threads

This method requires secondary machining. A smooth plastic boss is pre-made by molded, and threads are machined by CNC machining. This method avoids engineering complex molds with threaded features, but it requires a secondary process and increases per-part cost.

3. Inserted Threads

Metal inserts (usually brass or steel) are embedded in plastic through insert molding or post-molding processes such as hot riveting, ultrasonic embedding, or press fitting. The metal inserts provide greater strength and durability, making them ideal for parts that require repeated assembly. However, the additional components and processing steps also increase production complexity and cost.

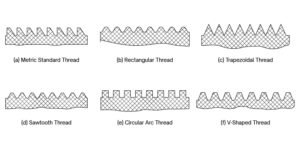

Types of Molded Threads Profiles Types

Molded-in threads can take on six common profile shapes. It’s advisable to avoid excessively fine metric threads, especially in fiber-filled plastics. Fine teeth tend to be filled by weaker pure resin at the tips, compromising the connection strength. It is recommended to choose a rougher, more robust thread shape to ensure reliable performance.

- Metric Standard Thread: Both the crest and root are cylindrical; this is the most widely used for plastic connections.

- Rectangular Thread: With its flat-topped, square profile, this variant is simple yet effective for certain applications.

- Trapezoidal Thread: Known for its trapezoid-shaped outline, this profile offers good load-bearing capability and efficient power transmission.

- Sawtooth Thread: Featuring asymmetric flanks, it excels in self-locking and unidirectional load resistance.

- Circular Arc Thread: With smoothly rounded crests and roots, this profile minimizes stress concentration and is commonly used in bottle necks and caps.

- V-Shaped Thread: Characterized by sharp angles, these are less common in plastics. It is only used on accessories connected to metal parts in certain scenarios.

Best Practices for Molded Threads Design

Thread Size and Structure Design

Threads were originally designed for metal parts and were standardized long before plastic injection molding became mainstream. This has created some challenges for plastic part designers. Therefore, designing molded threads requires careful consideration. Here are key design points to ensure that your injection-molded threads are strong, functional, and easy to produce.

Thread Diameter: External threads should not be too small. Typically, the major (outer) diameter should exceed 4 mm. Internal threads also require sufficient size; the minor (inner) diameter should generally be greater than 2 mm.

Thread Pitch: The pitch of molded threads usually should be at least 0.75 mm to maintain strength and manufacturability.

Thread Fit: When pairing plastic threads with metal threads, the engagement length is typically about 1.5 times the thread diameter, but generally should not exceed 12 mm.

Positioning of Threaded Holes: A threaded hole in a plastic part should be positioned such that its distance from the nearest edge is at least 1.5 times the outer diameter of the thread, and also greater than half of the wall thickness of the part.

Transition Zones: Both the start and end of a thread should include an unthreaded transition section. This helps prevent fuzzing or tearing of the plastic when the threaded component is unscrewed.

Thread Strength: Plastic threads are inherently weaker than their metal counterparts. It is recommended to design larger thread sizes to ensure adequate strength and durability.

