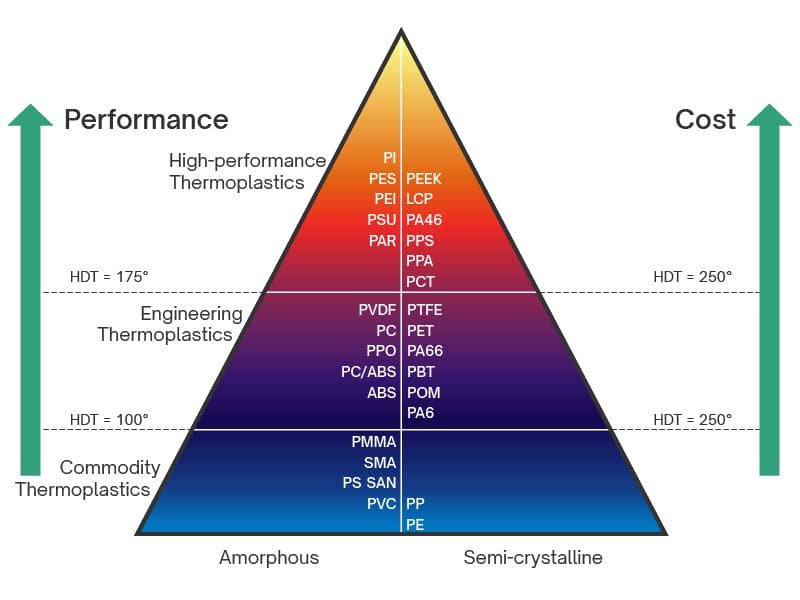

Compared to traditional materials such as metals, ceramics, and laminated glass, plastic has the disadvantage of relatively low heat resistance, which typically limits its use in high-temperature environments. This characteristic stems from the molecular composition of plastics, which can soften or degrade more readily under heat stress.

Among plastic raw materials, different types exhibit varying levels of heat resistance; some have poor high-temperature tolerance, while others perform significantly better. High-temperature plastics are generally defined as those with a Heat Deflection Temperature (HDT) above 200 °C.

The principal metrics for evaluating the heat resistance of plastic products include Heat Deflection Temperature (HDT), Vicat Softening Temperature (VST), and Continuous Service Temperature or the Relative Thermal Index, RTI. Among these, HDT is the most commonly used.

For a given plastic, the relative sequence of these heat-resistance parameters typically is:

Vicat Softening Temperature > Heat Deflection Temperature > Continuous Service Temperature (e.g. RTI or related index).

Types of Heat-Resistant Plastics

Plastics can be classified by their long-term service temperature into three categories: commodity (general-purpose) plastics, engineering plastics, and high-temperature engineering plastics (also known as heat-resistant plastics, high-performance plastics, or specialty engineering plastics).

Commodity (General-Purpose) Plastics: Typical long-term use temperature: below 100 °C. Common examples include PE, PP, PS, PVC, ABS, which are used in packaging, daily household items, and toys.

Engineering Plastics: Long-term service temperature: approximately 100 °C to 150 °C. Typical examples include PA (polyamide/nylon), POM (polyoxymethylene), PBT (polybutylene terephthalate), PC (polycarbonate), and PPO. These are typically used in mechanical components, automotive parts, and electrical/electronic devices.

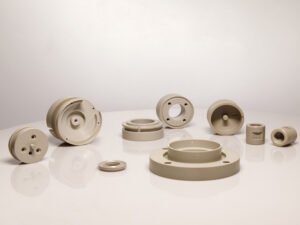

High-Temperature Engineering Plastics: Long-term service temperature: above 150 °C; classification equivalent to high-performance or specialty engineering plastics. In addition to superior thermal resistance and flame-retardancy, they often exhibit excellent machinability, aging resistance, dimensional stability, and electrical performance. They can substitute metals and are widely applied in electronics, aerospace, medical devices, automotive, and military industries, it is the top-tier material in the plastic pyramid.

Top 5 Heat Resistant Plastic Materials

Selecting the right material for high-temperature applications can make all the difference in performance and durability. Below are the five most commonly used heat-resistant plastics that excel in withstanding extreme temperatures without compromising structural integrity. Each material offers unique properties suited for various industrial needs.

PAI (Polyamide-imide)

PAI is known for its impressive thermal stability and can handle continuous exposure to temperatures up to 260 °C (500 °F). This material is ideal for applications that require both high thermal and mechanical strength. PAI can withstand short-term exposures to temperatures as high as 275°C (527°F) without significant degradation. The material’s exceptional resistance to wear, fatigue, and chemicals further extends its lifespan in industries such as aerospace, automotive, and manufacturing.

Key Benefits:

- Superior mechanical strength and rigidity

- Excellent wear resistance and low friction

- Outstanding resistance to chemicals and radiation

- High electrical insulating properties

PAI is used in aerospace, automotive, and industrial applications, including bearings, gears, electrical connectors, and seals, where high temperatures and mechanical stress are prevalent.

