What is Insert Molding?

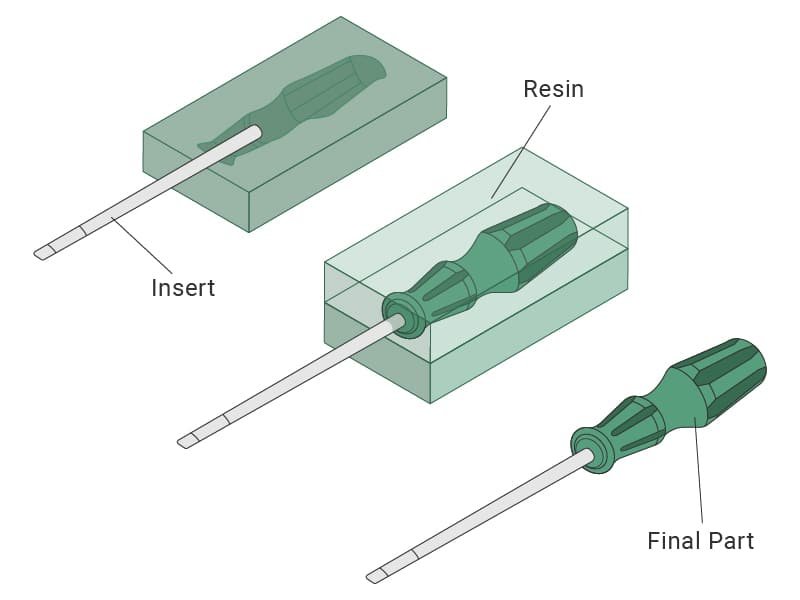

Insert molding is a sophisticated manufacturing process where a pre-formed insert, typically made of metal, plastic, or ceramic, is placed into a mold cavity and then encapsulated with a plastic material, or sometimes an elastomer rubber material. The process combines the benefits of injection molding with the strength and durability of the insert, creating a final part that features both the desired plastic exterior and a solid insert core. Insert molding is widely utilized for producing parts that require additional strength, electrical conductivity, or specific properties that plastic alone cannot provide.

Insert Molding Process Overview

Overview of the Insert Molding Process

Insert molding begins by selecting and preparing the insert, which can be anything from a metal screw to a ceramic bushing, depending on the requirements of the part. The insert is placed into the mold cavity, where it is positioned securely to ensure accurate placement during the injection phase. Next, molten resin is injected under high pressure into the mold, surrounding the insert and forming the final part. The mold is then cooled, and once solidified, the part is ejected. This process provides a seamless bond between the insert and the plastic, offering enhanced durability and functionality.

What Are the Functions of Inserts in the Molding Process

Insert moulding combines the precision and efficiency of injection molding, and the added inserts enhance the mechanical, electrical, and thermal properties of the final parts. While injection molding focuses on forming parts entirely from molten plastic, insert molding incorporates additional materials (such as metal or ceramics) into the final product. The inserts in insert molding can provide reinforcement, conductivity, or create mounting joints for screws and fasteners.

The insert often serves as the load-bearing or functional core of the part, while the surrounding plastic provides flexibility, insulation, or a smooth surface finish. This integration of two materials in a single part reduces the need for secondary assembly and streamlines the production process. Proper insert placement is vital for ensuring the quality and strength of the bond between the insert and the molded plastic.

