Custom Injection Molding Tooling Manufacturing

What is Tooling in Injection Molding

Injection molding tooling refers to the custom-designed mold used to shape the molten material into the desired final product. The tooling is a critical aspect of injection molding process as it determines the molded part's geometry, surface finish, and overall quality.

At Erye, all our injection mould and tooling are designed and produced in-house. Our production molds are typically made from durable materials like tool steel, which can withstand the high pressures and temperatures encountered during the injection molding process, able to withstand millions of shots.Types of Custom Mold & Tooling We Offer

Your Reliable Injection Mold Tooling Maker

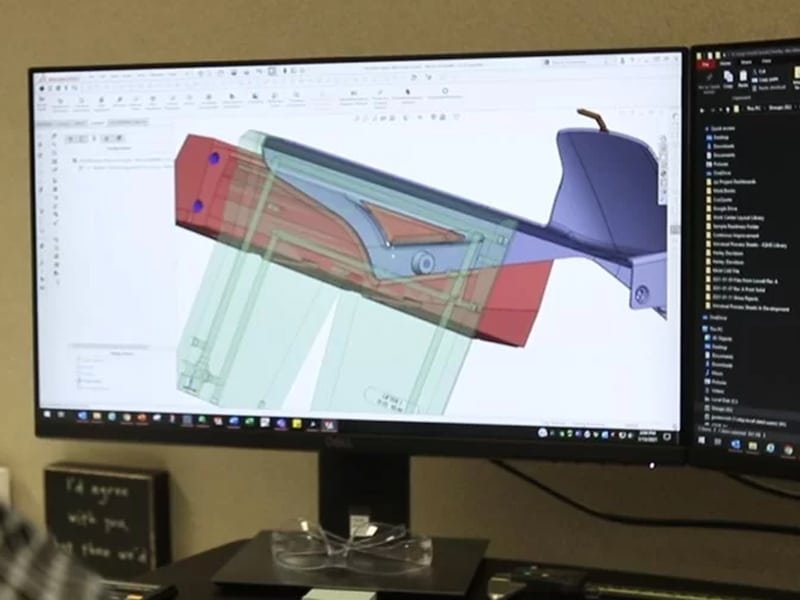

DFM & Mold Flow Analysis

At Erye, we offer DFM(Design for Manufacturability) report, our engineers evaluate the part design thoroughly to identify and resolve any potential challenges, to ensure the mold can be manufactured precisely and perform reliably during production.

By mold flow simulation, we analyze material flow dynamics, pinpoint areas prone to defects such as warping or voids, and optimize key features like gate locations and cooling channels.

