China CNC Machining Service

We are China CNC machining manufacturer, we offer custom machining parts worldwide.

CNC machining is an advanced manufacturing process that uses pre-programmed software to control precision and machinery. It is often used to create high-precision metal and plastic parts.

With years of experience and a workshop full of precision equipment, our team is able to handle both prototyping and full-scale production. We work with metals and plastics, and we know how to get your parts made right, on time, and aligned with your requirements.- Machined parts with tolerance down to ±0.02mm.

- Engineering support from start to finish.

- In-house custom jigs and fixtures for faster setup and better repeatability.

- Sendonary operations like surface finishing, light assembly, and part marking.

China CNC Machining Capabilities

EDM & Wire Cut Services

Materials for CNC Machining Service

ABS

PC

PA

PP

PMMA

POM

LDPE

HDPE

PVC

PTFE

PS

MC Nylon

UHMWPE

Aluminum

Stainless Steel

Carbon Steel

Copper

Brass

ABS

Acrylonitrile Butadiene Styrene

ABS (Acrylonitrile Butadiene Styrene) offers good impact resistance, durability, and excellent surface finish, making it suitable for a wide range of industries, including automotive, consumer electronices, and medical.

CNC machining with ABS ensures efficient production with minimal material waste, provide flexibility in design changes and high repeastability.

PC

Polycarbonate

PC (Polycarbonate) is a strong, transparent plastic known for its high impact resistance, optical clarity, and heat resistance, makes it widely used in applications that require durability and clarity.

PC CNC machining offers excellent dimensional stability and can be processed with tight tolerances, which allows it to be used for both structural and aesthetic.

PA

Polyamide

Polyamide (PA), or Nylon, is a popular material in CNC machining due to its excellent balance of strength, flexibility, and wear resistance. It is lightweight, has high mechanical strength, and offers good impact resistance.

PA CNC machining parts have good chemical resistance and the ability to withstand repeated stress.

PP

Polypropylene

Polypropylene (PP) is a lightweight, versatile material widely used in CNC machining for applications requiring durability, flexibility, and resistance to chemicals. It is ideal for applications in industries like automotive, medical, and consumer goods.

In CNC machining, PP is relatively easy to machine, offering good dimensional stability and a smooth finish.

PMMA

Polymethyl Methacrylate

PMMA, also known as acrylic, is a thermoplastic known for its excellent optical clarity, impact resistance, and UV stability.

PMMA CNC machining offers advantages such as high-dimensional accuracy and the ability to produce complex geometries with tight tolerances.

POM

Polyoxymethylene

POM (Polyoxymethylene), also know as acetal, is a high-performance engineering thermoplastic with exceptional mechanical properties. It is low friction, high stiffness, and excellent dimensional stability.

POM can be easily milled, turned, and drilled to create complex geometries and smooth finishes.

LDPE

Low-Density Polyethylene

LDPE (Low-Density Polyethylene) is a flexible and lightweight thermoplastic commonly used in applications that require high impact resistance, low friction, and chemical stability.

LDPE CNC machining is typically used to manufacture components like seals, gasekts, and custom parts that require flexibility and chemical resistance.

HDPE

High-Density Polyethylene

HDPE (High-density polyethylene) is a durable, strong, and stiff thermoplastic. With higher density compare to LDPE, HDPE has greater strength, rigidity, and resistance to wear.

HDPE has relatively low friction coefficient and ease of machining, HDPE CNC machining parts are widely used in construction, automotive, and water management.

PVC

Polyvinyl Chloride

PVC (Polyvinyl Chloride) is available in both rigid and flexible forms, and rigid PVC is more commonly used for CNC machining. It has excellent machinability, durability, and often used for applications requiring strength and stability.

In CNC machining, PVC can be precisely cut, drilled, and shaped to meet complex specifications with high dimensional stability.

