China CNC Milling Services

Get CNC milling parts with precision, reliable, and timely delivery that meet your manufacturing needs for both prototypes and high-volume production runs.

As a China CNC milling manufacturer, we provide high-precision custom CNC milling service worldwide.

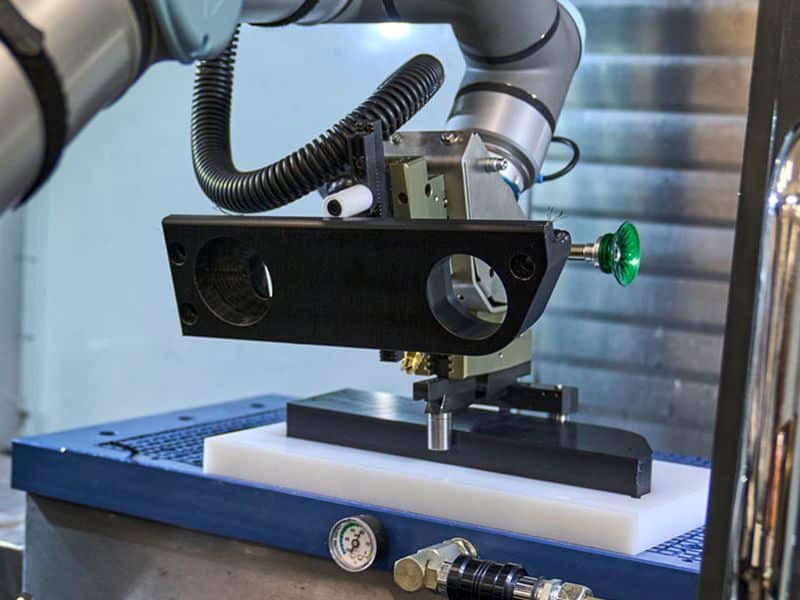

With more than 20 sets of CNC milling machines, including 3-axis, 4-axis, and 5-asix, we can produce complex geometris with tight tolerances. Our CNC milling machining service can work with various plastics and metals. The process ensures excellent surface finishes and efficient production for both prototypes and large-volume orders.

- Multi-Axis CNC Milling

- Custom Prototype Machining

- High-Volume Production

- Tight Tolerance Machining to ±0.005mm

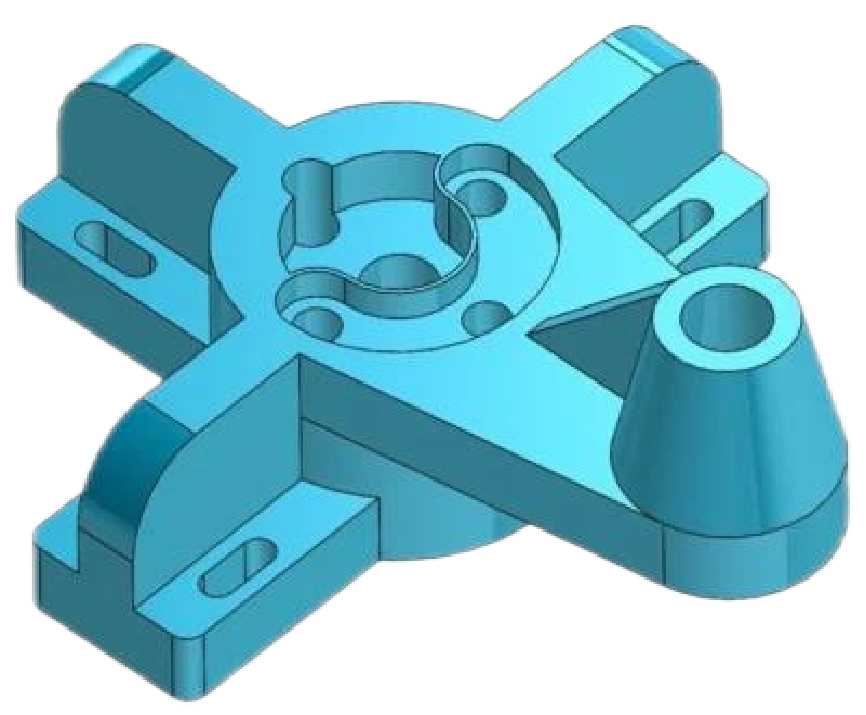

- Complex Geometries & Undercuts

The CNC Milling Services Basics

What is CNC Machining Milling?