Select the Right Mold Material

Tool Steel

- Low to high-volume production

- Types: P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738

Stainless Steel

- Expensive, only for large-scale production

- Types: 420, NAK80, S136, 316L, 316, 301, 303, 304

Aluminum

- Cost-effective, ideal for rapid prototype and low-volume production

- Types: Types: 6061, 5052, 7075

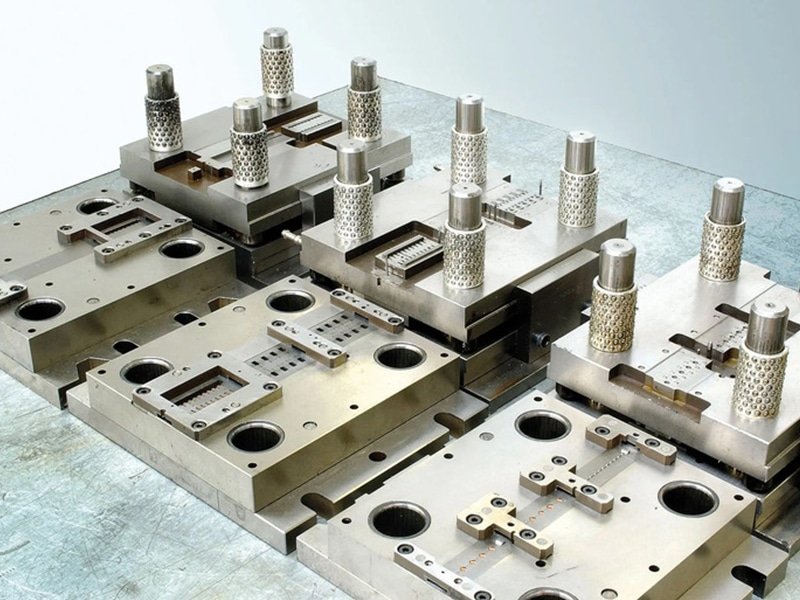

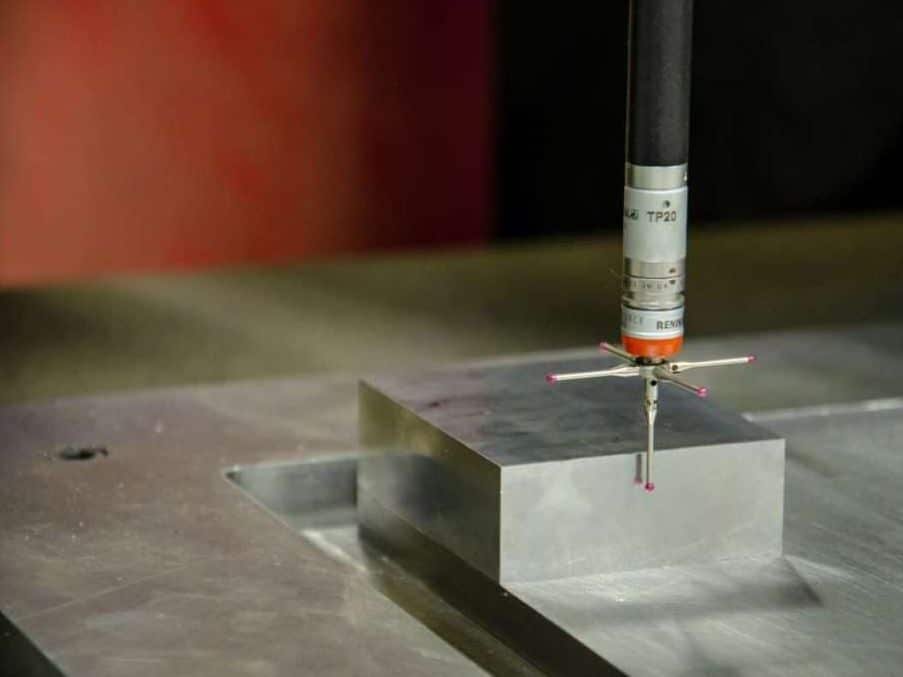

Advanced Equipment for Mold Production

As a China injection mold factory, our facility is equipped with over hundred of equipment, enable us to produce high-precision mold for complex and intricately structured molding components.

Our mold machine include:- CNC Machining Center

- EDM

- Wire Cutting Machine

- Lathing Machine

- Grinding Machine

- Drilling Machine

- Engraving Machine

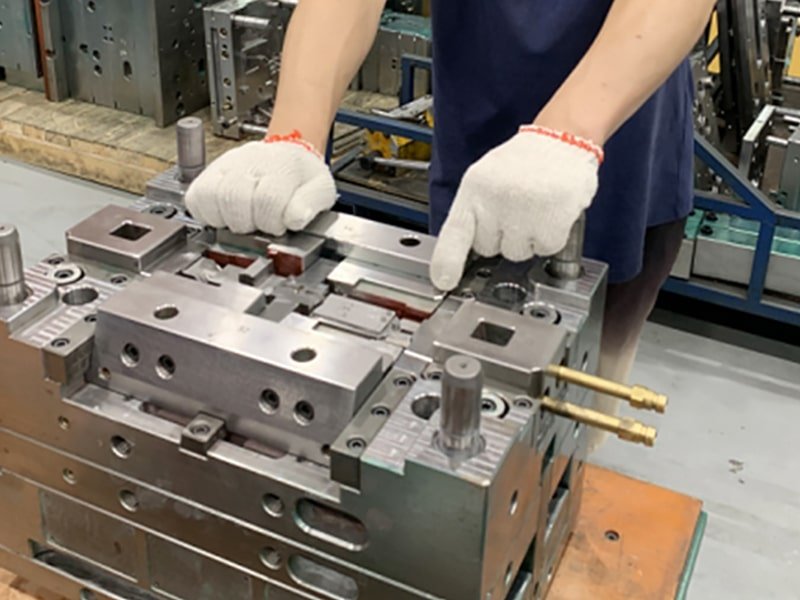

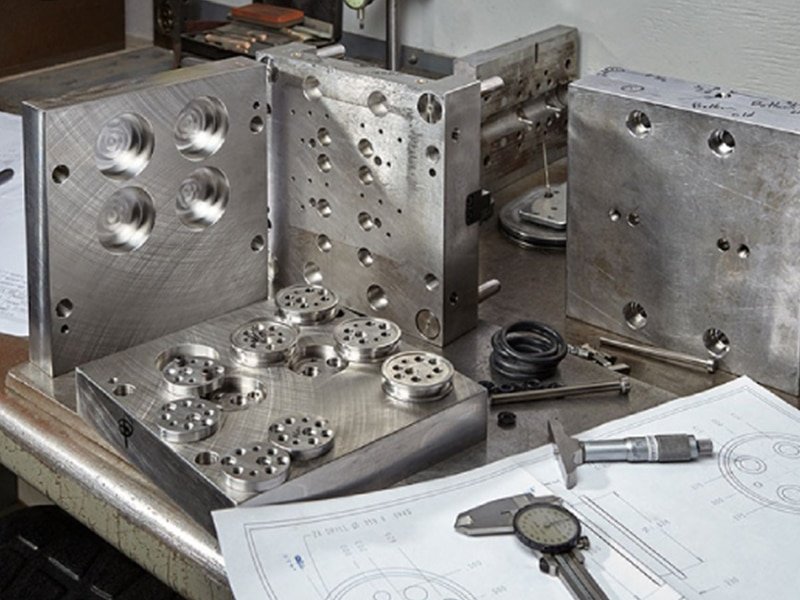

Precision Mold Polishing and Assembly

A well polished mold can enhance aesthetics and improve quality of the final product. At Erye, we strictly follow SPI and VDI standard according to customers' requirement.