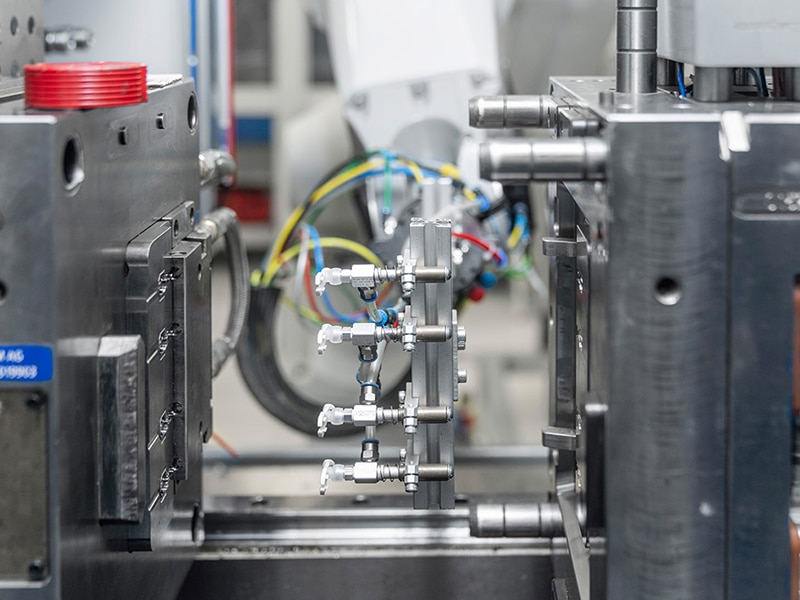

Equipment Required for Insert Molding

Insert molding shares the same machine as the injection molding process; both require an injection molding machine, which is used to inject molten plastic into the mold cavity. Additional components include the mold itself, which is designed to accommodate the insert, and fixtures that securely hold the insert in place during the molding process. A robot or automated system may also be used to handle the insert placement and part ejection. Other tools, such as temperature controllers and pressure sensors, are employed to ensure optimal molding conditions for both the insert and the surrounding material.

Types of Inserts in Insert Molding

Inserts play a pivotal role in enhancing the performance and functionality of molded parts. By adding inserts with specific properties—such as strength, electrical conductivity, or heat resistance, insert molding components can meet exacting standards for different industries. Inserts also help to simplify the design process by eliminating the need for multiple assembly operations, thereby improving overall part performance.

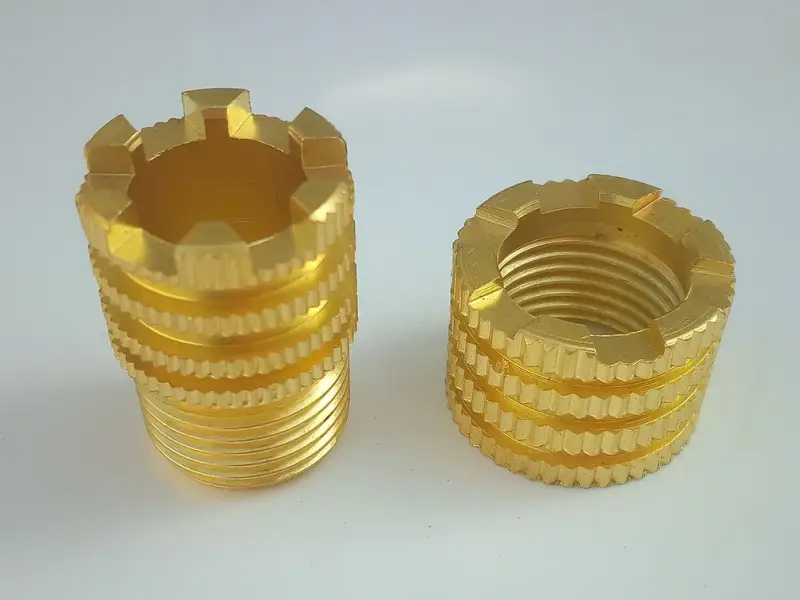

Metal Inserts: Benefits and Applications

Metal inserts are commonly used in insert moulding for their ability to enhance the mechanical strength and thermal conductivity of the final part. They are ideal for applications that require high strength, such as automotive components, fasteners, and connectors. Metal inserts also provide the necessary hardness and wear resistance for parts subjected to friction or high-impact conditions.

Plastic Inserts: Versatility and Use Cases

Plastic inserts are often used in insert molding when the primary objective is to enhance the functionality of the part without compromising the overall weight or cost. Plastic inserts are lightweight, versatile, and easy to process, making them suitable for a wide range of applications, from consumer electronics to medical devices. They are often chosen when the part needs to be electrically insulated or require resistance to chemicals.