CNC (Computer Numerical Control) machining milling is a precise and efficient manufacturing process that involves using computer-controlled machines to remove material from a workpiece, creating complex shapes and features.

How Does CNC Milling Work?

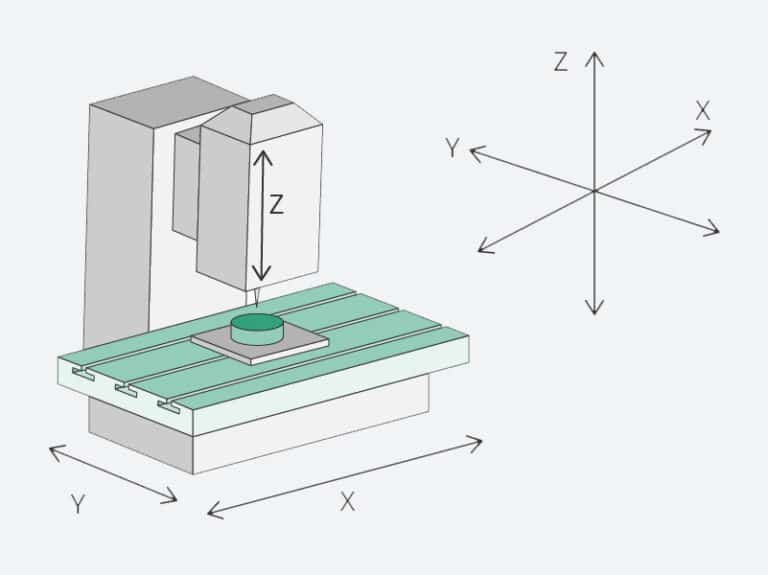

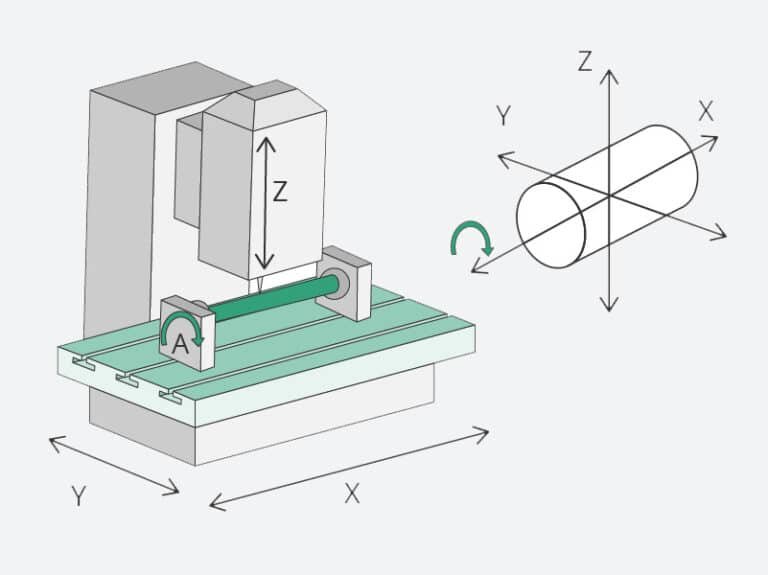

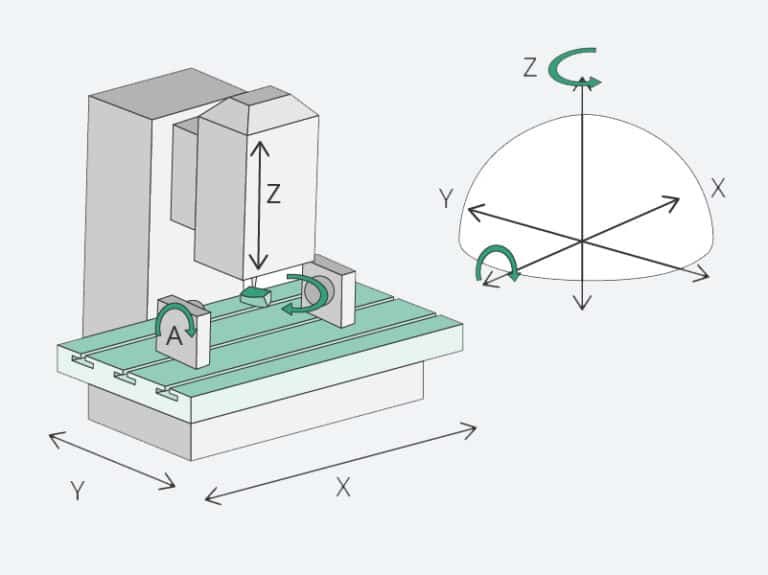

In CNC milling, a rotating cutting tool removes material from a stationary workpiece according to pre-programmed instructions (G-code). The machine moves along multiple axes (typically 3, 4, or 5) to cut, drill, or shape the material.

Our Custom CNC Milling Service Process

5-Axis Milling

A 5-axis milling machine allows the cutting tool to move along five different axes (X, Y, Z, and two rotational axes). This advanced machine provides the flexibility to produce highly complex and precise parts that require intricate geometries. It reduces the need for part repositioning and improves accuracy.

CNC Milling Services Materials

CNC Milling Plastics

We provide precision milling service for variours plastics, ensuring lightweight and cost-effective solutions for different industries.

- ABS

- PC

- PA

- PP

- PMMA

- POM

- HDPE

- UHMWPE

- MC Nylon

- PTFE

- PS

- PVC

CNC Milling Metals

Our CNC milling capabilities cover a variety of metals, from lightweight aluminum to high-strength alloys, providing optimal solutions for different applications.

- Aluminum

- Stainless Steel

- Brass & Copper

- Carbon Steel & Alloy Steel

01

Send Drawings & Get a Quote

Provide your 2D or 3D design drawings, we will evaluate and offer you a quote within 24 hours.

02

DFM & Mold Production

We'll conduct a Design for Manufacturing (DFM) review, then design and produce your molds.

03

Sample Confirmation

Review and approve samples until they meet your satisfaction.

04

Production & Quality Check

Once approved, we'll begin full production with thorough quality inspections.