PTFE (Polytetrafluoroethylene)

PTFE, often referred to as Teflon™, discovered by accident at DuPont in 1938, offers remarkable heat resistance, maintaining its physical properties at temperatures as high as 260°C (500°F) for continuous exposure. This material can even withstand short-term thermal exposure up to 300°C (572°F) without showing signs of degradation. This is due to its strong carbon-fluorine bonds, which resist thermal degradation. PTFE maintains dimensional stability because of its low coefficient of thermal expansion. Although PTFE has high thermal stability, its tensile strength and elongation can decrease at high temperatures

Key Benefits:

- Superior chemical resistance

- Non-stick and low friction properties

- Excellent electrical insulation

- High dimensional stability

PTFE is commonly used in chemical processing industries, as well as in food production, automotive applications, and electrical industries for seals, gaskets, bearings, and insulating components.

PEEK (Polyether Ether Ketone)

PEEK (Polyetheretherketone) is a high temperature plastic known for its exceptional properties under high temperatures. It maintains continuous operation up to 250°C (482°F) and can briefly withstand up to 310°C (590°F) without significant degradation. PEEK’s thermal stability ensures minimal degradation, even in extreme environments, and it exhibits strong resistance to a variety of chemicals. Mechanically, it boasts high tensile strength and stiffness, along with good impact resistance. PEEK also exhibits excellent electrical properties, a low coefficient of thermal expansion for dimensional stability, and a V-0 flammability rating, indicating strong flame retardancy.

Key Benefits:

- High chemical and radiation resistance

- Outstanding mechanical properties (high tensile strength, low wear)

- Superior dimensional stability under stress

- Excellent fatigue resistance and low friction

PEEK is widely used in industries like aerospace, automotive, and medical fields, particularly for components such as seals, bearings, connectors, and valves.

PPS (Polyphenylene Sulfide)

PPS is a high-temperature thermoplastic known for its impressive resistance to heat, chemicals, and oxidation. It can maintain its mechanical properties at temperatures up to 220°C – 230°C (428°F – 446°F ). PPS is also known for its excellent electrical insulating properties and is widely used in demanding applications. It offers high resistance to thermal degradation and exhibits high chemical stability, making it suitable for long-term use in harsh environments.

Key Benefits:

- Exceptional chemical resistance

- High dimensional stability and mechanical strength

- Excellent electrical insulation properties

- Long-term thermal stability

PPS is frequently used in automotive, electrical, and chemical processing industries, particularly for components like pumps, valves, and electrical connectors that are exposed to high temperatures and harsh conditions.

PEI (Polyetherimide, Ultem)

Polyetherimide (PEI), also known as Ultem, is an amorphous thermoplastic that maintains its strength and rigidity at elevated temperatures. This material has an extremely high melting point of 219°C (426°F) and a maximum continuous service temperature of 170°C (338°F). PEI offers excellent resistance to high-energy radiation, hydrolysis, and a range of chemicals, though it can be attacked by strong bases. PEI’s stable electrical properties over a wide range of frequencies and inherent flame retardancy make it suitable for electrical and electronic insulators. Its dimensional stability ensures it resists deformation under mechanical and thermal stress.

Key Benefits:

- Excellent mechanical strength and rigidity

- Good electrical insulating properties

- Resistant to a broad range of chemicals

- High dimensional stability under heat and stress

PEI is frequently used in aerospace, automotive, electrical, and medical industries for connectors, insulators, and structural components that require both heat and electrical resistance.

Tips to Choose High Temp Plastics

1. Define the Operating Temperature

Determine the maximum and minimum temperatures of the environment in which the material will be used. For continuous exposure to temperatures above 200°C (392°F), consider PEEK or Polyimide. For lower ranges, PEI or PPS may suffice.

2. Consider Mechanical Load and Stress

Evaluate the mechanical demands, such as tensile strength, impact resistance, and wear. PEEK is ideal for high-stress applications like aerospace components, while PTFE is better for low-friction, non-load-bearing uses like seals.

3. Assess Chemical Exposure

Identify any chemicals, solvents, or oils the material will encounter. PTFE and PPS offer excellent chemical resistance, making them suitable for chemical processing equipment.

4. Evaluate Electrical Requirements

If electrical insulation is needed, choose materials with high dielectric strength. For example, Polyimide and PEI are excellent for electrical insulators and connectors.

5. Check for Flame Resistance

For applications requiring flame retardancy, choose materials with inherent flame-resistant properties. PEI and PPS are naturally flame retardant, making them ideal for aerospace and automotive applications.

6. Consider Dimensional Stability

Ensure the material maintains its shape and size under thermal cycling or mechanical stress. PPS and PEEK have low thermal expansion, making them suitable for precision components.

