Large Part Injection Molding

Large Part Injection Molding

Large part injection molding is a complex process that requires specialized equipment and expertise. Our team has extensive experience in plastic molding large parts across a variety of industries. We’ve upgraded our high-tonnage machines with extended-capacity injection units and reinforced tie-bars so they can reliably fill and clamp very large molds.

- Injection molding machines with a range of 450 to 1100 tons;

- Automated robotic arms for consistent, accurate part handling;

- Custom mold design and manufacturing capabilities;

- High-quality surface finishing options for a refined finish;

- Comprehensive assembly services to integrate complex components;

- In-depth testing and rigorous quality control processes;

- Flexible production runs for both small and large volumes.

Large Part Molding Specifications

| Service | Details |

|---|---|

| Process Materials | Most plastics and rubber, including custom sourcing, check our manufacturing material list for reference. |

| Standard Finishes | SPI and VDI |

| Press Sizes | 90 ~ 1100 tons |

| Maximum size | Plastic Part: 2500mm*2000mm Rubber Part: 3000mm*2500mm |

| Mold Service | DFM report and mold flow analysis |

| Mold Ownership | Customer owned with regular mold maintenance on us |

| Mold Cavities | Single or multi-cavities |

| Mold Life | Unlimited (If the mold worn out, Erye will cover the cost of new mold) |

Plastic Molding Large Parts Examples

Optimizing Large Part Injection Molding Process

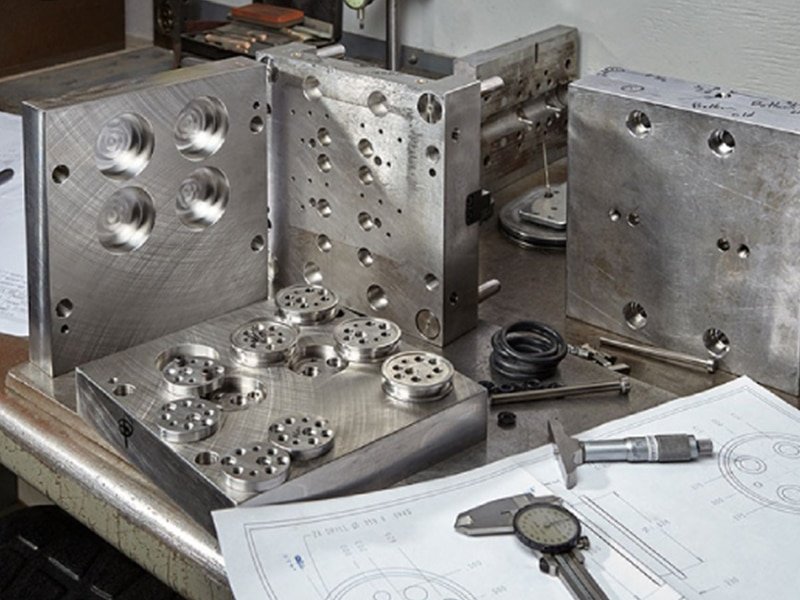

We design and produce all the mold in house, our facility is equipped with mulit-axis CNC center and EDM equipment to create high-precision molds that can handle high-tonnage injections, essential for large parts.

We use hardened tool steels, normally P20, 718H or upon request, to ensure longer mold lifespans, often exceeding 300,000 cycles. Furthermore, once the mold worn out, we will build a new set of mold with no extra fee your side.

2. Design for Manufacturability (DFM)

We work closely with your design team to identify and address potential production challenges early in the process. By assessing your large part designs for manufacturability, we help optimize designs to minimize production difficulties, reduce material waste, and lower overall costs.

Our DFM analysis includes suggestions for design adjustments that make molding easier and more efficient.

3. Material Selection

Choosing the right material is crucial for ensuring that your large parts meet performance requirements while being manufacturable at scale. We offer an extensive range of engineering-grade thermoplastics and elastomers such as ABS, PC, PP, TPU, etc., that are ideal for large parts, with properties such as strength, flexibility, and impact resistance.