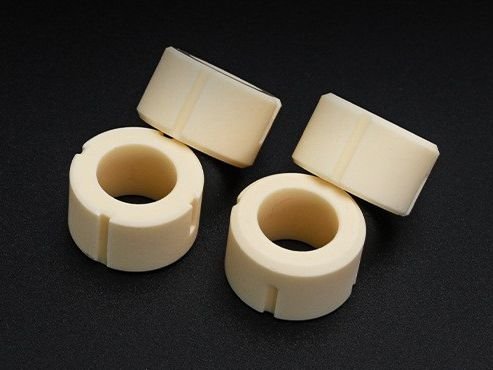

Ceramic and Other Specialized Inserts

Ceramic inserts are utilized when parts need to withstand high temperatures, extreme wear, or abrasive conditions. These inserts offer excellent thermal resistance and can be used in industries like aerospace and electronics. Other specialized inserts, such as graphite or composite materials, may also be used in insert molding to achieve specific material properties required for the end product.

Common Insert Molding Materials for Molding

The molding material, usually a thermoplastic or thermoset resin, is injected around the insert to create the final part. The material selected must provide adequate bonding with the insert while also meeting the mechanical and functional requirements of the finished product.

Thermoplastics for Insert Molding

Thermoplastics are the most commonly used materials for molding in the insert molding process. These materials are preferred because they can be easily injected into molds, offer good flow characteristics, and can be reprocessed.

- Polycarbonate (PC)

- Acrylonitrile Butadiene Styrene (ABS)

- Polypropylene (PP)

- Nylon (PA)

- Polyethylene (PE)

- Polyetheretherketone (PEEK)

- Polyoxymethylene (POM)

- Polyethylene (PE)

Elastomers and Rubbers for Insert Molding

Insert molding often involves the use of elastomers and rubbers to provide flexibility, cushioning, and high-performance bonding to metal, plastic, or ceramic inserts. Below are some of the most commonly used elastomers and rubbers in insert molding processes, particularly for bonding inserts to molded parts.

- Polyurethane(PU)

- TPE

- TPV

- TPU

- Silicone

- Neoprene (Chloroprene Rubber)

- Ethylene Propylene Diene Monomer (EPDM)

- Butyl Rubber (IIR)

- Fluoroelastomers (FKM)

- Nitrile Rubber (NBR)

- Styrene-Butadiene Rubber (SBR)

- Natural Rubber (NR)

Thermosets for Insert Molding

Thermoset plastics are typically used in applications where durability and resistance to high temperatures are required. Once cured, thermosets do not soften or melt, which makes them ideal for high-heat applications or parts that must maintain structural integrity at elevated temperatures.

- Epoxy

- Phenolic

- Melamine

Material Selection for Inserts and Molding Materials

Material selection for both the insert and the molding resin is critical to achieving part performance, longevity, and manufacturability. Poor choices lead to defects, premature failure, or expensive redesigns. Common insert materials include metals (such as stainless steel, brass, or aluminum), plastics, ceramics, and composites. These inserts are then combined with plastic materials like thermoplastics (ABS, polycarbonate, or nylon) or thermosets (phenolic or epoxy), depending on the required properties of the final part.

Carefully Choose the Insert Material Types

Common insert materials are stainless steel, brass, aluminum, copper, ceramics, and engineered plastics. The inserts need to be paired with plastic materials that will adhere securely to the insert without compromising the integrity of the final part. For example, stainless steel offers strength and corrosion resistance but is heavy and costs more; aluminum is lighter, good for heat dissipation, but may require surface treatment or plating to enhance adhesion.

Metal inserts, such as steel, require plastics like nylon or polypropylene for a secure bond, while plastic inserts may require elastomer materials for a more cost-effective and lighter solution. This synergy between materials is crucial in ensuring optimal performance and longevity of the molded part.