7. Factor in Cost and Availability

Balance performance requirements with budget constraints. Some high-performance plastics like PEEK can be expensive. For cost-sensitive applications, PPS or PEI may offer a better balance of performance and affordability.

8. Evaluate Processing Requirements

Ensure the material is compatible with your manufacturing process (e.g., injection molding, machining). PEEK and PEI are easier to machine, while PTFE requires specialized processing due to its non-stick properties.

Challenges in Using Heat-Resistant Plastics

While heat-resistant plastics offer exceptional performance in high-temperature applications, their use does come with certain challenges. These include processing difficulties, compatibility with other materials, and the risk of wear and tear under extreme heat conditions.

They are Difficult to Process and Moldable

One of the main challenges with high-temperature plastic materials is their processing complexity. High-performance thermoplastics such as PEEK and PAI (polyamide-imide) often require specialized processing equipment due to their high melting points. In many cases, these may need to be processed at even higher material temperatures and pressures, which are difficult to achieve with standard injection molding equipment. This can significantly increase production costs and lead times.

Moldability is also a concern, as some heat resistant plastics tend to have poor flow properties, and the high viscosity of these plastics at elevated temperatures makes it difficult to uniformly fill the mold, making it difficult to form complex geometries or fine detail molded parts. This may require more advanced mold design or post-processing work to achieve the desired results.

They Are Not Easy to Comply with Other Materials

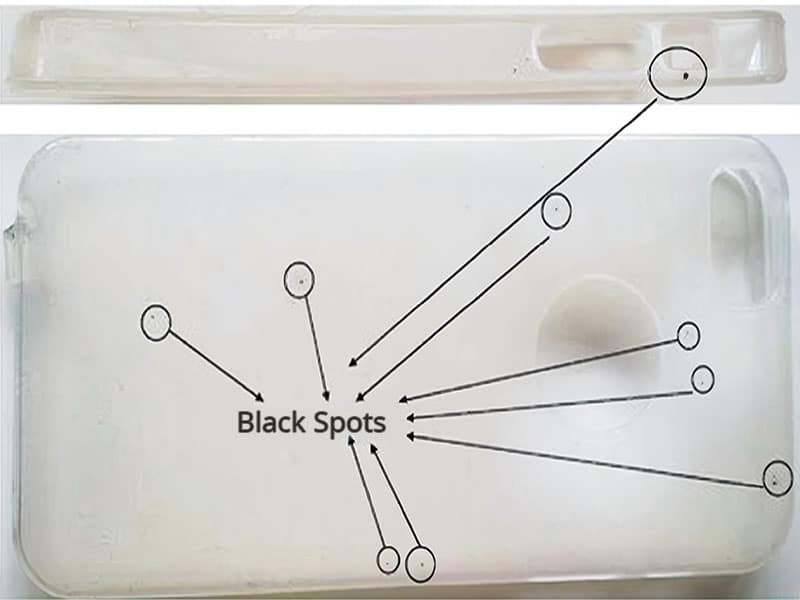

In many applications, heat-resistant plastics often combine with other materials, such as metals or other plastics. Ensuring compatibility between different materials, especially when exposed to high temperatures, can be tricky. Some high-temperature thermoplastics may have expansion rates or thermal conductivities that differ significantly from those of other materials, leading to injection molding defects like warping, cracking, or delamination during temperature fluctuations.

Additionally, heat-resistant plastic materials may not adhere well to certain metals or other types of plastics, making it difficult to achieve strong bonds without additional adhesives or surface treatments. These compatibility issues must be carefully considered during the design and material selection process to ensure long-term functionality and durability.

May Get Wear and Tear Under High Temperatures

While high temperature resistant plastics can withstand extreme temperatures, they are not immune to wear and tear. Under continuous exposure to high temperature, even the most heat-resistant plastics can experience degradation of their properties, such as reduced tensile strength and impact resistance, and a lack of surface integrity. This is especially true for plastics that are used in environments where they are subjected to constant mechanical stress or abrasive environments.

Over time, the combination of high heat and physical wear can lead to material fatigue. For example, polyphenylene sulfide (PPS) and polyimide (PI), while very strong at high temperatures, can still suffer from microcracks, discoloration, or dimensional stability loss under thermal cycling or friction. To mitigate these effects, regular monitoring and maintenance are critical in environments where high-temperature plastics are used for extended periods of time.

Choose an Expert Manufacturer to Help With Material Selection

The importance of selecting the appropriate heat-resistant plastic cannot be overstated in high-performance applications. Choosing the right material ensures optimal performance under demanding conditions, maintaining both the physical and mechanical integrity of the product over time. Whether for aerospace, automotive, or electronics, the correct high-temperature plastic material can make a substantial difference in the reliability and longevity of the components. For complex requirements, consulting with material experts or suppliers can provide additional insights and recommendations.

If you’re looking for expert advice and high-quality solutions, Erye the molding material expert are here to guide you every step of the way. Contact us today for a quote!