Surface finish in injection molding is a critical design consideration that significantly impacts both the aesthetics and functionality of the final product. Surface finishes can range from non-cosmetic textures to high-gloss polishes, and the choice depends on factors such as the part’s end-use application, material selection, and production stage. In this post, we will introduce injection molding surface finish standards, types, and factors to consider when selecting the appropriate finish for your project.

What Are Surface Finishes in Injection Molding?

Injection molding surface finish refers to the texture or smoothness imparted to the surface of a molded plastic part. These finishes are achieved through various methods applied to the mold cavity, such as polishing, texturing, or etching. The surface finish can range from a mirror-like gloss to a matte or textured appearance, depending on the product’s specific requirements.

Injection Molding Surface Finish Standards

Surface finish in injection molding standards provides a consistent way to specify and measure the surface quality of molded parts. The most recognized standards in the industry include SPI, VDI, and Mold-Tech.

SPI (Society of Plastic Industry) Standards

The SPI (Society of Plastics Industry) standards, now under the Plastics Industry Association (PIA), are widely accepted in the injection molding industry. They provide a standardized way to describe the surface finish of molded plastic parts, facilitating communication between designers and manufacturers. These finishes are grouped into four main categories: A, B, C, and D.

Glossy (A): This includes three sub-grades (A-1, A-2, A-3) that provide a highly polished surface, suitable for optical applications and parts requiring a mirror-like finish.

Semi-Glossy (B): This includes sub-grades (B-1, B-2, B-3) that offer a good visual appearance without the high gloss, appropriate for parts that do not require a reflective surface.

Matte (C): Comprising sub-grades (C-1, C-2, C-3), this finish is used for parts where a low visual appearance is acceptable, but machining marks must be eliminated.

Textured (D): This includes sub-grades (D-1, D-2, D-3) that provide a satin or dull finish, often used for parts requiring a non-slip surface or specific tactile properties.

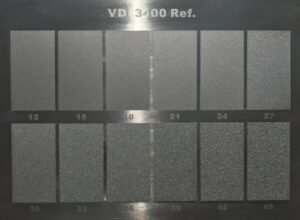

VDI (Verein Deutscher Ingenieure) Standards

The VDI standards, particularly VDI 3400, are recognized primarily in Europe. They focus on surface roughness and texture, often achieved through electrical discharge machining (EDM). These standards are crucial for applications requiring precise surface quality and are frequently used by toolmakers across North America, Europe, and Asia.

Mold-Tech Standards

Mold-Tech standards provide a range of surface finishes categorized by texture and gloss levels. These standards are often used in conjunction with SPI and VDI standards to achieve specific aesthetic and functional requirements in molded parts.

Common Types of Surface Finish in Injection Molding

Surface finishes in injection molding are essential for enhancing the aesthetics and functionality of molded parts. The main types of finishes include high-gloss, semi-gloss, matte, and textured finishes, each serving specific applications and achieved through various techniques.

High-Gloss Finishes in Injection Molding

High-gloss finishes are characterized by their shiny, reflective surfaces, making them ideal for applications where visual appeal is paramount, such as in consumer electronics (e.g., smartphone casings, television panels).

Methods of Achieving This Type:

- Diamond Polishing

- Heat and Injection Parameters

Semi-Gloss Finishes

Semi-gloss finishes offer a balance between gloss and matte, providing a clean appearance while hiding minor imperfections. They are commonly used for parts that don’t require a high-gloss look but still need to look polished. Such as automotive interiors and appliances, where a refined appearance is desired without the reflective quality of high-gloss finishes.

Methods of Achieving This Finish:

- EDM Spark Erosion

Matte Finishes

Matte finishes are popular for their non-reflective quality and cost-effectiveness. They are often preferred in applications where glare reduction is important. Matte finishes are widely used in consumer products and automotive components, as they provide a sophisticated look while being more forgiving of surface imperfections.

Processes to Achieve a Matte Finish:

- Abrasive Stoning

Textured Finishes

Textured finishes enhance the grip and aesthetic appeal of molded parts, making them suitable for applications where tactile feedback is important. Textured surfaces are commonly found in automotive interiors, hand tools, and consumer electronics, where a non-slip surface is beneficial. Interior panels in vehicles often utilize textured finishes to provide a premium feel and improve grip. Additionally, textured finishes can help paint adhere better to surfaces compared to glossy finishes, making them ideal for painted components.

Methods to Achieve a Textured Finish

- Bead Blasting

- Sanding and Polishing

- Electrical Discharge Machining (EDM)

- Chemical Etching

- Laser Etching

Factors Affecting Injection Molding Surface Finish

Selecting the appropriate surface finish for an injection-molded part is a critical decision that impacts both the product’s performance and manufacturing efficiency. Several factors must be considered to ensure the chosen finish meets all design and functional requirements.

