The glove box, also known as the car glove compartment, is a storage unit typically located on the passenger side of the vehicle. It is used to store gloves and other small items. A typical automotive glove box consists of three to four plastic components, requiring three or four injection molds accordingly. The main components generally include the glove box lid, glove box switch, glove box housing, and glove box bin. Different vehicle models may have different configurations. As an exterior component, the glove box lid usually requires a textured (leather-like) surface finish.

At Erye, we specialize in the design and manufacturing of high-precision automotive molds and plastic injection components. The following case study showcases the complete process of developing a custom glove box mold for a well-known automotive brand, highlighting our expertise and capabilities as a professional glove box manufacturer.

Plastic Glove Box Structure Analysis

Below is the structure diagram of the plastic glove box. The material used is polypropylene (PP), with a shrinkage rate of 2% in the polypropylene injection molding process. The maximum external dimensions are 412.10 mm x 220.50 mm x 241.70 mm.

Key features of this plastic part include:

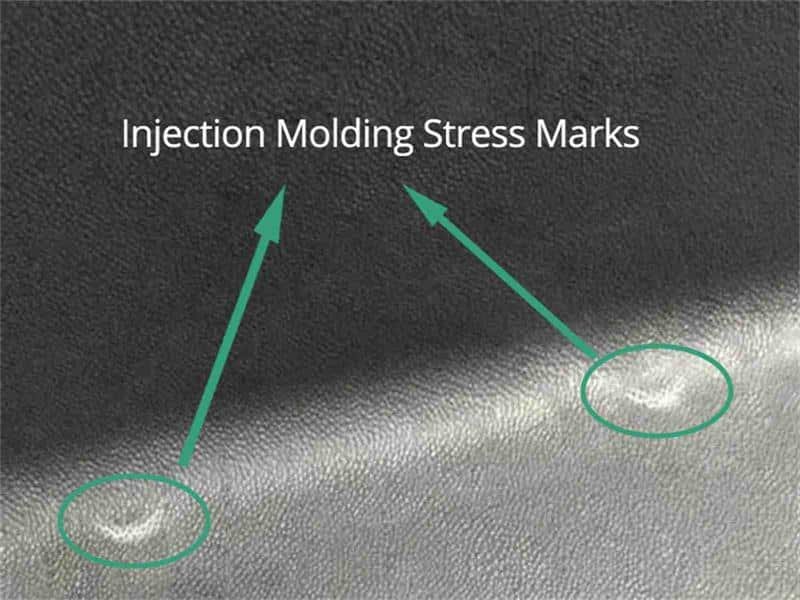

- The client has high requirements for appearance. The surface must be leather-grained with no visible defects. Putter marks, gate traces, shrink marks, weld lines, or flash are strictly prohibited.

- The part has a large and complex shape. Numerous reinforcing ribs were added to enhance rigidity and structural strength.

- There are three large undercuts on the inner side of the part. During lateral core pulling, the part is prone to deformation or even cracking, making each side of the core-pulling operation particularly challenging.

Injection Mold Design for Car Glovebox

After a detailed understanding of the client’s requirements and a thorough analysis of the car glovebox structure, our engineers proposed a customized mold solution. The mold adopts an inverted structure, with both the gating and ejection systems located on the fixed half of the mold. As the ejector system of the injection molding machine is not on the fixed side, we designed an oil cylinder system to push and reset the part from the fixed half.

Due to the increased length of the main runner in the inverted mold, a hot runner system was applied to ensure consistent material flow. The final mold dimensions were 970 mm x 850 mm x 850 mm, and the total weight was approximately 4000 kg, classifying it as a large-scale injection mold for glove box components.

Reliable Delivery and Stable Production Performance

Thanks to our years of industry experience and advanced in-house manufacturing capabilities, we completed the entire mold design and fabrication within 12 weeks. The mold was 100% independently designed and built by Erye. During the injection molding production phase, both the lateral core pulling and inverted demolding systems operated reliably and stably. The final car glove department part met all design and quality requirements. The final delivered automotive glove box demonstrated stable quality, and the client highly recognized our professional capabilities, leading to continued repeat orders and long-term cooperation.

Your Trusted Partner for Custom Glove Box Solutions

Whether you’re looking for a custom glove box or a complete car glovebox assembly solution, Erye is your reliable partner. As experienced glove box manufacturers, we offer one-stop services from mold design, manufacturing, to injection production, ensuring your project’s success with quality, precision, and efficiency.