The final assembly process ensure that all mold componetns fit together, and then we run mold trails in-house to make T1 sample to have a clear vision of how the customers' final molded parts will turn out.Mold Quality Assurance

Start Injection Molding Tooling Project

Injection Mold Capabilities

| Class | Purpose | Shot Life | Tolerance | Cost | Lead Time |

|---|---|---|---|---|---|

| Class 105 | Prototype Testing | Under 500 cycles | ± 0.02mm | $ | 7-10 days |

| Class 104 | Low-volume Production | Under 100.000 cycles | ± 0.02mm | $$$ | 10-15 days |

| Class 103 | Low-volume Production | Under 500.000 cycles | ± 0.02mm | $$$$ | 10-15 days |

| Class 102 | Medium-volume Production | Under 1,000,000 cycles | ± 0.02mm | $$$$$ | 10-15 days |

| Class 101 | High-volume Production | Over 1,000,000 cycles | ± 0.02mm | $$$$$$ | 10-18 days |

Related Resources for Injection Mold

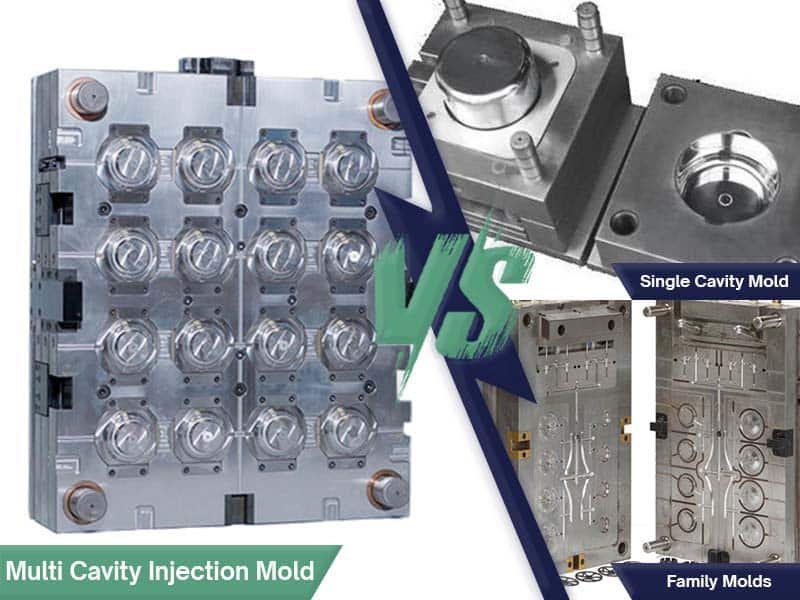

In injection molding, a cavity is the hollow (negative) space inside a mold that defines

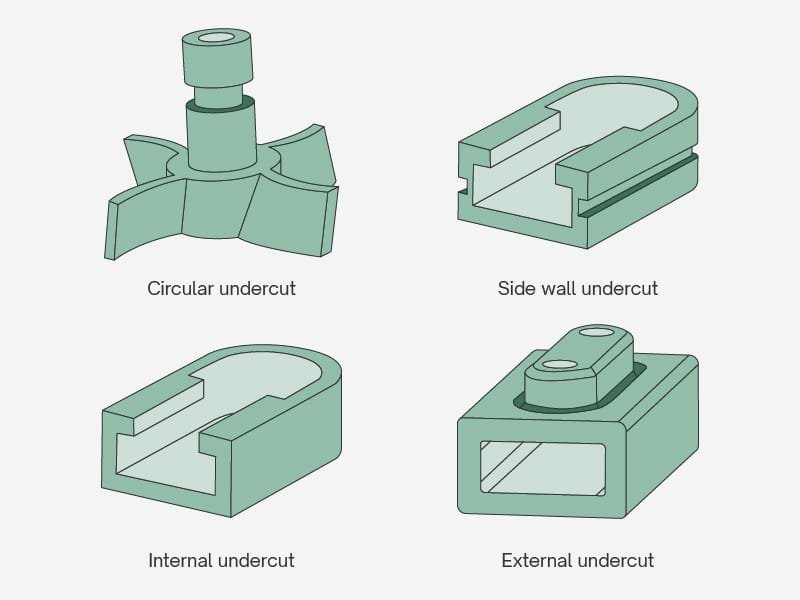

Injection molding undercuts is any protrusion or recessed feature on a plastic part that prevents

Injection molding is popular in various industries, from automotive to healthcare, as a technical force

Injection molding gate design is a critical factor that directly impacts the quality, efficiency, and

Design for Manufacturing (DFM) is a critical approach that bridges the gap between product design

Injection molding mold parts, ranging from the mold base structure to the ejection system, work