Molding Resin Selection & Performance

Common resins include thermoplastics (ABS, Polycarbonate, Nylon, PBT, PP) and sometimes thermosets (phenolic, epoxy) when high heat or dimensional stability is required. The resin must have a melting point and viscosity compatible with the insert and the mold cycle. Also, understand the shrinkage and cooling behavior of the resin to avoid warping or stress around the insert.

Thermal Expansion & Thermal Stability Matching

Inserts often have very different thermal expansion rates than molding plastics. If mismatched, this leads to cracking, delamination, or stress concentration when the part cools. For example, metal inserts expand less than thermoplastics, so design tolerances or material choice (e.g., insert preheat, choosing plastics with a lower coefficient of expansion) help mitigate.

Surface Treatment & Insert Geometry to Improve Bond

Surface features like knurling, grooves, or rough finish on the insert increase mechanical interlock. Treatments such as plating, coating, or even texturing help improve adhesion. Inserts need adequate embedment depth, well-designed bosses/spacers to support the insert, and proper surface cleanliness (free of oils, burrs) to avoid bonding failures.

Chemical & Environmental Resistance Requirements

Where products will be exposed to chemicals, UV, moisture, or temperature cycling, material choice must factor in not just initial bond, but long-term durability. For example, stainless steel or certain plated metals paired with resins like PEEK or high-performance engineering thermoplastics can cope better with harsh environments. Similarly, plastic or resin inserts may be used in non-load or non-structural areas where corrosion or conductivity is not critical.

Choose Durable and Cost-Effective Materials

Sometimes a more expensive insert (metal, treated, complex geometry) increases upfront cost but saves money over life (less failure, less rework). Engineers should evaluate total cost of ownership: material cost, tooling cost, processing time, defect rates, maintenance. Under-engineering the insert or resin to save cost can backfire.

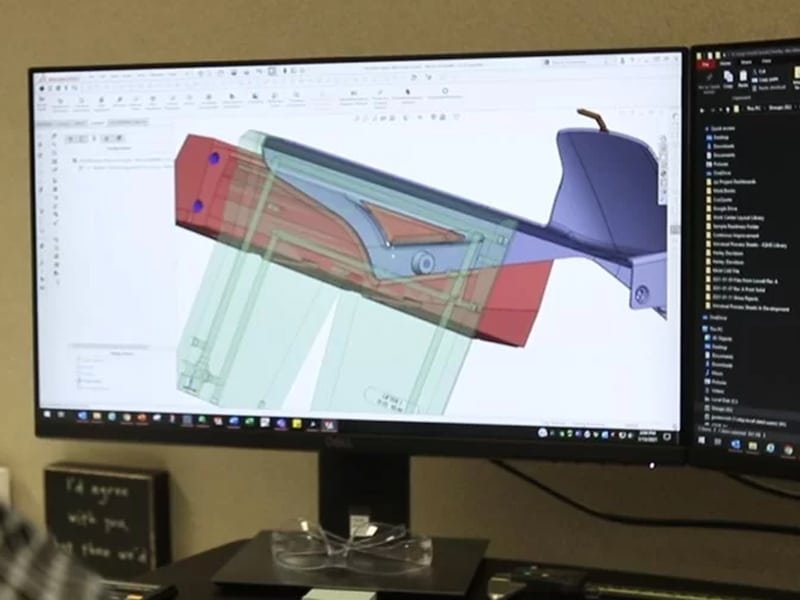

Insert Molding Design Guide Considerations

The manufacturability of insert molded parts is influenced by the design of both the insert and the mold. A well-designed part ensures that the insert is placed securely and correctly in the mold cavity while also allowing the molten plastic to flow around it efficiently. Design for manufacturability (DFM) principles should be applied to ensure ease of assembly, material flow, and insert placement, ultimately reducing production time and costs.

Simplifying the design by minimizing complex geometries can also aid in achieving cost-effective and reliable insert molding. Here are some effective design considerations.