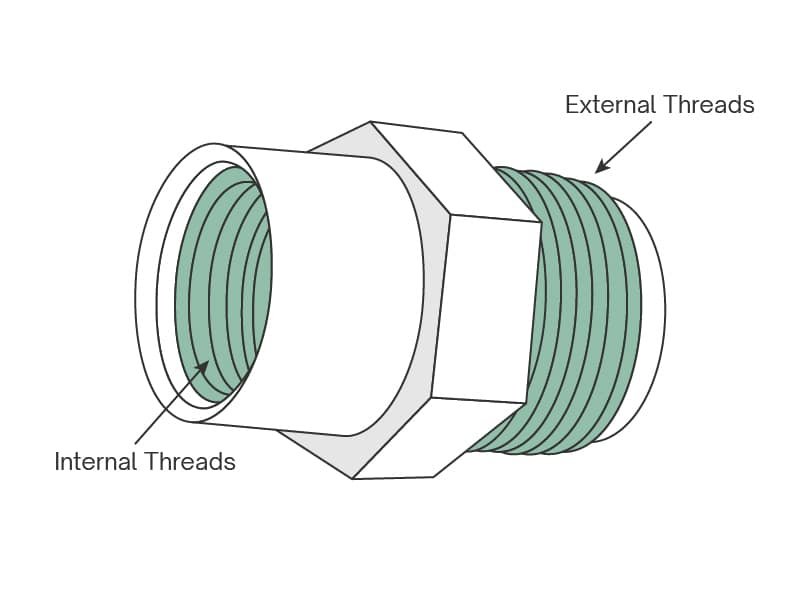

Internal and External Molded Thread Design

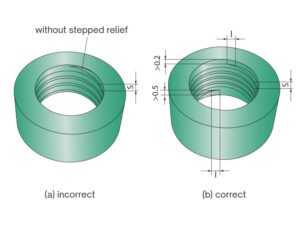

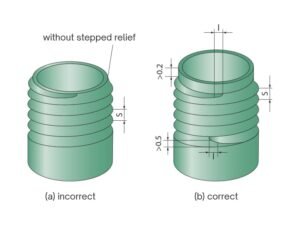

To prevent the outermost thread in a plastic threaded hole from chipping or deforming, it is advisable to incorporate a stepped relief at the start of the internal thread. This step should be between 0.2 and 0.8 mm in height, while the adjacent thread should smoothly rise from the relief.

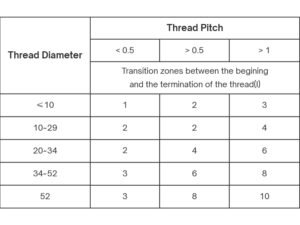

When designing plastic male threads, the starting end of the thread should taper down by at least 0.2 mm, and the end of the thread must not extend right up to the perpendicular base surface to avoid root-level fractures. Moreover, both the beginning and the termination of the thread should include smooth transition zones. The dimensions for these transition zones (denoted as l) can be found in the accompanying table.

Add Draft Angle for Easy Demolding

A draft angle of 1° to 2° should be used to ensure easy part ejection for both internal and external threads. For surfaces with textures, add another 1° to 2° to counteract increased friction during ejection.

Material Selection for Molded Threads

For durable and clean thread features, favor plastics that meet both mechanical and molding-specific requirements. Internal threads benefit from materials with better moldability and resilience, such as ABS, POM (Delrin), or Nylon. Avoid glass-filled and high-temp materials; such limitation exists for external molded threads.

Parting Lines Molded Threads

External threads can be molded with the parting line running along the thread centerline, though it may leave minor imperfections or flash near the thread root. Internal threads, on the other hand, often require complex molds with unscrewing mechanisms or collapsible cores to cleanly release the part without damaging the threads.

Consistent Wall Thickness

Ensure uniform and adequate wall thickness; non-uniform walls can lead to sink marks, warpage, trapped air, or weak thread roots. If thicker sections exist around threads, integrate smooth transitions.

Read our blog: Injection Molding Wall Thickness Design Guide.

Injection Molding Thread Alternatives

While molded threads are a direct solution for fastening in plastic parts, they are not always the most efficient or cost-effective choice. When thread molding is complex, prone to wear, or increases tooling costs, consider using alternative fastening methods.

Designing threaded bosses is fairly straightforward: a reinforced cylindrical feature designed to accept a self-tapping screw or insert, but attention should be paid to proper dimensions, wall thickness, and draft angles to ensure strong joints and minimize cosmetic issues.

You are also not limited to standard thread profiles from reference guides. In fact, many high-volume consumer products—like peanut butter jar lids or beverage bottle caps—use customized thread forms that are optimized for their specific application. If your design does not need to mate with off-the-shelf components, exploring non-standard thread forms can open the door to improved performance and easier manufacturing.

Conclusion

Designing threads for plastic injection molding requires balancing functionality, manufacturability, and cost. From selecting the right thread form and dimensions to considering alternatives like screw bosses or inserts, thoughtful design choices can prevent failures, reduce tooling complexity, and improve assembly efficiency.

Successful plastic thread design comes down to smart engineering, the right materials, and knowing when a molded thread isn’t the only—or best—option.