POM Machining Service for CNC Parts

We Provide POM Machining Service to Match Your Needs!

- Tight tolerances, typically ±0.05 mm or better

- Smooth surface finish, suitable for moving parts

- Reliable performance from prototype to small production runs

- Machining process adjusted to minimize stress and deformation

- Good at integrating POM parts with metal assemblies

- Support from our engineering team for design and material selection

What is Machined POM (CNC Delrin)

POM CNC machining refers to using CNC milling or turning to cut POM (also called Acetal or Delrin®) into precise shapes. POM is a tough, low-friction plastic with good dimensional stability, which makes it ideal for tight-tolerance parts. It machines cleanly without melting or chipping, and it doesn’t absorb much moisture, so the final parts stay stable over time.

Types of POM Machining

POM Machining Material Properties

Here are some key properties of Delrin machining material. These values are typical and may vary depending on the grade and additives

| Item | Value |

|---|---|

| Density | ~1.41 g/cm³ |

| Tensile Strength | ~60–70 MPa |

| Elongation at Break | ~20–40% |

| Flexural Modulus | ~2,500 MPa |

| Impact Strength (Notched) | ~3–6 kJ/m² |

| Max Operating Temperature | ~100–110°C |

| Water Absorption (24h) | <0.2% |

-

Benefits of POM CNC Machining

- POM machines cleanly and holds tight tolerances, even on complex parts.

- The material has low friction and good wear resistance, making it great for moving parts.

- It absorbs very little moisture, so dimensional stability stays consistent.

- Strong and rigid, it can take mechanical stress without warping or cracking.

- Surface finish after machining is smooth without much post-processing.

-

Shortcomings of POM CNC Machining

- It can be tricky to bond or glue—parts usually need to be mechanically fastened.

- Not ideal for high-heat applications, as it softens around 100°C.

- Chips can be stringy and hard to evacuate during machining if not managed well.

- Can shrink slightly after machining, which may affect high-precision fits.

Popular Machining POM Products

Here are some popular POM machined parts we have made:

- Gears

- Bushings

- Rollers

- Spacers

- Pulleys

- Mounting brackets

- Structural support parts

Have a Question?

Additonal Options for Acrylic Parts

Related Delrin Machining Resources

Thermoforming vs injection molding, both are popular plastic manufacturing techniques. The two processes are good

Ejector pin marks are a common defect on molded parts, appearing either as indentations or

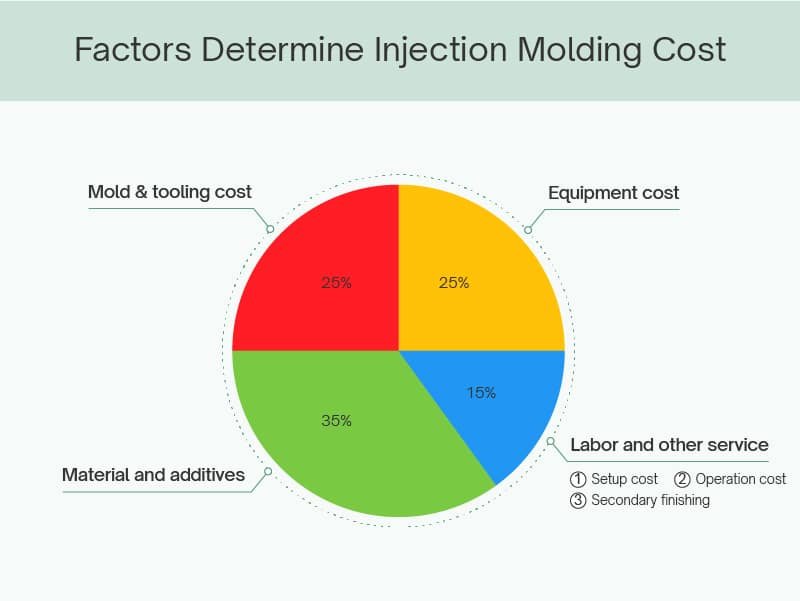

The injection molding cost varies depending on a variety of factors, such as material choice,