Introduction to Vacuum Cleaner Molds

This case study involves developing an injection mold for a plastic vacuum cleaner housing. The housing is a core component of the complete vacuum, directly influencing the product’s appearance, structural strength, and user experience. The injection mold must meet large-scale production demands while ensuring flawless surface quality, precise dimensions, and compliance with strict durability testing standards.

As a China mold manufacturer, we design and manufacture the mold in-house. We can produce diverse housings and enclosures using various vacuum cleaner molds, either following customer designs or modifying directly from physical samples.

Requirements for Vacuum Cleaner Mold Production

- Mold design requires 2D drawing, 3D CAD files, or physical samples.

- In selecting mold steel, we follow customer requirements to choose the most suitable grade.

- As the housing is a visible, cosmetic component, customer demands no surface defects. Special care must be taken throughout mold design and manufacturing.

Mold & Tooling Material Selection

Injection molding processes vary widely, and the choice of mold steel affects the surface finish, precision, and the mold’s lifespan. Commonly used tooling steel include NAK80, S136, P20, 718, 45#, 40Cr, 2316, 2738 and others. Each grade has its own advantages and limitations. Our guiding principle is to select the most cost-effective material that meets quality requirements. For this project, we finally selected 718 mold steel, which enhances mold lifespan and housing surface glossiness.

Vacuum Cleaner Plastic Mold Design

A good mold structure is essential for quality manufacturing. We design the mold as follows:

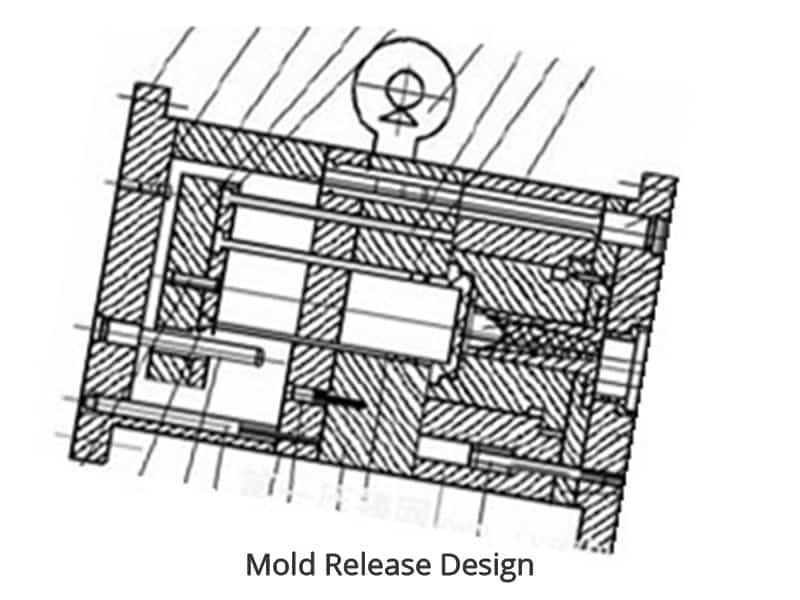

Mold Release Angle Design

The mold release draft angle depends on:

- Plastic performance

- Part geometry (e.g., height, depth, wall thickness)

- Mold cavity surface condition (roughness, texture)

Rigid plastics typically need larger angles than softer materials; complex geometries with many holes or thick walls require larger angles, while tall, deep parts need smaller angles to maintain dimensional control.

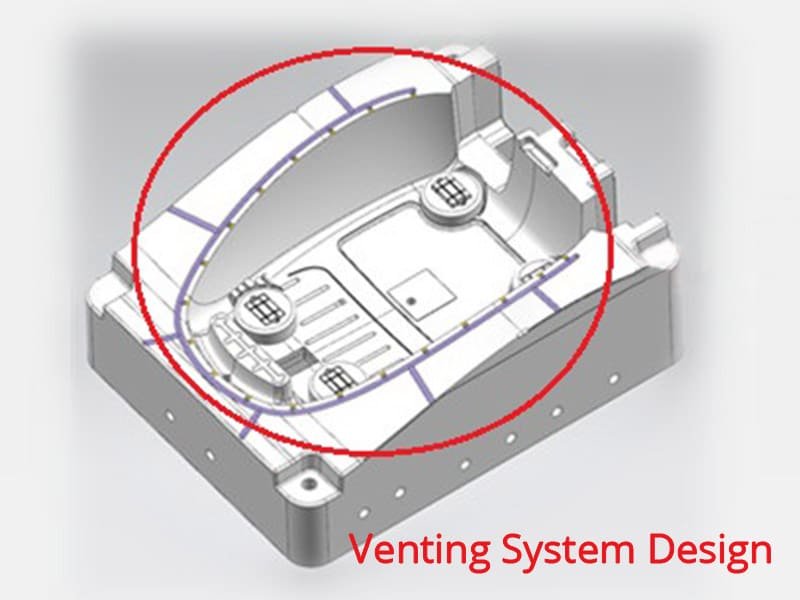

Venting System Design

The effective venting system is one of the most critical aspects of vacuum cleaner mold. We typically use vent grooves on the parting line. For top or bottom venting, we install inserts or vent pins to create a small gap-typically around 0.05mm (2 “threads”) to expel trapped air. Excessive clearance risks leakage or flash that could affect the appearance.

Cooling System Design

When designing a cooling system, we should balance cooling effectiveness and uniformity while considering structural impact. Key areas that require cooling include:

- The moving half of the mold and any inserts

- Side sliders and cores

- Standard cooling elements and specialized circuits

From the earliest design phase, our engineers analyzed each region’s cooling needs. We use circulating water throughout the mold to reduce cooling time, improving efficiency and reducing manufacturing costs.

Reducing Surface Sink Mark

The initial trial sample showed sink marks, which are unacceptable for appearance parts. To solve the problem, our engineers took the following solutions:

- Enlarged the gate area for better flow and to reduce holding pressure

- Optimized venting layout and positioned gates symmetrically for uniform fill

- Increasing cooling water flow

- Extending the injection and holding time to prevent early solidification

Vacuum Cleaner Mold Maintenance

After every batch of production, we maintain and store the mold, checking for a tight closure to prevent dust entry. Based on customers’ order cycles, we perform regular maintenance to ensure tooling lifespan and quality:

- Lubricate moving parts like ejector pins and guide pillars, clean vent grooves, and correct wear.

- Apply paint to the mold exterior and anti-rust oil to fixed/moving molds to prevent rust.

In this project, our engineers took full responsibility for every stage of vacuum cleaner housing production—from initial concept through to large-scale injection molding. The finished housings have consistently met stringent durability tests and earned positive feedback from our customers. Drawing on these proven processes, we combine in-house mold design, precision machining, and high-volume injection molding to deliver reliable, high-quality components.