Custom Vacuum Casting Service

As vacuum casting factory, we are able to provide custom vacuum casting service worldwide.

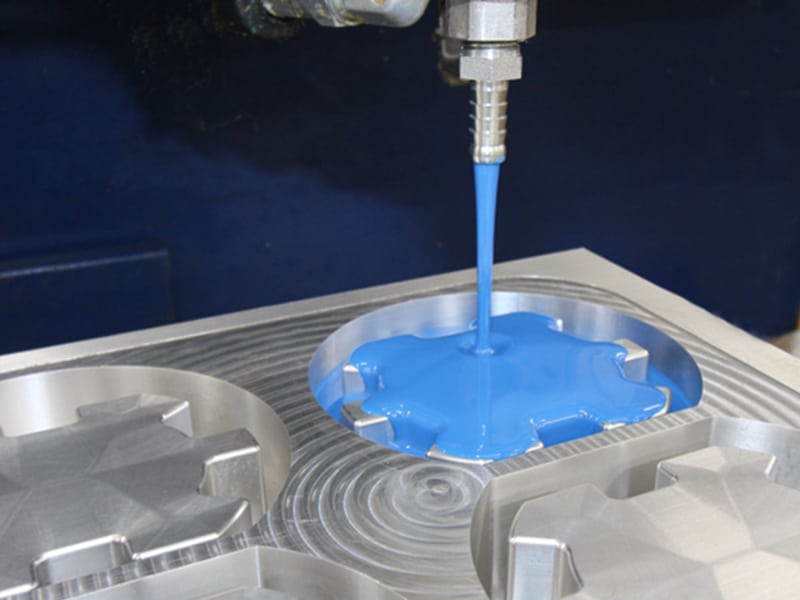

Vacuum casting is a process where liquid materials like urethane or nylon are poured into molds to create durable parts with specific properties. It’s an excellent choice for producing strong, wear-resistant parts that require intricate shapes, offering a reliable solution for industries from automotive to consumer goods.

Our vacuum casting services deliver parts with outstanding durability, flexibility, and resistance to impact and abrasion. Ideal for prototypes and production parts alike, vacuum casting supports projects that require consistent performance, even under demanding conditions.Vacuum Casting Service Specifications

| Service | Details |

|---|---|

| Process Materials | Urethane and nylon |

| Standard Finishes | SPI and VDI |

| Mold Service | DFM report and mold flow analysis |

| Mold Ownership | Customer owned with regular mold maintenance |

| Mold Cavities | Single or multi-cavities |

| Mold Life | Unlimited (If the mold worn out, Erye will cover the cost for the new set of mold) |

Vacuum Casting Service Capabilities

Urethane Cast Molding

MC Nylon Cast Molding

Additional Molding Options

Advantages of Vacuum Casting with Us

High Durability and Strength

Intricate Design Capabilities

Cost-Effective for Large Parts

Vacuum Casting Services Applications

Vacuum Casting Service FAQs

Yes, we design and produce all the mold in-house. Our China based mold & tooling workshop is equipped with advanced CNC machines and EDMs, ensure high precision mold making.

We can accommodate a wide range of sizes. From 3cm*3cm to 1500mm*1000mm. The size also differs from the overall structure.

Yes, we offer prototype samples for approval before moving to mass production.

Our tolerances comply with industry standards. Our generally tolerance is ±0.2mm, the tolerance is differ from product structure and size.

We require your design files, material preferences, and production volume to start. If you are uncertain for the material, you can also tell use using conditions, our material material can assist you. To start a project, please contact us and get started.

Related Resources of Vacuum Casting

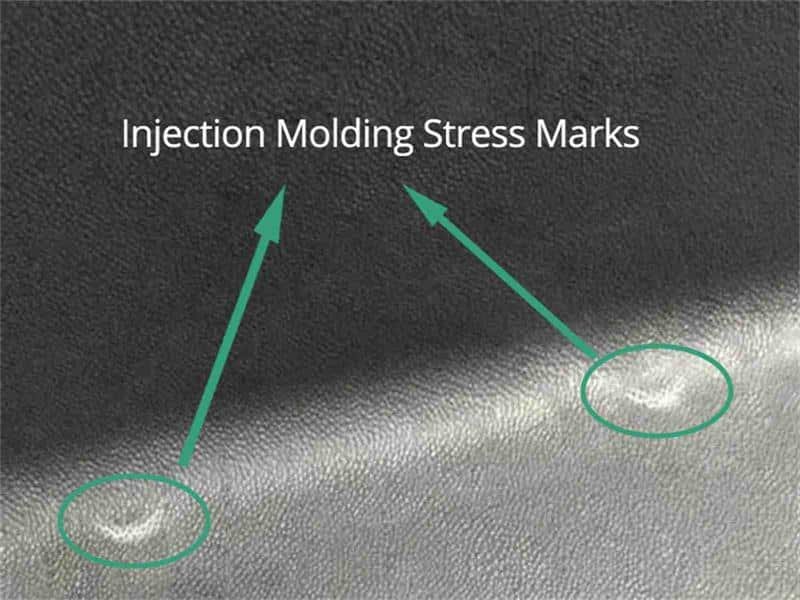

Shiny white marks on your molded parts signify internal stress. You must acknowledge that ignoring

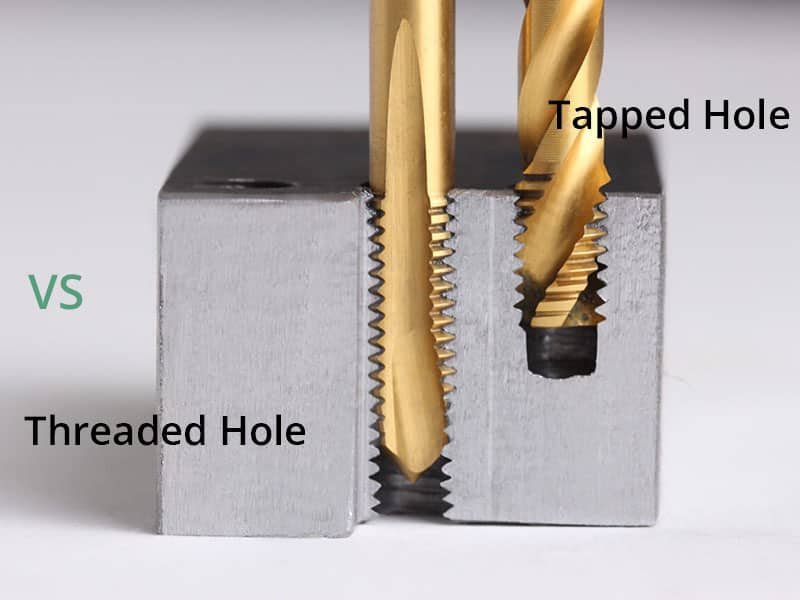

Tapped holes and threaded holes play crucial roles in joining plastic parts or plastics to

Jetting in injection molding creates worm-like defects when molten plastic shoots through the gate unchecked.