PTFE

Polytetrafluoroethylene

PTFE (Polytetrafluoroethylene) has excellent chemical resistance, low friction, and high-temperature stability. It has unique non-stick properties and is able to resist harsh chemicals and extreme temperatures.

PTFE is relatively soft and expands easily when heated, so it is easy to machine. The PTFE Machining parts offer high precision with complex geometries.

PS

Polystyrene

PS (Polystyrene) is a lightweight, rigid thermoplastic. While it is not as durable as ABS or Polycarbonate, its excellent machinability allows it to be cut, drilled, and shaped into detailed parts.

Polystyrene CNC machining is typically used for applications such as electronics housings, displays, protective covers, and other low-stress applications that do not require high strength or impact resistance.

MC Nylon

MC Nylon

MC Nylon is a high-performance material for manufacturing durable, precision-engineered components. MC Nylon is particularly effective in applications that require parts to withstand heavy loads, impact, and abrasive conditions.

In CNC machining, MC Nylon is commonly used to create gears, bearings, bushings, and structural components that need to perform under demanding conditions. MC Nylon a preferred material for custom parts that require long-lasting durability and reliable performance.

UHMWPE

Ultra-High Molecular Weight Polyethylene

UHMWPE is a highly durable material with a high molecular weight. It provides outstanding impact resistance, wear resistance, and low friction, which makes it suitable for industries such as mining, food processing, and aerospace.

UHMWPE CNC machining is often used to produce precise parts with tight tolerances, it is ideal for manufacturing parts taht endure heavy wear and tear.

Aluminum

Aluminum

Aluminum is a lightweight, corrosion-resistant metal known for its excellent strength-to-weight ratio and versatility. It is widely used across various industries, including automotive, aerospace, construction, and packaging, due to its ease of fabrication, high durability, and thermal and electrical conductivity.

Aluminum also has good resistance to oxidation, making it ideal for both indoor and outdoor applications.

Stainless Steel

Stainless Steel

Stainless steel is a highly durable and corrosion-resistant alloy composed primarily of iron, carbon, and chromium. Known for its strength, versatility, and resistance to staining, rust, and oxidation, stainless steel is widely used in industries such as automotive, aerospace, food processing, medical devices, and construction.

It maintains its appearance and integrity even in harsh environments. Available in various grades, stainless steel can be tailored for specific needs.

Carbon Steel

Carbon Steel

Carbon steel is a strong and durable material made primarily of iron and carbon, with varying carbon content that influences its hardness, strength, and flexibility. It is widely used in construction, manufacturing, automotive, and machinery due to its affordability and ability to withstand high stress and impact.

Carbon steel is available in several grades, ranging from low-carbon steel (soft and malleable) to high-carbon steel (hard and brittle), making it suitable for a broad range of applications.

Copper

Copper

Copper is a highly conductive metal known for its excellent electrical and thermal conductivity, making it essential in electrical wiring, electronics, and heat exchangers. It is also valued for its corrosion resistance, malleability, and ductility, which allow it to be easily shaped and formed into various products.

Copper is widely used in plumbing, roofing, and industrial applications due to its durability and natural antimicrobial properties. Its ability to develop a protective patina over time adds to its aesthetic appeal and longevity, especially in outdoor and architectural uses.

Brass

Brass

Brass is an alloy primarily composed of copper and zinc, known for its strength, durability, and attractive gold-like appearance. It is highly malleable and resistant to corrosion, making it ideal for applications in plumbing, electrical components, musical instruments, and decorative items.

Brass also offers excellent machinability, making it easy to work with in manufacturing processes. Brass is commonly used in both functional and ornamental applications, providing a combination of aesthetics and performance.

China CNC Machining Solutions

Rapid Prototyping

If you are looking for the quick creation of prototypes, CNC rapid prototyping is one of the best methods. It is often used in the product development stage, producing prototypes for testing and validation before mass production at a relatively low cost and short time.