We also provide expert guidance on material modifications using additives to enhance specific characteristics like UV resistance, flame retardancy, or improved tensile strength.

4. Finished Part Assembly and Testing

We offer complete finished part assembly services, ensuring all components are accurately aligned and securely joined. Our team pays close attention to the precision and fit of each part during the assembly process to guarantee optimal functionality.

In addition to assembly, we conduct a range of tests to validate that the assembled parts meet required performance and durability standards. This includes compatibility checks, strength assessments, and functional testing, ensuring that each final product performs as expected.

Large Car Dashboard Automotive Mold Case Study

Related Resources of Injection Molding

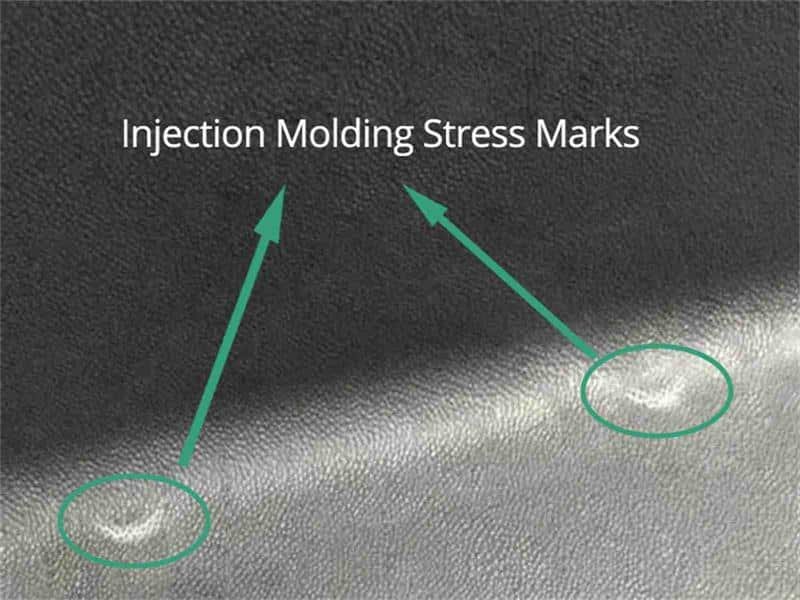

Shiny white marks on your molded parts signify internal stress. You must acknowledge that ignoring

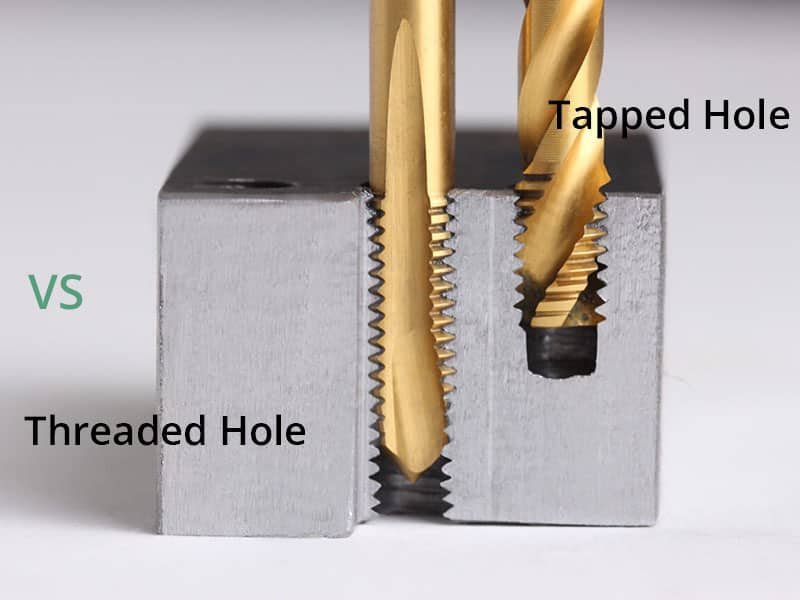

Tapped holes and threaded holes play crucial roles in joining plastic parts or plastics to

Jetting in injection molding creates worm-like defects when molten plastic shoots through the gate unchecked.