POM Injection Molding Service

Erye Offer POM Injection Molding Service to Specific to Your Needs!

POM (Polyoxymethylene), also known as acetal, is valued for its high stiffness, low friction, and excellent dimensional stability, making it ideal for precision parts in demanding applications. Our injection molding expertise ensures that POM components achieve superior mechanical performance, tight tolerances, and a flawless finish.

Our POM injection molding capabilities includes,- Free & fast DFM report with optimized designs

- In-housing tooling for fast turnaround with high precision

- Reinforced POM molding with additives like glass fiber for enhanced strength

- High-precision molding for complex geometries and tight tolerances

- Custom surface finishing to enhance POM parts performance

- Secondary processing including machining, ultrasonic welding, and assembly

POM Delrin Injection Molding Services

| Service | Details |

|---|---|

| Maximum Part Size | 2500mm x 2000mm (98 in. x 78 in.) |

| Recommended Wall Thickness | 0.89 mm and 3.81 mm(0.035 to 0.150 inches) |

| Color Options | Any color according to RAL or Pantone Code |

| Standard Finishes | SPI and VDI |

| Mold Ownership | Customer owned with mold maintenance |

| Mold Life | Unlimited (If the POM mold worn out, Erye will cover the cost of new mold) |

POM Delrin Injection Molding Design Guidelines

| Item | Description |

|---|---|

| Wall Thickness | Maintain uniform wall thickness between 0.8mm and 3.0mm to reduce differential shrinkage and warpage. Avoid abrupt thickness transitions. |

| Draft Angles | Ensure 0.5°–2° draft to facilitate part ejection without surface defects, especially for textured surfaces. |

| Fillets and radii | Use a minimum radius of 0.5mm at internal corners to prevent stress concentration and potential cracking. |

| Rib design | Ribs should be 40–60% of the adjacent wall thickness to prevent sink marks while adding strength. |

| Venting | Provide adequate venting (vent depth 0.02–0.05mm) to prevent gas entrapment, which can cause burn marks or short shots. |

| Shrinkage allowance | Consider POM’s shrinkage (1.8%–2.5%) when designing mating parts, particularly for press-fit or snap-fit applications. |

| Bosses and fasteners | Design bosses with an outer diameter 2–3 times the screw diameter and reinforce with gussets to avoid cracking under load. |

| Snap-fit design | For snap-fit features, maintain a deflection strain below 5% to prevent permanent deformation or fracture. |

| Tolerance control | Due to POM’s thermal expansion, set realistic tolerances (±0.05mm–±0.10mm) based on the part size and function. |

Start Delrin Plastic Molding Project

Advantages of POM Injection

Exceptional Dimensional Stability

High Stiffness & Strength

Low Friction & Excellent Wear Resistance

Superior Fatigue & Creep Resistance

Good Impact Strength

Disadvantages of POM Injection

Poor UV Resistance

Difficult to Bond or Paint

Expands with Heat

Risk of Breakdown During Processing

POM Injection Molding Product Applications

Automotive

- Gear mechanisms

- Fuel system components

- Door locks and latches

- Steering column bearings

Electronics & Electrical

- Connectors and switch housings

- Insulating components

- Cable ties and wire management clips

- Printer and scanner gears

Medical Device

- Inhaler components

- Surgical instrument handles

- Drug delivery system parts

- Prosthetic joint components

Industrial Components

- Precision gears and pulleys

- Conveyor system rollers

- Bearings and bushings

- Fasteners and clips

Additonal Options for POM Parts

Case Study of Automotive Glove Box Development

Related Delrin Injection Molding Resources

Plastics have become a primary material in modern vehicle manufacturing. The use of automotive plastic

On-demand manufacturing offers a flexible and efficient alternative to traditional manufacturing models. This innovative approach

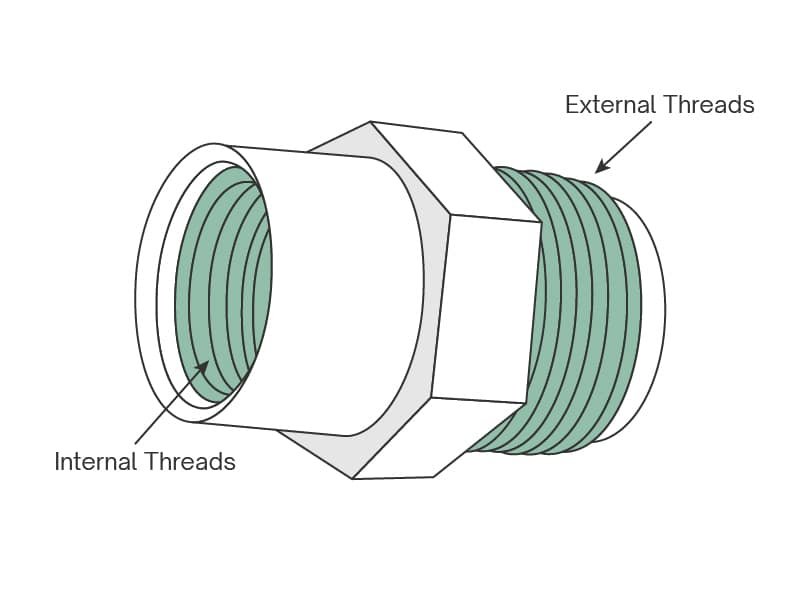

Molded threads are all around us—from soda bottle caps to the nuts under a kitchen