Advantages of CNC Milling with Us

At Erye, we offer exceptional CNC milling services that stand out in the industry due to our advanced technology, precision, and expertise. You're selecting a partner with the skills, technology, and experience to deliver high-quality, precision-engineered parts that meet the most demanding requirements.

Precision and Accuracy

Our CNC milling machines are capable of achieving extremely tight tolerances, as low as 0.01mm, ensuring the highest level of precision for your parts. Whether it’s simple or complex designs, we guarantee that every piece will meet your exact specifications.

Advanced CNC Milling Technologies

With 3-axis, 4-axis, and 5-axis CNC machines, we can handle everything from basic to complex part geometries. Our state-of-the-art equipment ensures efficient production, minimal material waste, and optimal surface finish.

Skilled Engineering and Support

Our experienced team of engineers and machinists ensures that every aspect of your CNC milling project is handled with expertise. From design validation to final inspection, we provide comprehensive support throughout the manufacturing process.

CNC Milling Services Applications

CNC Milling Service FAQs

What materials can be used for CNC milling?

CNC milling can be performed on a wide variety of materials, including metals like aluminum, steel, and titanium, as well as plastics, composites.

What is the lead time for CNC milling?

Lead time for CNC milling depends on the complexity of the part and order volume. At Erye, our prototypes typically one week, while larger production runs can take longer to complete.

Can Erye use CNC milling to produce both prototypes and mass production parts?

Yes, CNC milling is highly versatile, making it suitable for both rapid prototyping and high-volume production, ensuring consistent quality across all parts.

What are the typical tolerances for CNC milling at Erye?

