Off topic, but a fun fact: When you look at a plastic bottle cap under bright light, you will notice faint lines running through it. Those aren’t cracks. They’re injection molding weld lines. And they’re one of the most common defects in plastic injection molding.

What is a Weld Line in Injection Molding?

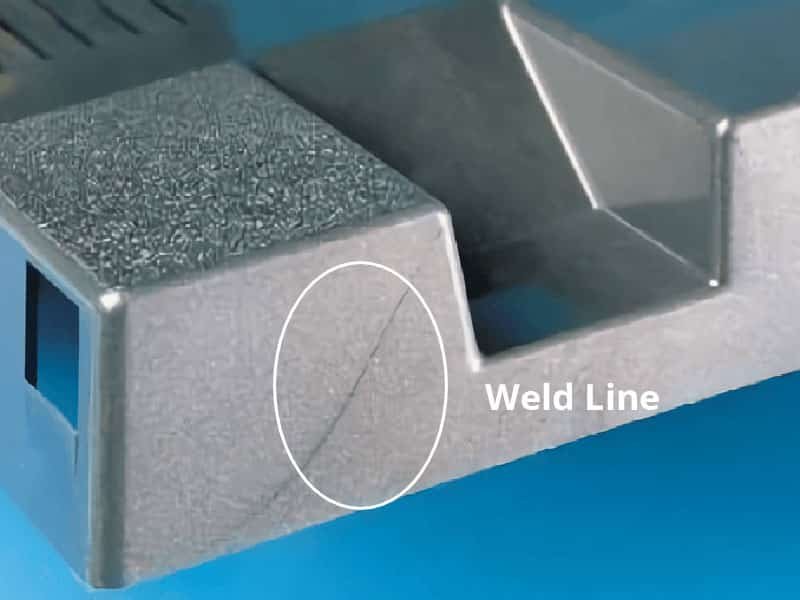

You need to understand that an injection molding weld line is a visible line or seam on an injection molded plastic part. It forms when two separate flows of molten plastic meet and rejoin inside the mold cavity. The plastic enters the mold cavity through an opening called a gate. As the material flows, it will split around holes or obstructions. When these two flow fronts meet again, they create a weld line.

The weld line in injection molding is essentially where two melt fronts merge back together.

This defect appears as a thin, hairline mark on the surface of your product. Sometimes it’s barely visible. Other times it stands out like a scar. Either way, it’s a cosmetic issue that can hurt your plastic product quality.

Why Injection Molding Weld Lines Occur?

Weld lines in plastic occur when two flows of plastic meet during the molding process. Here is what happens inside the mold: Hot plastic shoots into the cavity. The flow front moves forward. When it hits an obstruction like a hole or an insert, the flow splits. Two different streams now flow around the obstacle. On the other side, these fronts meet again.

The problem? By the time they reconnect, the material has started to cool. The two flow fronts may not fuse together more completely. Instead, they just touch and solidify. That’s your weld line.

Weld lines occur when two separate flows cool too quickly before bonding. The flow fronts may have dropped below the glass transition temperature for amorphous plastics. For semi-crystalline polymers, the temperature drop affects how well the chains meld back together.

You’ll find weld lines in injection molded plastic parts with these features:

- Multiple gates that create separate flows

- Holes that force the plastic to flow around them

- Complex part design with varying wall thickness

- Areas where flow continues but splits naturally

Weld Lines in Injection Molding vs Regular Flow Lines

Do not confuse weld lines in plastic with regular flow lines. Flow lines are surface patterns that show the direction of plastic flow. They’re mostly cosmetic. Weld lines in injection molding are different. They can actually weaken the part. Read more: Injection Molding Flow Lines: Troubleshooting and Solutions.

An injection molding weld line forms when two melt fronts meet at an angle greater than 135 degrees. The fronts fuse together better at wider angles. When the angle is less than 135 degrees, you get a true weld line. That’s when strength becomes a real concern.

How Weld Lines Affect Your Plastic Part

A weld line is more than a visible flaw. It causes a severe drop in the molded part’s strength.

Cause of Weakness

This structural defect occurs because polymer chains fail to bond correctly where two flow fronts converge. The chains at the front edge cool and orient early. When the fronts meet, they cannot fully interlock. This leaves an incomplete, stress-vulnerable bond, leading to breakage at the weld under load.

Affecting Strength Loss

Weld line strength can fall by 30% to 80%. This loss depends on several factors:

- Pre-Meet Cooling: Plastic temperature at convergence.

- Angle of Contact: How the flow fronts meet.

- Material Choice: The specific polymer used.

- Process Settings: Injection speed, pressure, and melt temperature.

For structural parts, this strength reduction is a critical failure point. Unreliable parts cannot be sold.

Types of Weld Line Imperfections

Defects range from superficial to severe structural failure.

Cosmetic:

- Visible Line: A surface mark, color change, or slight recess.

