Assembly Solution for Custom Manufacturing

Contract Assembly Manufacturing

At Erye, we can provide end-to-end assembly solutions that ensure all your custom molding components fit precisely and function well. We aware that poor fit, weak joints, or other performance issues can compromise the product quality, leading to failures for final use. Our assembly solutions address these challenges with advanced fastening methods, precision alignment, and material compatibility expertise.

Our Assembly Service

- Mechanical Assembly – Press-fit, threaded fasteners, snap-fit connections

- Bonding Methods – Ultrasonic welding, solvent bonding, industrial adhesives

- Sealing & Leak Testing – Waterproofing, airtightness verification

- Functional & Load Testing – Structural integrity, movement validation, electrical performance checks

- Custom Packaging & Labeling – Retail-ready packaging, private labeling

- Component Sourcing & Logistics – Procurement and supply chain support

Our Comprehensive Assembly Capabilities

Manual Assembly

- Prototype or short-run production

- Complex or delicate components

- High customization requirements

Semi-Automated Assembly

- Medium production volume

- Improved speed and consistency

- Repetitive tasks with some complexity

Fully Automated Assembly

- High production volume

- Minimal human intervention

- Consistent output with reduced errors

End-to-End Assembly Solutions

Quality Control and Testing

Our engineers perform assembly testing for every project, we are able to adjust assembly default promptly as we can fix all the components in house. From production to assembly process, we monitor robust quality control at every step, ensuring the assembly parts fit well to meet the required specifications and functionality. Our testing includes,

- Waterproofing

- Airtightness

- Electrical performance

- Structural integrity

- Load & pressing

Why Choose Erye for Assembly Manufacturing

Integrated Solutions

Streamlined Logistics

Customer-Centric Approach

Related FAQs of Assembly Service

Yes, we have extensive experience assembling various electronic components, such as PCBs, sensors, and circuit boards.

Yes, we cater to both low and high-volume assembly requirements.

Related Resources

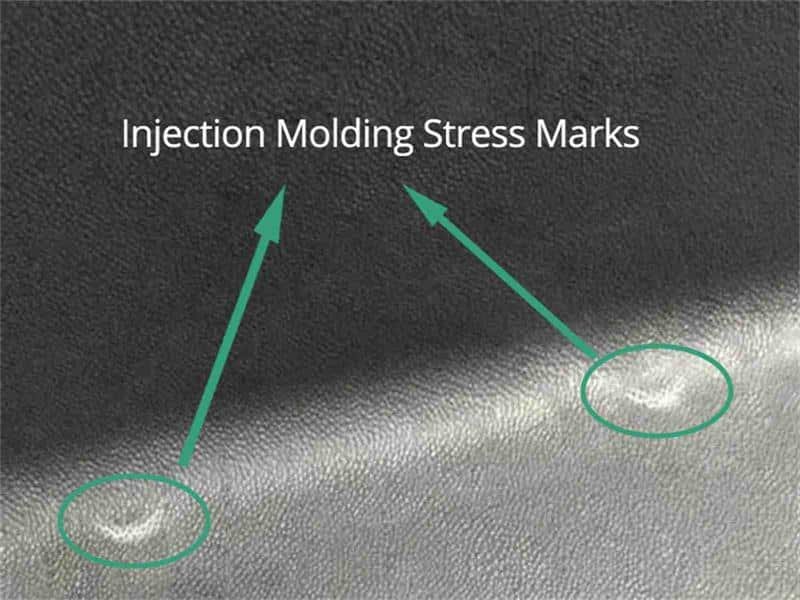

Shiny white marks on your molded parts signify internal stress. You must acknowledge that ignoring

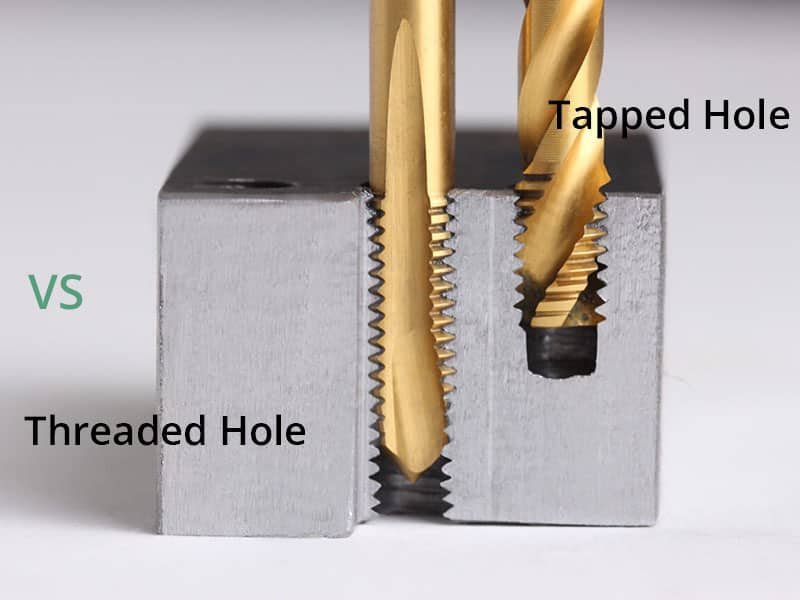

Tapped holes and threaded holes play crucial roles in joining plastic parts or plastics to

Jetting in injection molding creates worm-like defects when molten plastic shoots through the gate unchecked.