Generally, our CNC milling can achieve tolerances as tight as 0.01mm, depending on the machine and the material used. For more complex applications, tighter tolerances may be achievable.

How do I know if my design is suitable for CNC milling?

Our engineers will perform a Design for Manufacturability (DFM) review to ensure your design is suitable for CNC milling and can be efficiently produced with the required tolerances.

Do you offer CNC milling for small batch production?

Yes, we offer CNC milling services for both small batch and large-scale production, making it ideal for prototyping, short runs, and even mass production when necessary.

Related Resources of CNC Milling

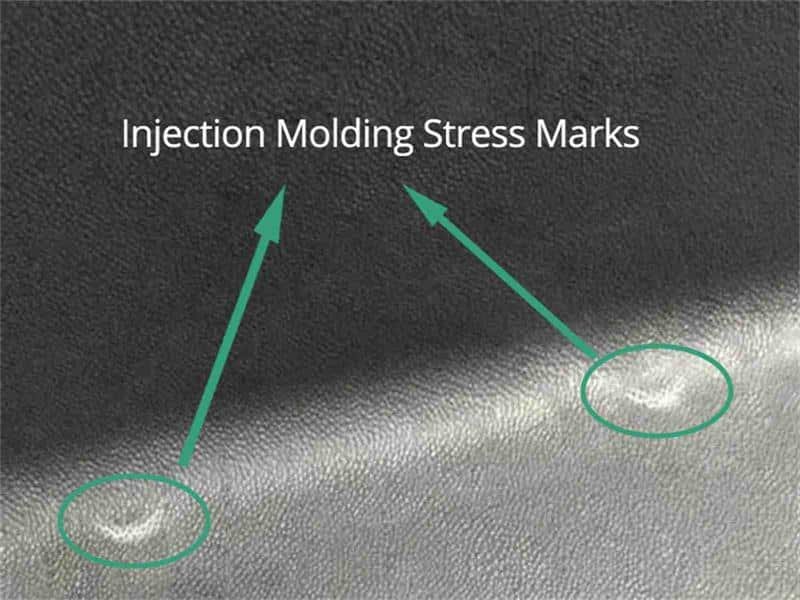

Shiny white marks on your molded parts signify internal stress. You must acknowledge that ignoring

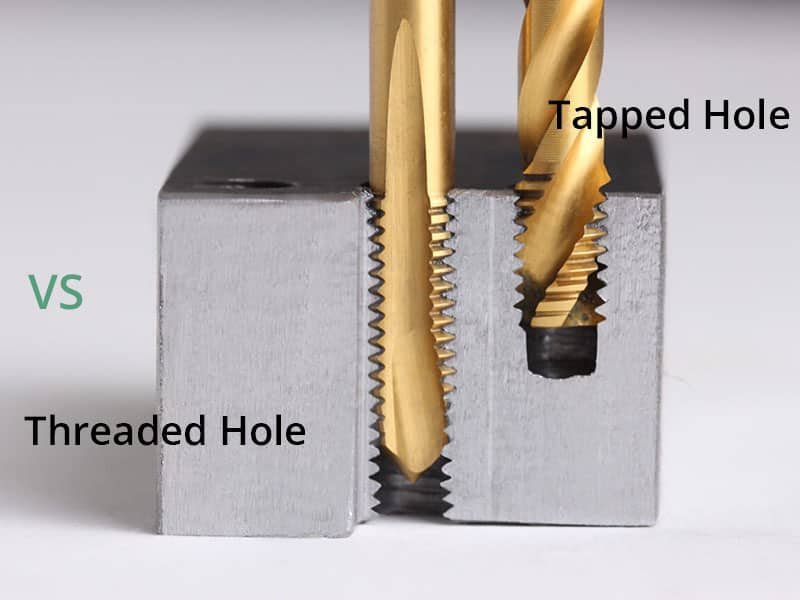

Tapped holes and threaded holes play crucial roles in joining plastic parts or plastics to

Jetting in injection molding creates worm-like defects when molten plastic shoots through the gate unchecked.