The car central console is a crucial component located at the center of the vehicle cabin, used for controlling gear shifts, placing cups, and storing other items. Different vehicle models have different configurations of the center console, and even within the same model, the configuration may vary based on trim levels. As an exterior part, the surface of the automotive center console typically requires a leather-like texture finish.

This case study showcases how we designed and manufactured a custom mold for the center console vehicle of a well-known car brand.

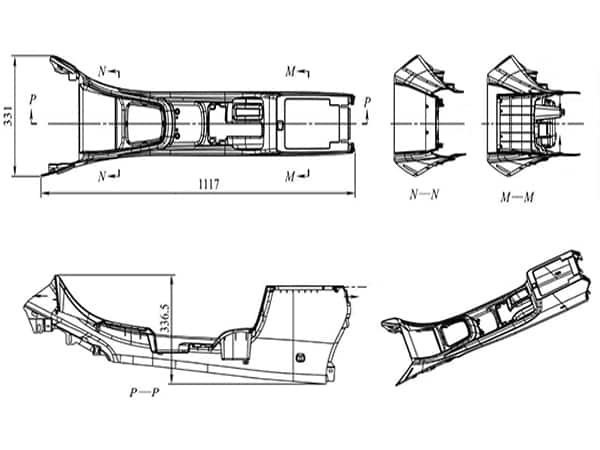

Plastic Part Structure Analysis

The structure diagram below illustrates the plastic automotive center console. The material used is PP-TD20, with PP being the base material for the outer cover of the console and TD20 indicating that 20% talc powder has been added to enhance the rigidity of the plastic part. The maximum dimensions of this plastic part are 1117 mm x 331 mm x 336.5 mm, making it a large thin-walled plastic part.

PP (Polypropylene) is a common material for injection molding, learn about our polypropylene injection molding service.

Key characteristics of this plastic part include:

- High appearance requirements. The surface needs to be leather-textured. Putter marks, gate traces, shrink marks, weld lines, or flash are strictly prohibited.

- The part is large, complex in shape, and features many reinforcing ribs.

- There are eight undercuts on both the inner and outer sides of the part, with large surface areas. These undercuts make lateral core pulling difficult and prone to deformation or cracking.

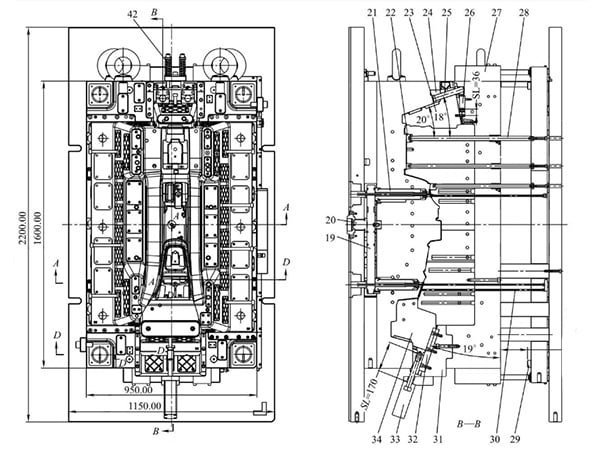

Car Central Console Injection Mold Design

Based on the structure characteristics of the center console vehicle plastic part, we adopted a hot runner sequence valve injection system. The final mold dimensions were designed to be 2200 mm x 1150 mm x 1185 mm, with a total weight of approximately 15 tons, making it a large injection mold. At Erye, we are capable of both in-house mold development and manufacturing, equipped with large machining centers and EDM machines. Additionally, we have large injection molding machines to produce large-sized plastic parts.

Our mold designers design from the following aspects:

- Molded part design

- Gating system design

- Lateral core-pulling structure design

- Temperature control system design

- Guide and positioning system design

- Demolding system design

Mold Performance and Results

After completing the mold design and manufacturing, we conducted a series of rigorous trials and optimizations to ensure reliable performance in actual production. The following highlights demonstrate how our engineering solutions effectively addressed the challenges of molding large, thin-walled automotive center consoles.

- The mold uses a two-point valve-gated hot runner system, which successfully addresses the filling issues for large, thin-walled plastic parts like the center console vehicle. The injection cycle and internal part quality both meet the design requirements.

- The mold uses a hydraulic oil cylinder as the ejection system, solving the challenges of high demold force and difficult reset operations.

- A secondary core-pulling structure ensures that core-pulling actions are stable, safe, and reliable.

The mold structure is advanced and rational, with precise dimensions. Since production began, the mold has operated safely, and the production process has been smooth. The molding cycle and part quality fully meet the client’s requirements.

Efficient Delivery and Client Satisfaction

This large-scale mold was completed in just 14 weeks, and we delivered satisfactory samples to the client. This achievement was made thanks to close collaboration between our engineers and the client. At Erye, we always adhere to the principle of delivering the best products in the shortest time, ensuring top-quality results with the fastest turnaround times.

As experienced custom automotive consoles manufacturers, we offer one-stop services from mold design, manufacturing, to injection production, ensuring your project’s success with quality, precision, and efficiency. If you need further assistance with custom automotive consoles or any large plastic molding projects, feel free to contact us.