- Lead Time: 1~5 business days

- Capabilities: 1~100pcs

Low-volume CNC Machining

Low-volume CNC machining refers to produce small quantities of parts by CNC machining. At Erye, we can quickly adapt to changes without significant costs. Additionally, this method can minimize setup time and tooling expenses.

- Lead Time: 5~15 business days

- Capabilities: 100~1000pcs

End-use Production

CNC machining can also be used for high-volume production, the process allows continuous operation and minimal human intervention. Erye conducts rigorous quality control to ensure each part meets stringent specifications for CNC machining end-use production.

- Lead Time: 2~4 weeks

- Capabilities: Over 1000pcs

Advantages of CNC Machining with Us

High Precision

Fast Turnaround

Scalability

CNC Machining Applications

CNC Machining FAQs

Our standard tolerances are ±0.02mm, it may vary based on the overall size. Tighter tolerances are available for specific projects, we recommend that you mark the typical tolerance on the engineering drawing.

Yes, we specialize in low-volume prototyping and scalable high-volume production.

We provide CNC milling, turning, EDM, and wire-cut services.

Lead times typically range from 3 to 15 days, depending on the part complexity and volume.

Yes, we can. Erye can work with a wide range of metal and plastic materials for CNC machining. Please check our processing material page for details. If our general material cannot meet your requirements, we can machine parts with customer-supplied material. Contact our sales team and we can calculate the raw material weight for your machining part.

Yes, we review designs and provide DFM (Design for Manufacturing) feedback to optimize manufacturability.

Related Resources of CNC Machining

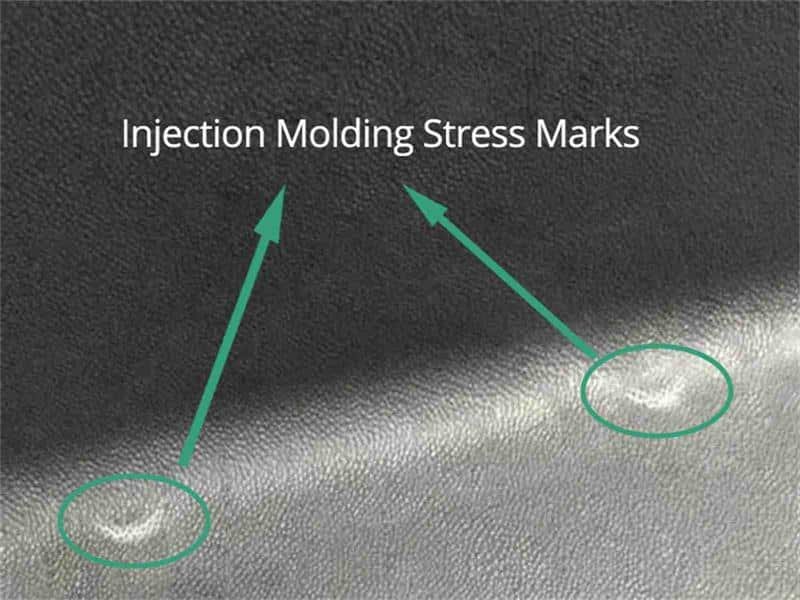

Shiny white marks on your molded parts signify internal stress. You must acknowledge that ignoring

