Polymer materials are BY FAR the most unique materials in modern manufacturing. You see them everywhere from your smartphone case to car parts. In simple words, polymers are large molecules made up of repeating units. Two main types of polymer materials are: thermoset and thermoplastic materials.

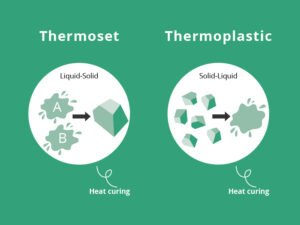

The main difference between thermoset and thermoplastic is the way they respond to heat. For example, thermoplastic materials can melt and reshape multiple times. On the other hand, Thermoset materials get hard permanently and this process occurs after initial heating. You cannot return them to their original form.

Understanding why materials are different is very important for engineers and designers. It helps them choose the right material for any project. Because it ensures that products work well, are affordable, and can be made easily.

Chemical Structure And Molecular Behavior of Thermoset and Thermoplastic

Thermoplastics

Thermoplastic molecular structure consists of long polymer chains. They are held together by weak forces. These chains can slide past each other when heated. The reason is that no permanent chemical bonds connect different chain segments.

Heat causes thermoplastic materials to soften and eventually melt. You know how butter melts when heated? Thermoplastics behave similarly. For instance, higher temperatures increase molecular movement and reduce material stiffness.

This process remains completely reversible. For example, the cooling process will return the material to its original solid state. In the same way, reheating will help reshaping multiple times without any chemical changes.

Thermosets

In Thermoset molecular structure, you will find extensive cross linking between polymer chains. These are permanent chemical bonds and they make a three dimensional network. Curing processes form these cross links through heat and chemical reactions.

When you heat it, thermoset materials first soften but then get hard permanently. Cross linking reactions occur during this heating phase. Notice things change dramatically once curing completes.

Subsequently, this process becomes irreversible. Additional heating cannot melt the material again. Instead, excessive heat causes decomposition and material degradation.

Thermoset and Thermoplastic Manufacturing And Processing Methods

Thermoplastic Processing

- Injection molding is the most common thermoplastic processing method. Heated plastic pellets melt and get injected into mold cavities. Next, cooling solidifies the material into your desired shapes.

- Extrusion creates continuous profiles like pipes and sheets. Molten thermoplastic gets forced through shaped dies. This method produces uniform cross-sections efficiently.

- Blow molding forms hollow containers and bottles. Air pressure inflates heated plastic against mold walls. Thermoforming shapes heated sheets using vacuum or pressure.

Thermoset Processing

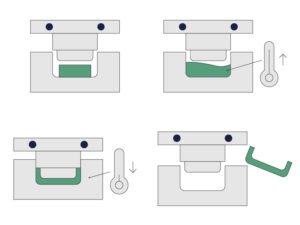

- Compression molding places uncured material into heated molds. Pressure and temperature trigger curing reactions. Transfer molding injects liquid resin into closed molds before curing begins.

- Resin transfer molding uses low-pressure injection of liquid resins. This technique works well for complex shapes and composite parts. Reaction injection molding mixes reactive components just before injection.

- Tooling requirements differ significantly between these processes. Thermoplastic molds need cooling systems. Thermoset molds require heating elements for proper curing.

Material Properties of Thermoset and Thermoplastic

Heat Resistance

Thermoplastic heat resistance varies widely among different types. Basic thermoplastics soften at relatively low temperatures. Engineering thermoplastics perform better at elevated temperatures but still have limits.

Thermoset heat resistance generally exceeds thermoplastic performance. Cross-linking provides excellent dimensional stability under heat. This point is important for high-temperature applications like aerospace components.

Structural Integrity And Hardness

Thermoplastic mechanical properties depend on molecular weight and structure. Higher molecular weights typically provide better tensile strength. Temperature significantly affects these properties.

You will find thermoset mechanical properties significantly consistent. And it happens across temperature ranges. Cross linking further creates rigid three dimensional networks. As a result, fatigue strength often surpasses thermoplastic alternatives.