Structural:

- Part Failure: Breakage under applied load.

- Low Impact Resistance: Fragility in the weld area.

- Incomplete Fill: Voids near the meeting point.

- Stress Concentration: The V-notch effect.

- Compounding Flaws: Interaction with other defects, like sink marks.

Poor mold design or incorrect processing amplifies the defect. Bad gate placement lengthens the flow path. This increases cooling, resulting in a weaker, more visible weld line.

How to Avoid Injection Molding Weld Lines

You can’t always eliminate weld lines entirely. But you can minimize them. Here’s how to avoid weld lines in injection molded parts.

Change the Gate Location

Moving the gate changes where two flows meet. You want to move the weld line to a non-critical area. Put it somewhere you can hide it. Or move weld lines to a spot where strength doesn’t matter as much.

Sometimes using multiple gates helps. Other times, change the gate to a single point. It depends on your part geometry. Computer simulation during DFM (design for manufacturability) shows you where weld lines will form before you cut steel.

Improve Part Design

Part design is your first defense. Remove unnecessary holes if possible. Make the flow path simpler. Reduce the wall thickness ratio between thin and thick sections.

Uniform wall thickness helps plastic flow smoothly. The melt front stays hot longer. When two fronts do meet, they’re still above the critical temperature for good bonding.

If you must have holes, position them carefully. Think about the flow pattern. Can you move a hole slightly to change where the flows merge?

Optimize Mold Design

Mold design controls how plastic moves through the cavity. Add venting where two flow fronts meet. Trapped air prevents proper bonding. Good vents let that air escape so the fronts can fuse together more completely.

Consider sequential valve gating. This lets you control when different parts of the mold fill. You can ensure one flow dominates instead of having two flows of equal strength meeting head on.

Raise the mold temperature in the weld line area. A hot mold keeps the plastic above its glass transition temperature longer. The flow fronts stay fluid enough to bond properly.

Adjust Processing Parameters

Increasing the temperature helps reduce weld lines. Raise the melt temperature so the plastic stays hot longer. The machine needs to inject material that’s fluid enough to bond when flows merge.

Boost injection speed to reduce cooling time. Fast injection means the second front arrives before the first front has cooled too much. The two melt fronts can still merge properly.

Increase packing pressure after the cavity fills. Extra pressure forces the material together at the weld line. It helps compensate for incomplete bonding.

Adjust the injection molding process cycle time. Sometimes a slower cycle helps. The mold stays warmer between shots.

Select the Right Material

Different plastics behave differently. Amorphous polymers generally create less severe weld lines than semi crystalline materials. That’s because amorphous plastics have a wider processing window.

Some materials have additives that improve flow. Better viscosity means the plastic stays fluid longer. The fronts meet while still hot enough to bond.

Consider the plastic material properties for your application. If strength at the weld line is critical, test different resins. Some perform much better than others.

Advanced Molding Techniques to Avoid Weld Lines

- Hot Runner Systems: These systems keep the plastic molten. The melt stays hot right up to the gate. This avoids cold runners. Less cooling happens before the cavity fills.

- Gas Assisted Injection Molding: This method can remove some weld lines. Gas pushes through the thick part’s center. It completely changes the flow pattern.

- Variotherm Molding: Rapidly heat the mold surface. This happens before injection. After filling, cold water cools it fast. The hot surface stops premature solidification. This nearly eliminates visible weld lines on Class A surfaces.

- Ultrasonic Welding: Weld lines are strengthened after molding. This is an extra process. It is used for critical needs. Weld line strength must equal the base material.

Strict Testing and Quality Control

Don’t assume weld lines are fine. Test your injection molded part under real operating conditions. Apply stress directly across the weld line.

Measure the impact strength in the weld line area. Compare this result to samples without weld lines. This comparison reveals the defect’s impact on your application. A 20% strength drop may be okay sometimes. Other times, you need 100% strength retention.

Use quality control to stop bad parts from shipping. Visual inspection is for cosmetic problems. Mechanical testing catches structural weaknesses caused by weld lines.

When Weld Lines in Plastic Don’t Matter

Not every plastic part needs perfect aesthetics or maximum strength. Sometimes, weld lines are completely acceptable. A housing that’s hidden inside a product doesn’t need Class A surfaces. An over-molded part where rubber covers the plastic can hide any lines.

For non-structural components, a visible weld line will be fine. Just make sure these parts are according to the requirements of injection molding parts procurement specialist. Set clear expectations during product design.

The Bottom Line on Injection Molding Weld Lines

Weld lines in injection molding are a common challenge. They form when two flows meet. The plastic has cooled too much to bond completely. The result is a visible line that can weaken your part.

You can minimize the defect through smart part design, optimized mold design, and proper processing. Change gate locations to move weld lines to non-critical areas. Increase the melt temperature and injection speed to keep the plastic hot. Add venting so trapped air doesn’t prevent bonding.