Choose Proper Insert Fit & Lock-Features

Ensure the insert has either precise clearance or a press fit based on resin shrinkage. Use knurls, grooves, or undercuts on the insert surface to mechanically lock it in place. But avoid overly aggressive knurls that obstruct flow or cause stress concentrators. For axial loads, embed the insert deep enough—often at least twice the insert’s diameter—to distribute force properly.

Wall Thickness Uniformity Around Inserts

Maintain consistent wall thickness around the insert to avoid uneven cooling, warpage, or sink marks. Transition gently in cross-section near the insert to avoid sharp changes. Typical wall thickness for many thermoplastics is 1.5-3.5 mm. Thin walls may lead to incomplete fill; thick ones increase cycle time and risk voids.

Suitable Draft Angles & Parting Line Placement

Provide a suitable draft (1°-2° or more if surface texture demands) on vertical faces, especially where plastic engages inserts. Avoid locating parting lines through an insert or at a high-stress interface, which can weaken the insert region or cause flash buildup. Proper draft and parting line reduce ejection force and mold damage.

Insert Positioning Relative to Edges & Support Structure

Do not place the insert too close to part edges or thin sections. Maintain at least ~2× wall thickness from insert to nearest edge to prevent cracking during ejection or under load. Ensure there is plastic backing/support beneath the insert so that the load is transferred into the surrounding material, not just the insert.

Threaded Insert Embedding & Orientation

For threaded or functional inserts, ensure the insert is rigidly supported and aligned during molding. Use preheat or tooling fixtures if needed to compensate for thermal mismatch. Also expect sink marks beneath large inserts; avoid showing surfaces under load unless fully supported.

Tolerance Design & Shrinkage Compensation

Define tolerances both for inserts and the molding features that interact with them. Account for resin shrinkage and thermal expansion mismatch during cooling. For instance, the plastic shrink beneath a metal insert may pull on the insert; design for enough plastic thickness or use resins with good elongation to absorb stress.

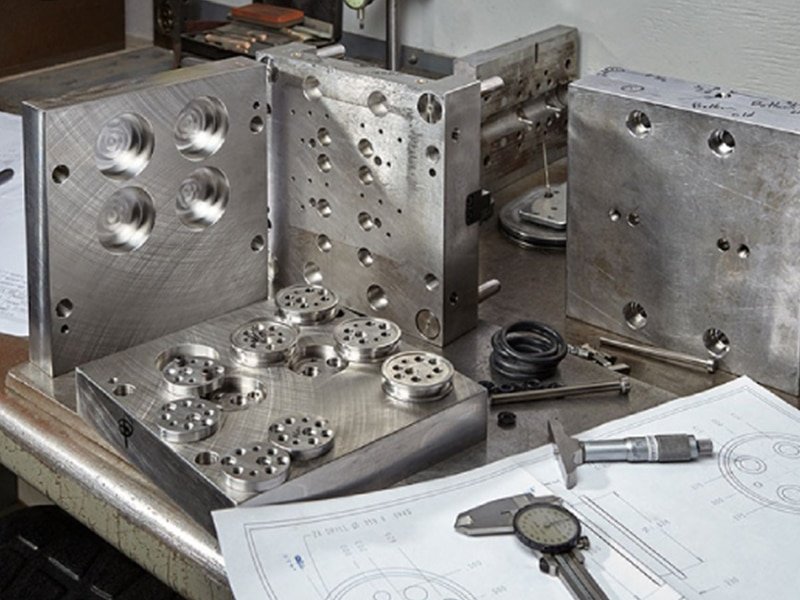

Tooling and Mold Design for Insert Molding

A mold is the foundation of reliable insert molded parts. Mistakes in mold design translate into scrap, defects, or shorter tool life. Here are some useful design considerations.