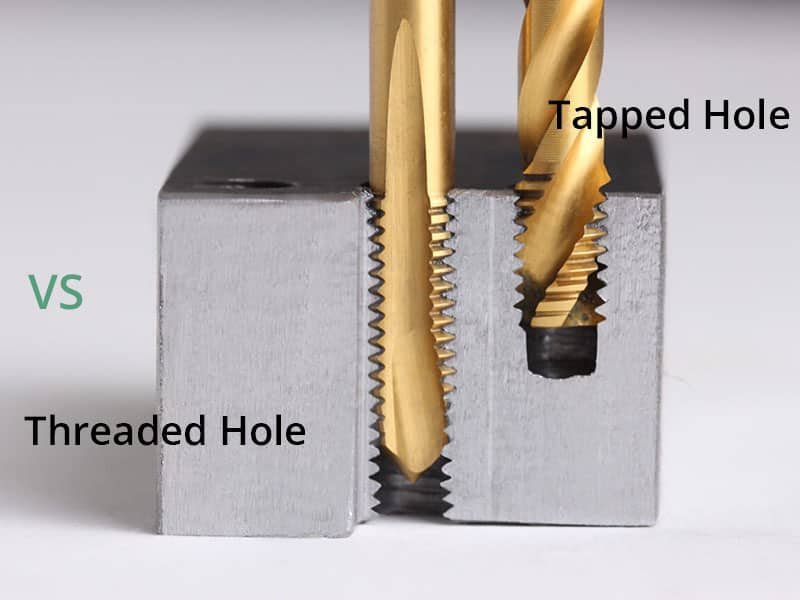

Tapped holes and threaded holes play crucial roles in joining plastic parts or plastics to

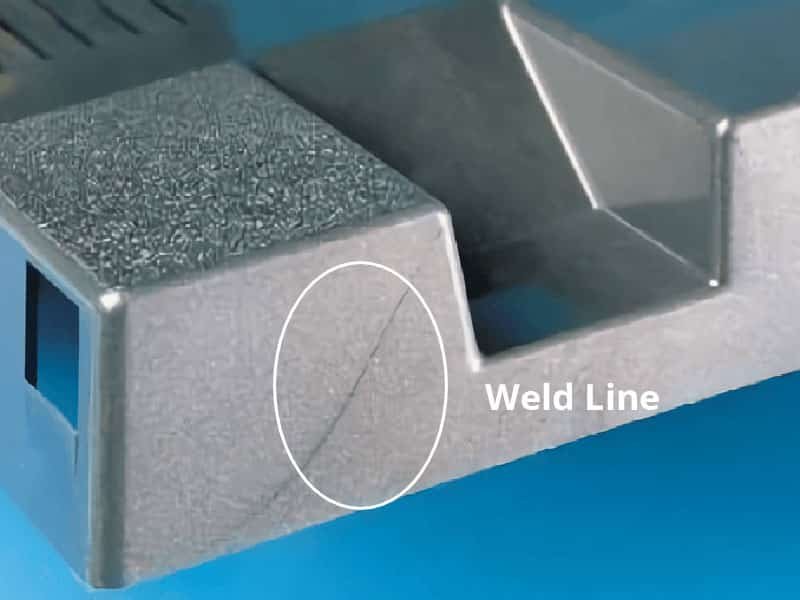

Jetting in injection molding creates worm-like defects when molten plastic shoots through the gate unchecked.

Living hinges design is among the most effective features in plastic design. They allow two

Off topic, but a fun fact: When you look at a plastic bottle cap under

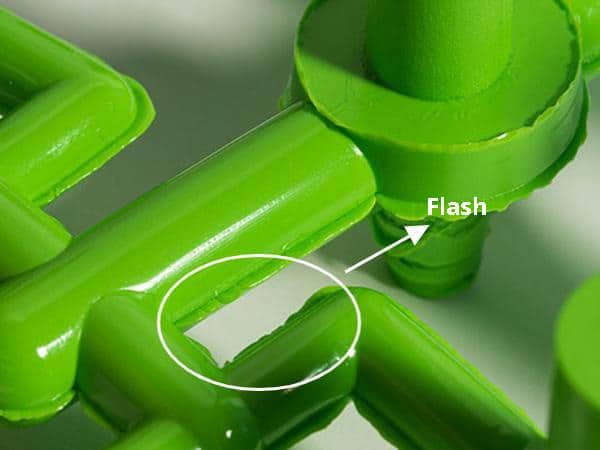

Flash in injection molding is one of the most common plastic molding defects. It significantly