Precision China CNC Turning Service

As an China machining factory, we can provide high precision CNC turning service worldwide.

Erye has more than 20 sets of CNC lathes and turning centers. We can offer cost-effective CNC turning service with high precision.

The common application for CNC turning parts are:- Functional prototypes and end-use parts

- Parts with cylindrical features

- Parts with axial and radial holes, flats, grooves, and slots

The CNC Turning Services Basics

What is CNC Turning?

How Does CNC Turning Work?

Types of CNC Turning Process

| Type | Description |

|---|---|

| Taper Turning | This process gradually reduces the diameter of the workpiece to create a conical shape, commonly used for shafts and spindles. |

| Straight Turning | This involves producing cylindrical surfaces that are parallel to the axis of rotation, ideal for simple parts like axles and pins. |

| External Grooving | This technique creates grooves on the outer surface of a workpiece, allowing for precise depth and width control. |

| Profiling | Profiling cuts three-dimensional shapes into the surface of a workpiece, enabling the production of complex contours and slots. |

| Boring | This operation enlarges existing holes in a workpiece, enhancing their diameter and precision. |

| Drilling | Used to create holes in various materials, drilling can be performed on both external and internal surfaces. |

| Knurling | This process generates a textured pattern on the surface of a part, often used for grips or handles. |

| Threading | CNC turning can produce both internal and external threads, essential for fastening applications. |

| Hard Turning | This involves machining materials with high hardness levels (Rockwell C hardness > 45) as an alternative to grinding operations. |

| Facing | A process where the cutting tool moves perpendicular to the axis of rotation to create a flat surface at the end of a workpiece. |

CNC Turning Service Materials

CNC Turning Plastics

We provide precision turning service for variours plastics, ensuring lightweight and cost-effective solutions for different industries.

- ABS

- PC

- PA

- PP

- PMMA

- POM

- HDPE

- UHMWPE

- MC Nylon

- PTFE

- PS

- PVC

CNC Turning Metals

Our CNC turning capabilities cover a variety of metals, from lightweight aluminum to high-strength alloys, providing optimal solutions for different applications.

- Aluminum

- Stainless Steel

- Brass & Copper

- Carbon Steel & Alloy Steel

01

Send Drawings & Get a Quote

02

DFM & Mold Production

03

Sample Confirmation

04

Production & Quality Check

Advantages of CNC Turning with Us

High Precision and Accuracy

Quality Control and Consistency

Integrated Services

CNC Turning Services Applications

CNC Turning FAQs

Related Resources of CNC Turning

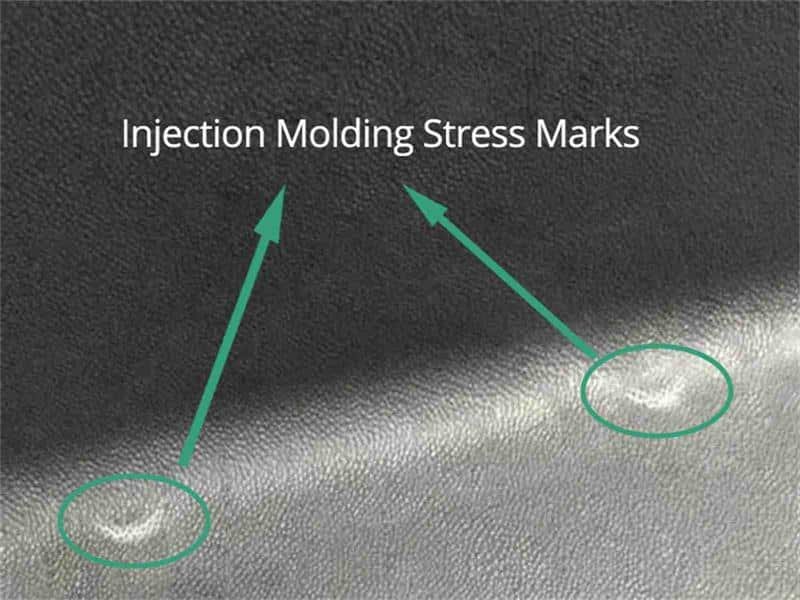

Shiny white marks on your molded parts signify internal stress. You must acknowledge that ignoring

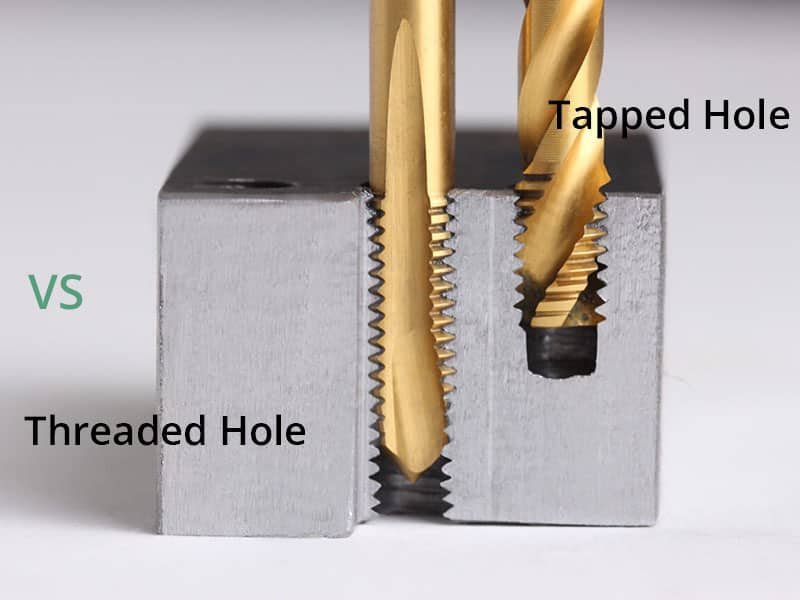

Tapped holes and threaded holes play crucial roles in joining plastic parts or plastics to

Jetting in injection molding creates worm-like defects when molten plastic shoots through the gate unchecked.