Choose a Suitable Mold Material and Careful Treatment

Select mold steel grades that match expected wear and temperature cycles. For example, use P20 or 718 steels for moderate runs; hardened steels like H13 or S7 if bulk plastics with fillers or metal inserts are used. Ensure inserts themselves are hardened or plated if they will face abrasion or repeated torque. Heat treatment of mold cavities near the insert seat should minimize distortion over time; hardness targets in those zones are often 48-52 HRC.

Design Cooling Channels Around Insert Zones

Because metal inserts conduct heat differently from surrounding plastic, mold halves must be designed with cooling channels near insert areas. Using copper inserts or beryllium copper cores for sections around heavy inserts can improve cooling. Maintain mold temperature differential < 5 °C across the tool near insert pockets to reduce residual stress or warpage. Consider conformal cooling if the cavity geometry is complex.

Gate, Vent, Ejector Layout Near Inserts

Design the gate location so plastic flows toward the insert without creating knit lines that cross the insert faces. Provide vents close to the insert edges to let trapped air escape. Ejector pins should be placed away from inserts or set up so force is evenly distributed—pins should avoid being directly under tight-tolerance insert geometries that would distort or damage them. For example, when the insert is near the mold surface, use multiple ejectors or split ejector plates to prevent peeling.

Tolerance & Finish for Insert Seating

Tooling surfaces in contact with insert edges or flanges need a tighter finish (e.g., Ra ≤ 1.6 µm or as required) to prevent flash or parting line blemishes. Machined features holding inserts must respect tolerance stack-ups: insert height vs cavity closure, location versus mold shrinkage. Tools should allow periodic maintenance: easy access to replace insert pockets, polish insert seating surfaces, and inspect ejector alignment. For a longer lifetime, coat high-wear regions (e.g., insert pockets) with wear-resistant coatings (nitriding or PVD) if applicable.

Optimize Insert Molding Process

Process optimization bridges design and production. Efficient process tuning ensures parts are made quickly, with fewer defects, and with better repeatability. The following are key technical improvements in process optimization.

Balance Cycle Time and Holding Pressure

Instead of pushing for fastest filling, calibrate the hold-pressure sequence. After fill, pause to let inserts stabilize, then apply holding pressure long enough to avoid sink marks but not so long as to overheat surrounding plastic. Monitor part weight vs. shrinkage during cooling to find optimal hold time.

Preheat Inserts for Thermal Stability

Preheat inserts close to mold cavity temperature to reduce thermal shock. A cold insert in a hot mold can cause local over-cooling, uneven flow, or stress concentration. Ensuring thermal equilibrium improves bonding and reduces cycling variation.

Use Automated or Fixture-Based Insert Placement

Where possible, use fixtures, robotic pick-and-place, or custom insert holders in mold to reduce misplacement, especially for high volume runs. Manual loading increases variability; consistent orientation and seating ensure better encapsulation and fewer defects.

Monitor Process Data to Reduce Defects

Record key parameters: melt temperature, injection pressure, cooling time, part weight, dimensional variation. Use small sample runs to test these variables. For example, track part weight to detect flash or short shots. Adjust gate size or injection speed based on these data. Continuous feedback improves yields.

Advantages of Insert Molding

Cost-Effectiveness for Complex Parts

Increased Part Strength and Durability

Design Flexibility and Customization Potential

Reduced Assembly Time and Costs

Challenges in Insert Molding

Insert Positioning and Alignment Challenges

Bonding Issues Between Insert and Molding Material

Dealing with High Tolerances in Insert Molding

Managing Cycle Time and Production Costs

Quality Control in Insert Molding

Ensuring Consistent Insert Placement and Bonding

Quality control in insert molding is crucial to ensuring that inserts are properly placed within the mold and securely bonded with the surrounding material. The placement of the insert must be precise, as even slight misalignments can compromise the integrity of the part. Automated systems are often employed to verify insert placement, and molds are designed with features that securely hold the insert in position during the injection process. Furthermore, the bonding between the insert and the molding material must be consistent and reliable to ensure the part functions as intended. Monitoring and adjusting mold temperatures, pressures, and material flows are key practices for ensuring robust bonding.Monitoring Material Flow for Optimal Insert Molding Results

