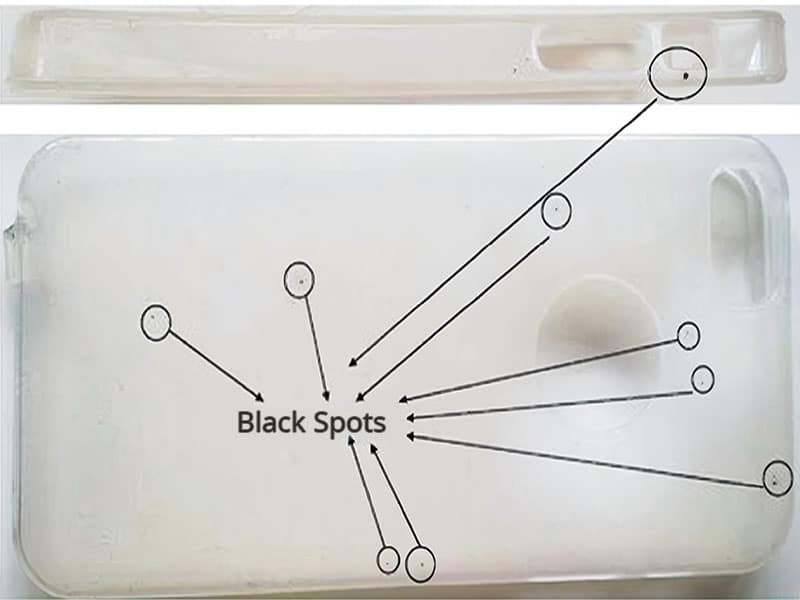

Black spots on plastic, and black specks are common visual defects in injection molding, appearing as concentrated blackening in specific areas. It often appears near weld lines, black ribs, protruding parts, or at the end of the flow in local corner positions. The black spots on plastic can also appear irregularly without a specific pattern.

They are not usually severe enough to affect the product’s functionality. Black spots or black lines are classified as a cosmetic defect, affecting appearance rather than performance. The product can be accepted using a limit sample, which serves as a reference showing the maximum allowable defect level, or by establishing specific inspection standards. These standards are generally formulated based on two key metrics: the size of the black spots and the number of black spots on the same surface.

When there are black spot and black speck on the product, first look at the production environment and whether the plastic material used for production is clean, then check whether the defects appear in a fixed position or periodically, and finally confirm the specific cause. In general, there are four main reasons that caused black spots in plastic:

- Production environment

- Material

- Mold design and maintenance

- Injection machine

Following is a detailed chart explain the causes and solutions of black spots on plastic.

| Causes | Solutions |

|---|---|

| Production environment factors | |

| The injection cylinder has been used to produce different materials over an extended period, and temperature fluctuations have led to oxidation and degradation of the materials. | For materials that have been in the injection cylinder for a long time, either remove them or reduce their temperature to minimize degradation. |

| During the cleaning process, the original low-temperature materials were not completely removed from the cylinder. When the operating temperature is increased, these low-temperature materials (such as fire retardants and additives) cannot withstand the heat and decompose. | Ensure that the entire machine, especially the injection cylinder is thoroughly cleaned after changing materials to prevent any contamination from affecting the new material. |

| Meterial factors | |

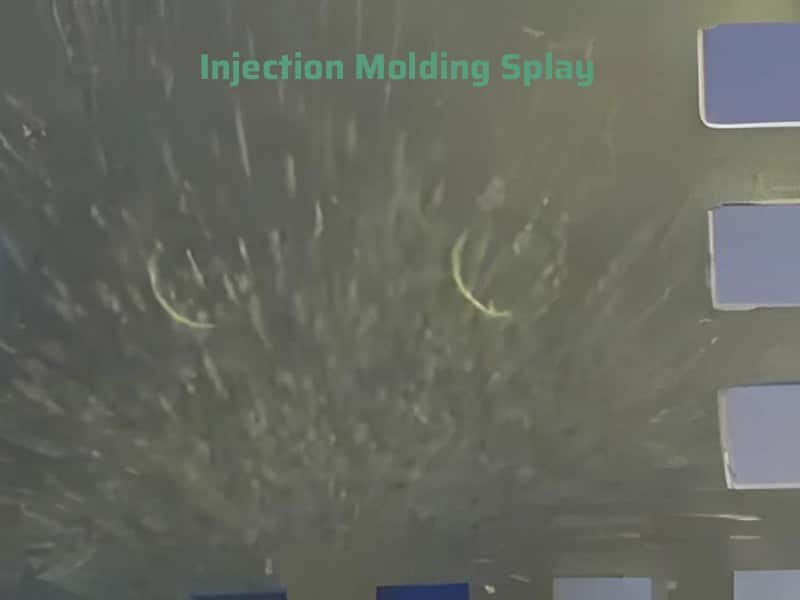

| Not added enough lubricants in some material, it can cause frictional heat, leading to gas buildup. If these gases aren't vented properly, they can burn, creating black specks or spots in the final product. | Change the material formular to ensure enough lubricant is added. |

| The raw material can’t handle the operating temperature, it breaks down, causing defects. | Use a material that can withstand higher temperatures. |

| Mold design and maintenance factors | |

| The gates design are too small or too rough that generate significant friction heat. Poor venting can lead to gas combustion and resulting in black specks. | Enlarge the gates and polish their surfaces to reduce frication and heat, improving mold venting to prevent gas combustion. |

| The worn out guide pins and guide bushings produce iron fillings that fall into the cavity. | Regularly maintain the mold and add lubricants to prevent wear and tear of guide components. |

| Injection machine factors | |

| The nozzle's hole is too small or its inner surface is too rough, generating a lot of friction heat. | Enlarge the nozzle's aperture and polish its inner surface. |

| The material cylinder (barrel) or feed hopper is worn, cracked, or bent, causing parts of the polymer to overheat and produce black specks | Replace teh relevent parts of the injection machine |

If you are unable to solve the issue right away, Erye Molding has experience with identifying injection defects and processing defects. Contact our team or request a quote to start your injection molding project today!