Thermoplastic and Thermoset Recyclability

Thermoplastic recyclability comes with many advantages. These materials can melt and reshape into new products. Mechanical recycling processes work effectively with most thermoplastic types.

Thermoset recyclability also has some major challenges. For example, cross linked structures will resist melting and reshaping. Why? Because traditional recycling methods are ineffective. However, recyclable thermosets and chemical recycling show promise.

Environmental impact considerations favor thermoplastics in many cases. Plus, the circular economy benefits from recyclable materials. Eco scientists are doing more research to make bio based plastics.

Chemical And Creep Resistance

Thermoplastic chemical resistance varies significantly between different polymer types. Some resist specific chemicals well while others degrade quickly. Creep resistance becomes problematic under constant stress.

Thermoset chemical resistance typically surpasses thermoplastic performance. Cross-linking provides excellent protection against chemical processing equipment environments. Creep resistance remains superior due to rigid molecular structure.

Cost

Material costs favor thermoplastics in most applications. Raw materials cost less per pound generally. Particularly, recycled content reduces costs further.

Tooling and processing costs show mixed results. Thermoplastic injection molding requires expensive cooling systems but offers shorter cycle times. Thermoset molding needs heating equipment and longer curing periods.

Common Examples And Applications

Thermoplastic Examples And Uses

Polyethylene appears in packaging films and containers. Its flexibility and chemical resistance suit food packaging applications. Consumer electronics often use polyethylene components.

Polypropylene serves automotive components and textiles. Heat resistance makes it suitable for engine parts. Medical devices benefit from its sterilization compatibility.

Polyvinyl chloride creates pipes and vinyl siding. Chemical resistance suits construction applications. Electrical insulation properties make it valuable for wire coatings.

Polyethylene terephthalate forms bottles and fibers. Clarity and barrier properties suit beverage containers. Textile applications include clothing and carpets.

Thermoset Examples And Uses

Epoxy resins provide excellent adhesion and chemical resistance. Protective coatings use epoxy for corrosion protection. Aerospace applications require epoxy’s high strength-to-weight ratio.

Phenolic resins offer outstanding heat resistance and electrical insulation. Brake pads use phenolic compounds for their thermal properties. Electronic components benefit from electrical insulation characteristics.

Polyurethane creates flexible foams and rigid insulation. Automotive components use polyurethane for seat cushions. Construction applications include spray foam insulation.

Melamine formaldehyde produces hard, scratch-resistant surfaces. Dinnerware and laminates use melamine resins. Heat resistance makes it suitable for kitchen applications.

Conclusion

You want to select between thermosets and thermoplastics! It significantly depends on application requirements. Thermoplastics are very flexible in processing and can be recycled. Subsequently, thermosets give you better heat resistance.

Moreover, there are two manufacturing factors which are tooling and cycle times. Environmental and cost considerations are also important. Understanding these differences help engineers and designers to choose the right material for their products.

FAQs

Thermosets undergo a chemical change during curing and, once cured, cannot be remolten again. Thermoplastics can be melted and remolded multiple times without any change in their chemical composition. Cross linking installs permanent links in thermosets, while thermoplastics depend on physical bonds.

Thermosets typically have greater heat resistance compared to thermoplastics. The cross-linking imparts dimensional stability at high temperatures. If further heated to above their glass transition temperature, thermoplastics will soften and weaken.

Thermoplastics can be easily recycled by melting and reforming them into new materials. Cross-linked during the cure, conventional thermosets cannot be recyclable by the commonly used recovery process. But some new recyclable thermoset materials and chemical recycling approaches hold promise.

Generally, yes because thermosets are stronger than thermoplastics. Thermoplastics have rigid, and cross linked molecular structure. They maintain their strength and shape even when exposed to high temperatures

Thermosets are harder because of the cross-linking process. This process makes a three dimensional network of strong covalent bonds between polymer chains. Thermoplastics only have weaker intermolecular bonds.

In general, thermoplastics have a lower material cost and faster processing. The added expense of thermosets might be warranted by enhanced performance and durability when used in challenging applications.