Material flow plays a significant role in achieving optimal results in insert molding. During the injection phase, the plastic material must flow around the insert smoothly and evenly to ensure a secure encapsulation. Inconsistent flow or poor material distribution can lead to weak spots, incomplete bonding, or uneven part quality. Engineers typically monitor material flow using advanced tools, such as pressure sensors and thermocouples, to ensure the correct injection speed and pressure are applied. Adjustments to these parameters can help maintain uniformity in the molded part, ensuring consistent quality and reliability across production runs.

Common Defects in Insert Molding and How to Prevent Them

Insert molding is prone to certain defects that can impact part quality and performance. Common molding defects include incomplete insert encapsulation, misalignment of the insert, air traps, or inadequate bonding between the insert and the molding material. To prevent these defects, manufacturers must carefully control mold design, insert placement, and material flow. Ensuring the right temperature and pressure settings during the injection process can also mitigate defects like warping or flash. Preventative measures, such as routine mold maintenance, proper material selection, and regular process monitoring, are essential for reducing the likelihood of defects.Inspection Methods: Visual, Dimensional, and Functional Testing

To ensure the highest quality standards, insert molded parts must undergo thorough inspection processes. Visual inspection is used to identify surface imperfections such as cracks, voids, or flash, which can affect the aesthetic and functional quality of the part. Dimensional inspection involves measuring key dimensions of the molded part to ensure they align with the specified tolerances. This is often done using precise measuring instruments like calipers, micrometers, or coordinate measuring machines (CMM). Functional testing evaluates the performance of the part under real-world conditions, ensuring that the insert and molded material bond securely and that the final part meets all mechanical and operational requirements.Insert Molding vs. Traditional Molding Techniques

Insert Molding vs. Injection Molding

Insert molding shares many similarities with traditional injection molding but incorporates the use of pre-placed inserts into the process. While injection molding typically involves only molten plastic being injected into a mold to create a part, insert molding involves the additional step of placing an insert into the mold before the injection. This allows for the creation of parts that benefit from the strength and functionality of both the insert material and the plastic material. The main advantage of insert molding is its ability to integrate complex components, such as metal threads or electrical connectors, into a molded plastic part in a single operation. In contrast, injection molding typically requires separate assembly processes for such components. View our Precision Injection Molding ServiceInsert Molding vs. Overmolding

Insert molding and overmolding are both processes that involve adding a secondary material to an existing part, but they differ in their approach and application. In overmolding, a layer of material is applied over a substrate, typically using the same molding material to improve features like grip or protection. In contrast, insert molding involves embedding a separate, pre-formed insert (often made from a different material, such as metal or ceramic) into the molded part. Overmolding is often used for adding a soft outer layer, like rubber over a plastic base, whereas insert molding is ideal for incorporating functional components, like threaded metal inserts, into a plastic part for strength and durability. View our Overmolding ServiceAdvantages and Disadvantages of Insert Molding Over Other Methods

Insert molding offers several advantages over traditional molding techniques. It enables the integration of stronger and more functional materials, such as metal or ceramic inserts, into plastic parts. This reduces the need for additional assembly steps, making the process more efficient and cost-effective. Insert molding also enhances the performance and durability of the final product by providing reinforced or specialized features like electrical conductivity, mechanical threads, or heat resistance. However, insert molding can be more complex and requires precise tooling to ensure proper insert placement and bonding. Additionally, the process may be more expensive than simple injection molding due to the need for specialized inserts and tooling.Applications of Insert Molding Across Industries

Automotive Industry: Structural Components and Fasteners

In the automotive industry, insert molding is used extensively for creating parts that require both strength and precision, such as structural components and fasteners. Metal inserts, such as steel or aluminum, are often used to reinforce plastic parts that will bear heavy loads or experience stress during operation. Common automotive applications include brackets, connectors, and fasteners that require precise alignment and robust bonding to ensure safety and durability. Insert molding also offers the benefit of reducing the need for additional assembly steps, streamlining production and improving overall efficiency.Medical Device Manufacturing: Ensuring Precision and Functionality