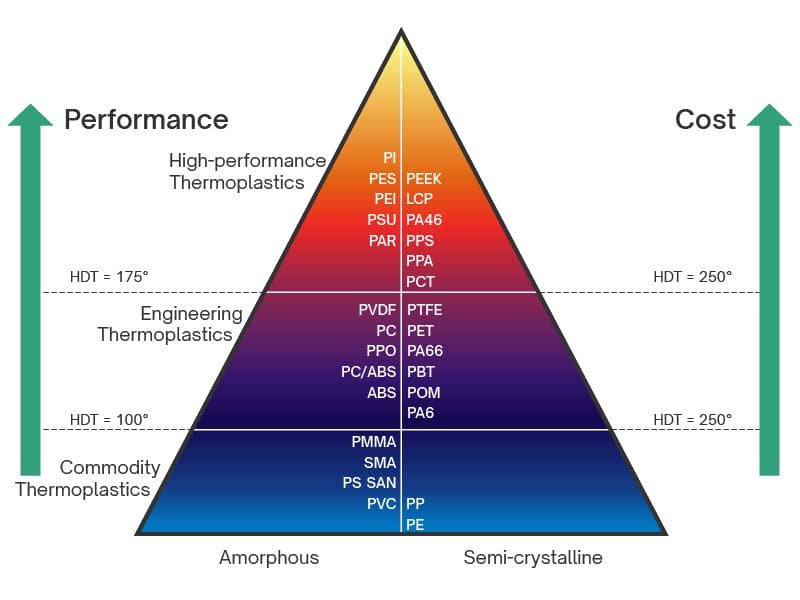

1. Material Type

Different plastics have unique properties that affect how they respond to surface finishes. For example:

- ABS (Acrylonitrile Butadiene Styrene): ABS is versatile and can achieve a wide range of finishes, from glossy to matte. Its ability to be easily textured.

- PC (Polycarbonate): Polycarbonate is known for its clarity and impact resistance. It is often used for parts requiring high-gloss finishes, like optical components or clear housings.

- PP (Polypropylene): Polypropylene has a lower surface energy, making it less responsive to certain textures or high-gloss finishes. It’s commonly used for parts where a matte or lightly textured finish is acceptable.

2. Product Design Requirements

The visual appearance of the product plays a significant role in surface finish selection. Products intended for consumer use often require finishes that enhance their aesthetic appeal, such as high-gloss or matte finishes that align with brand identity.

The design’s complexity can limit the choice of surface finishes. Intricate designs with tight corners or undercuts may be challenging to polish or texture uniformly, requiring specific finishes that can be applied effectively across the entire part.

3. Functionality

Grip: Surface finishes can be selected to enhance the grip of the product. Textured finishes, such as those from the SPI D-series, are often chosen for handles, grips, or parts that need to resist slipping.

Appearance and Light Reflection: The level of gloss and texture affects how light interacts with the part. High-gloss finishes reflect light, making the product appear shiny and smooth, while matte finishes scatter light, reducing glare and creating a softer look.

Durability and Wear Resistance: The chosen surface finish must withstand the intended use environment. For instance, parts exposed to frequent handling or abrasive conditions may require a durable matte or textured finish that can resist wear and tear.

4. Cost Considerations

High-gloss finishes require extensive polishing, which can be time-consuming and expensive. Textured finishes may require additional mold treatments, such as chemical etching or sandblasting, adding to the overall cost.

The surface finish can influence the mold cycle time. For example, highly polished molds may result in longer cooling times, affecting production throughput. Balancing the desired finish with efficient production is key to controlling costs.

5. Post-Molding Processes

Post-molding processes can further refine the surface finish of molded parts and include techniques such as painting, polishing, and coating.

Painting: This process not only improves aesthetics but also adds a layer of protection against environmental factors. Techniques such as spray painting, powder coating, or electrostatic painting can enhance the durability and visual appeal of the final product.

Polishing: Polishing can be used to achieve a high-gloss finish, enhancing the part’s appearance and reducing surface roughness. This is particularly important for parts requiring optical clarity or a premium look.

Conclusion

Selecting the right surface finish for injection-molded parts is a critical aspect of product design and manufacturing. As we have explored, there are different injection molding surface finish standards and types, and several factors that impact the selection of surface finishes, including material choice, design specifications, and post-molding processes. Each of these elements must be carefully considered to achieve the desired outcome. Thoughtful consideration of surface finishes can transform a good product into a great one, making it essential for anyone involved in the design and manufacturing processes to prioritize this crucial aspect.