In medical device manufacturing, insert molding is used to create highly precise and functional parts that meet stringent regulatory standards. For example, metal inserts are often embedded in plastic housings to create secure connections for medical instruments or implants. This allows for the creation of parts with high strength and low weight while also ensuring easy integration of components such as screws, connectors, or electrical circuits. The use of insert molding in medical devices ensures that critical parts, like those used in surgical instruments or diagnostics equipment, are reliable, sterile, and long-lasting.Electronics: Use of Insert Molding for Connectors and Housing

Consumer Goods: Durability and Aesthetic Applications

Insert molding is also used in the production of durable consumer goods, where aesthetics and functionality must be combined. For example, metal inserts can be used in plastic housings for tools, appliances, or toys, providing structural strength while maintaining a lightweight and visually appealing design. This method enables the production of durable products that are also easy to use and handle. Insert molding can also improve the tactile properties of consumer goods by incorporating soft-touch or ergonomic features, enhancing the user experience.Industrial Applications: Heavy-Duty Parts and Assemblies

Industrial applications often require parts that can withstand heavy-duty use and extreme conditions. Insert molding is ideal for producing components like heavy-duty gears, connectors, and structural supports that require both strength and resilience. Metal and ceramic inserts are commonly used in industrial applications to provide reinforcement and improve the wear resistance of plastic parts. Insert molding allows for the creation of these high-performance components in a cost-effective manner, with reduced assembly time and fewer potential points of failure.Choosing the Right Insert Molding Service Provider

Key Criteria for Selecting an Insert Molding Manufacturer

Choosing the right insert molding manufacturer is crucial for ensuring the success of the project. Key factors to consider include the manufacturer’s experience with insert molding, the range of materials they work with, and their ability to meet project timelines. Additionally, it’s important to assess their capacity for high-precision molding, as insert molding often requires exact tolerances and attention to detail. Working with a manufacturer that has a proven track record in the industry ensures that the final product will meet both functional and quality standards.Assessing Technical Capabilities and Experience

When selecting an insert molding service provider, it’s essential to assess their technical capabilities and experience. A skilled manufacturer will have the knowledge to select the right materials, design the mold, and manage the intricacies of the insert molding process. Experience with various insert types and complex geometries is also important to ensure the manufacturer can meet your project’s specific requirements. Choosing a provider with extensive technical expertise reduces the risk of defects and ensures high-quality production.Understanding Lead Times, Costs, and Production Schedules

Lead times, costs, and production schedules are key considerations when choosing an insert molding partner. It’s important to align your production timelines with the manufacturer’s capabilities, ensuring they can meet deadlines without compromising quality. Understanding cost structures, including tooling and material costs, is essential for budgeting and assessing the overall value of the project. A reliable service provider should offer transparent pricing and realistic production schedules, helping you plan and manage your project effectively.How to Collaborate with Your Insert Molding Partner for Best Results

Effective collaboration with your insert custom molding partner is essential for achieving the best results. Clear communication regarding design specifications, material selection, and production expectations ensures that both parties are aligned throughout the project. Regular updates and feedback during the design and prototyping phases help prevent misunderstandings and improve the final product. By working closely with your manufacturer, you can address potential issues early, optimize the process, and ensure that the final product meets all performance and quality requirements.Submit Your Insert Molding Request

Insert molding is a highly versatile and efficient manufacturing process that integrates the benefits of both molding and insert placement to produce strong, durable, and functional parts. By carefully selecting materials, optimizing design considerations, and working with experienced manufacturers, companies can leverage insert molding to produce high-quality components across various industries. Whether for automotive, medical devices, electronics, or industrial applications, insert molding offers a powerful solution for creating complex, reliable parts with minimal assembly and enhanced performance.